Torsion damper gear

A gear and torque technology, applied in the field of electric transmissions, can solve the problems of impact, affecting the normal wear and tear of gearbox gear connections, and setbacks, and achieve the effect of solving setbacks and impact, improving reliability and driving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

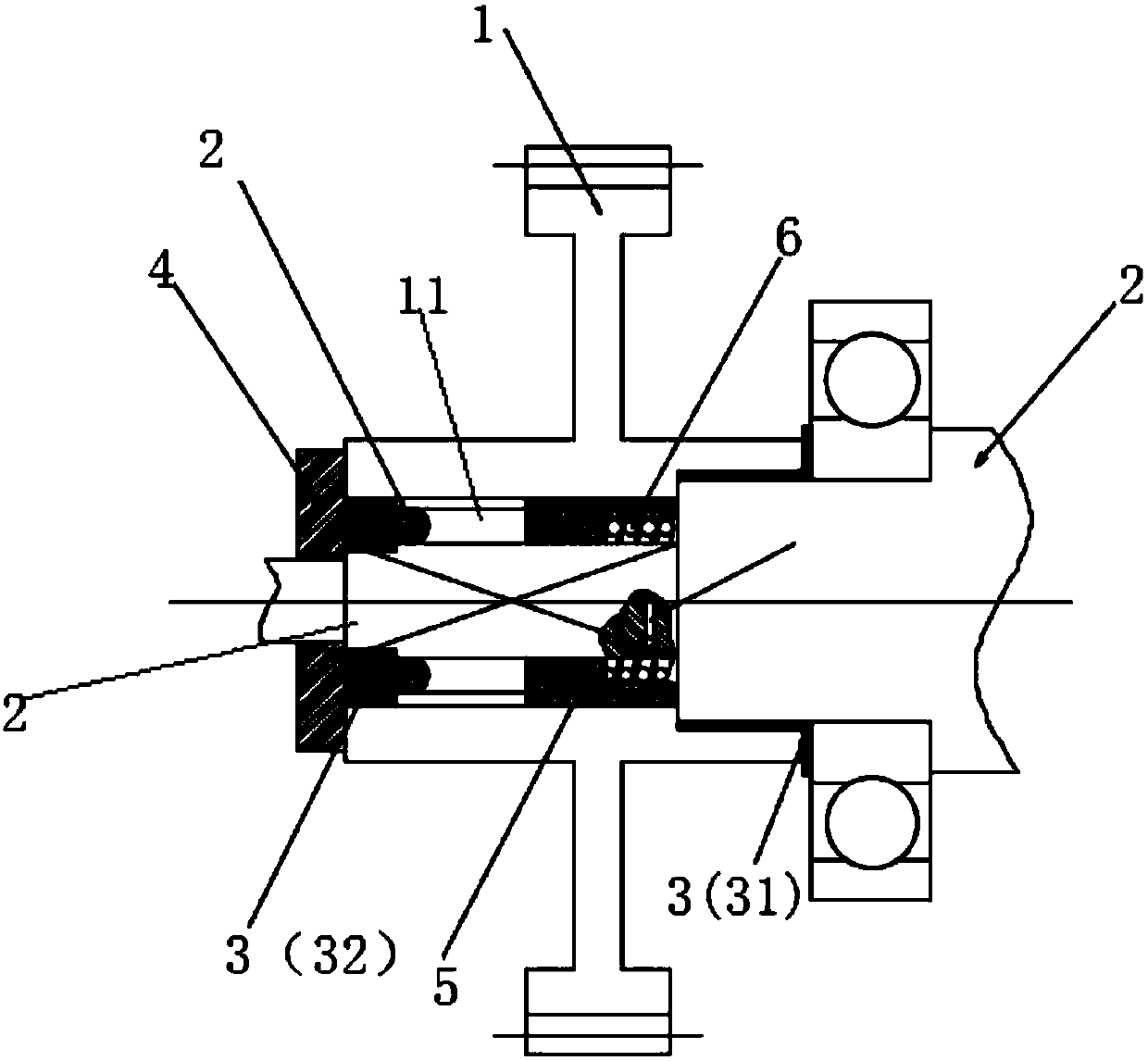

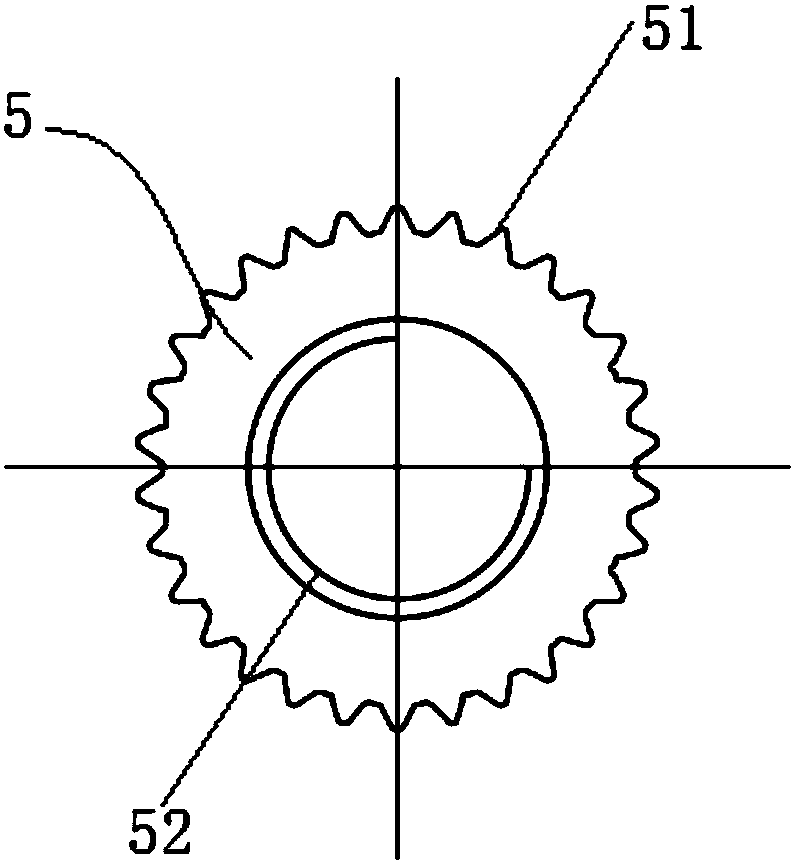

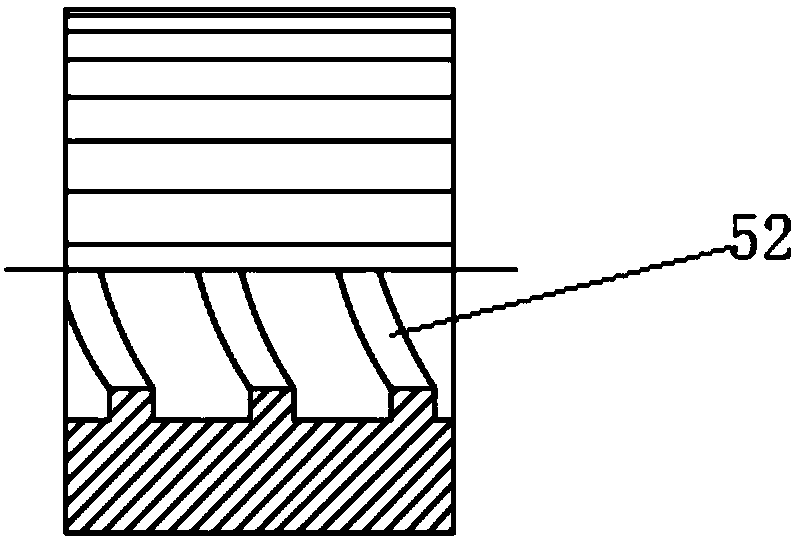

[0014] See figure 1 Shown is a schematic structural diagram of this embodiment. The torsion damping gear of this embodiment includes a transmission gear 1, a transmission shaft 2, a bearing 3 (or bushing), a lock nut 4, a sliding block 5, a spring 6, and a damping ring 7 and other components. Please combine the specific structure figure 1 And the following explanation:

[0015] The transmission gear 1 is provided with an axial inner hole 11, and an inner spline is provided on the wall of the inner hole 11. The internal splines are matched with the slider 4. The right end of the transmission shaft 2 is fixed in the inner hole 11 of the transmission gear 1 through a first bearing 31 and a second bearing shaft 32. The diameter of the right end of the transmission shaft 2 is higher than the diameter of the inner hole 11, forming a stepped shape. The material of the first bearing 31 and the second bearing shaft 32 is a pad bearing anti-friction material, whose function is to determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com