Hydraulic infinitely-variable-speed drip irrigation tape recycling machine

A hydraulic stepless variable speed and drip irrigation belt technology, which is applied in the field of agricultural machinery, can solve the problems of wasting time and manpower, delaying spring planting, and being unable to quickly remove it, so as to save costs and reduce labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

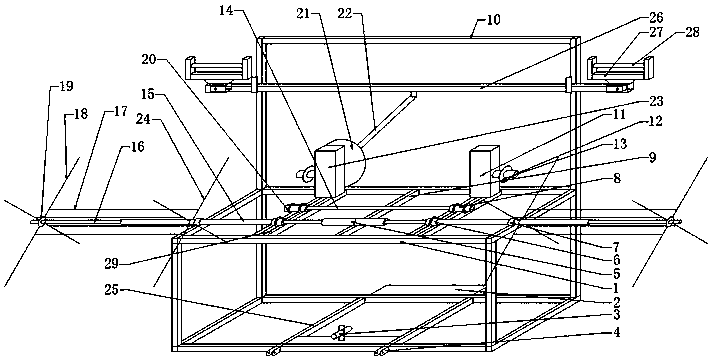

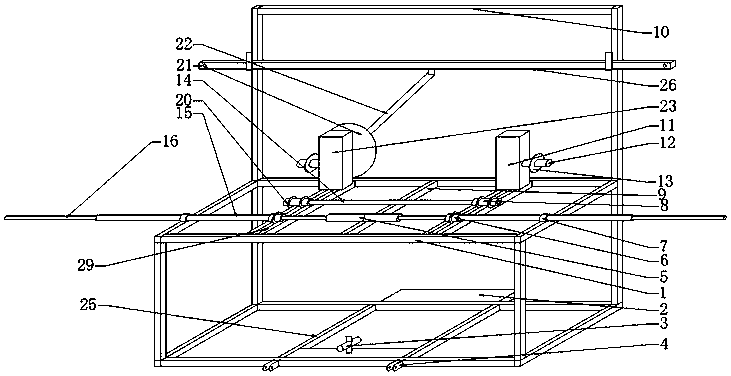

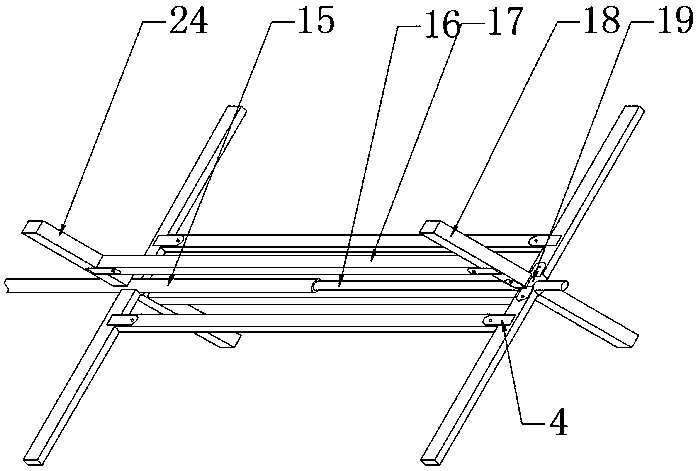

[0016] Example 1, such as Figure 1~Figure 4 As shown, a hydraulic continuously variable speed drip irrigation belt recovery machine includes an iron frame 1, the top of the iron frame 1 is provided with a handrail 10, the lower side of the handrail 10 is provided with a support rod 26, and the two ends of the support rod 26 are A supporting frame 27 is provided, a rotating shaft 28 is arranged on the upper part of the supporting frame 27, an upper beam 9 is arranged on the middle part of the iron frame 1, a lower beam 25 is arranged on the bottom of the iron frame 1, an iron plate is arranged between the lower beams 25, and an iron plate is arranged on the iron plate. A hydraulic gear pump 3, an ear plate 4 is provided at the front of the iron frame 1, a standing plate 2 is provided at the rear of the iron frame 1, a fixing ring 7 is provided at the upper part of the iron frame 1, a hydraulic cylinder 5 is provided on the upper beam 9, and a hydraulic cylinder 5 Including a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com