A multi-layer cmy color mixing system and optical path system

A technology of color mixing and color mixing unit, which is applied in the direction of electric light source, fixed light source, and optical elements used to change the spectral characteristics of emitted light, etc. It can solve the problems of inconvenient stage art design and slow cutting in and out speed of a single color mixing chip. achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

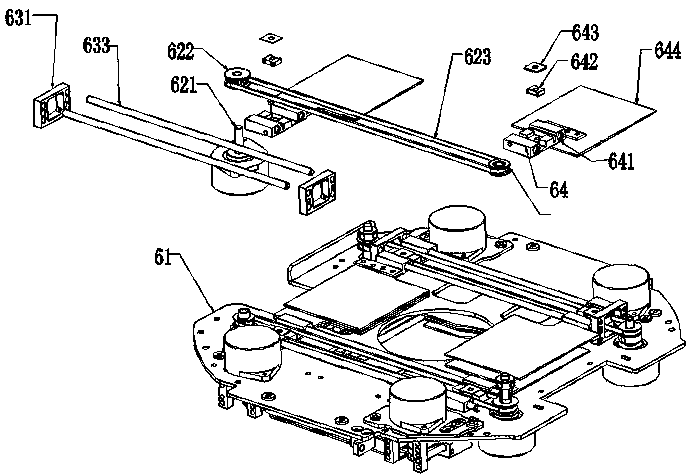

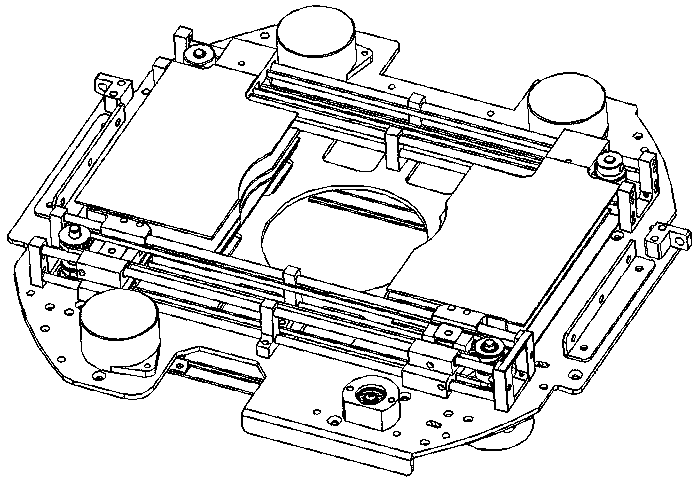

[0030] A schematic diagram of a multi-layer CMY color mixing system in this embodiment is as follows Figure 1 to Figure 2 As shown, it includes a CMY fixed frame 61 and a multi-layer color mixing unit fixed thereon. The CMY fixed frame 61 is provided with a through hole; each layer of color mixing unit includes two motion units, and each motion unit includes a CMY motion assembly 64, a fixed The CMY color mixing sheet 644 on the CMY moving assembly 64 and the driving device that drives the CMY moving assembly 64 to move; the two driving devices drive the CMY moving assembly 64 to move toward each other so that the corresponding two CMY color mixing sheets 644 are closed on the through hole. Light.

[0031] When using the multi-layer CMY color mixing system 6, install it on the stage lamp, and make the through hole face the exit direction of the light source 2; when the color mixing effect is required, control the two driving devices to drive the CMY moving assembly 64 to move t...

Embodiment 2

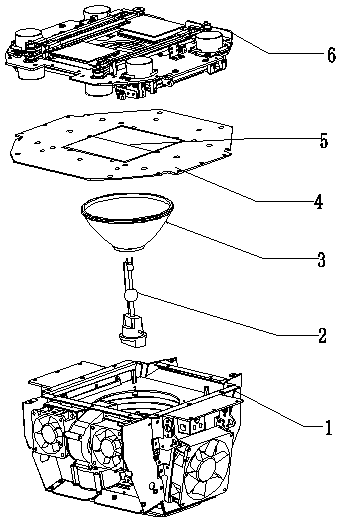

[0046] This embodiment provides an optical path system, the schematic diagram of which is shown in image 3 As shown, it includes any one of the above two multi-layer CMY color mixing systems 6, and the lamp holder system fixing frame 4, reflective cup 3, light source 2 and fixing seat 1 which are sequentially arranged under the multi-layer CMY color mixing system 6; The cup 3 and the light source 2 are fixed in the fixed seat 1, and the fixed seat 1 is provided with a heat dissipation system. The fixed seat 1 is fixed on the lamp holder system fixing frame 4, and the lamp holder system fixing frame 4 is provided with a heat insulating sheet 5.

[0047] The optical path system of the invention has multiple color mixing effects and brings convenience to stage art design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com