Jet-flow type gas sensation system applicable to security examination and method

A sensing system and safety inspection technology, applied in the analysis of gas mixtures, the structural details of gas analyzers, sampling, etc., can solve the problems of loss of life and property, limited measurement range, unreasonable flow field organization, etc., to achieve high reliability, The effect of increasing the firing range and increasing the amount of gas trapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

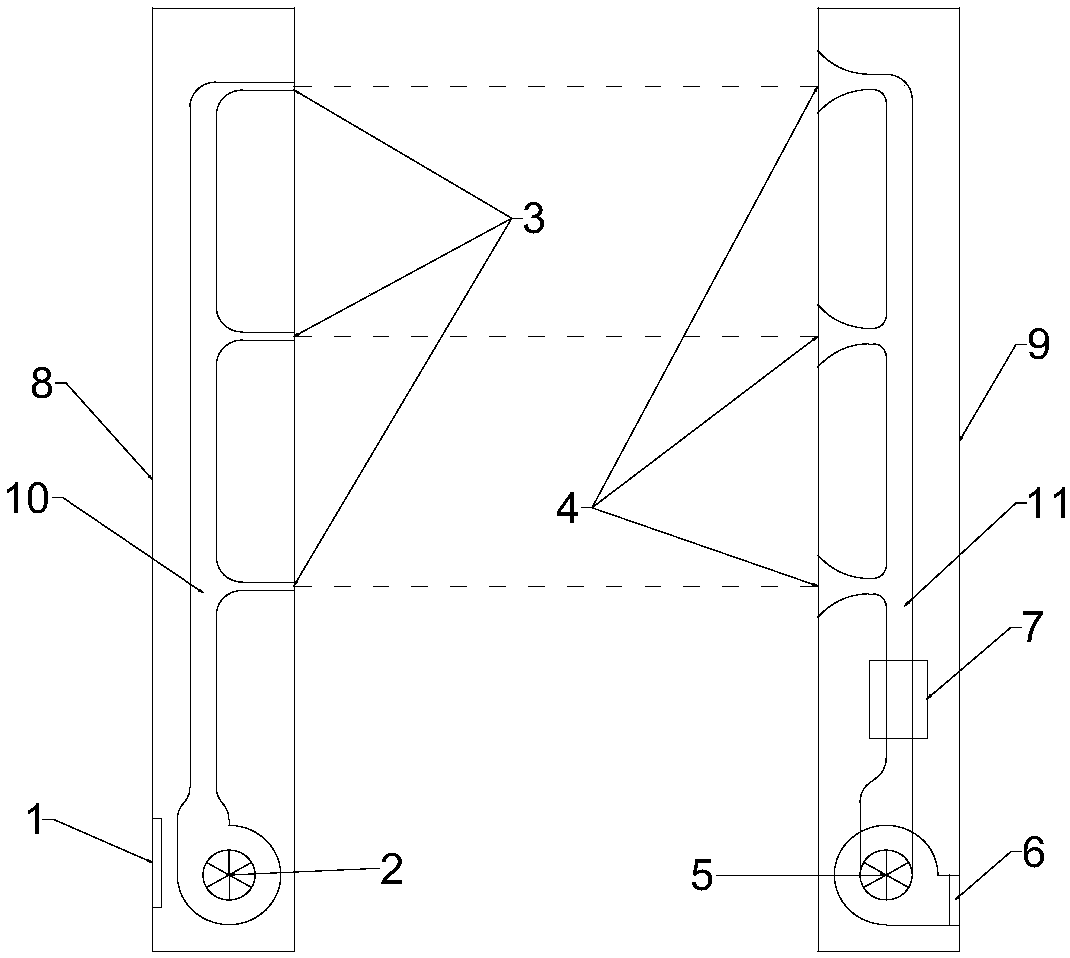

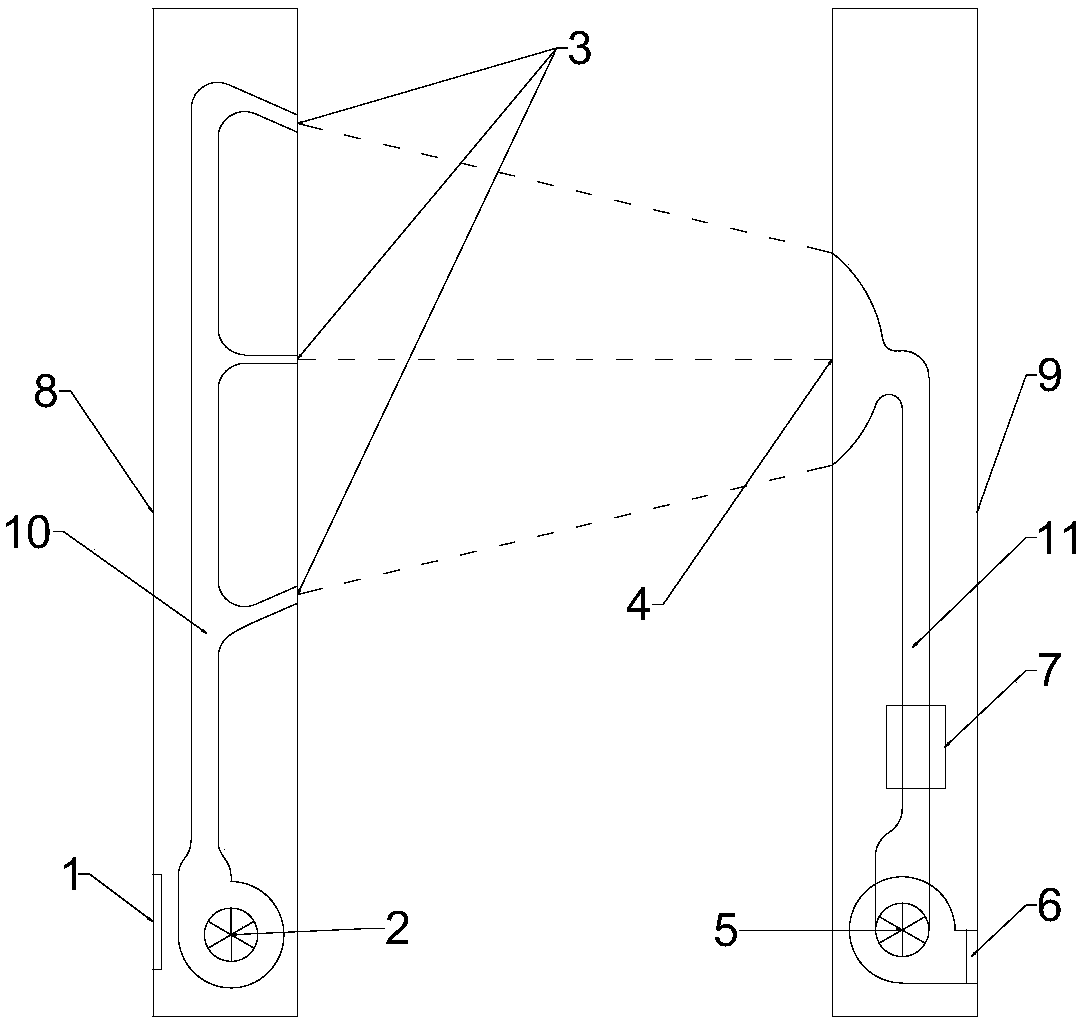

[0024] Attached below figure 1 And attached figure 2 Introduces the working method of the jet fan and suction gas induction system suitable for safety inspection: under the action of the blower 2, the gas is ejected through the jet nozzle 3 arranged on the air supply pipe 10, driving the air supply column 8 and the gas The gas in the middle of the detection column 9 flows to the gas capture port 4 together. When the gas reaches the vicinity of the capture port 4, it is sucked into the gas detector 7 by the induced draft fan 5, and then passes through the induced draft fan 5 from the bottom of the gas detection column 9. The air outlet 6 discharges, and when the gas to be detected is contained in the gas between the air supply column and the gas detection column, the gas detector 7 sends out an audible and visual alarm.

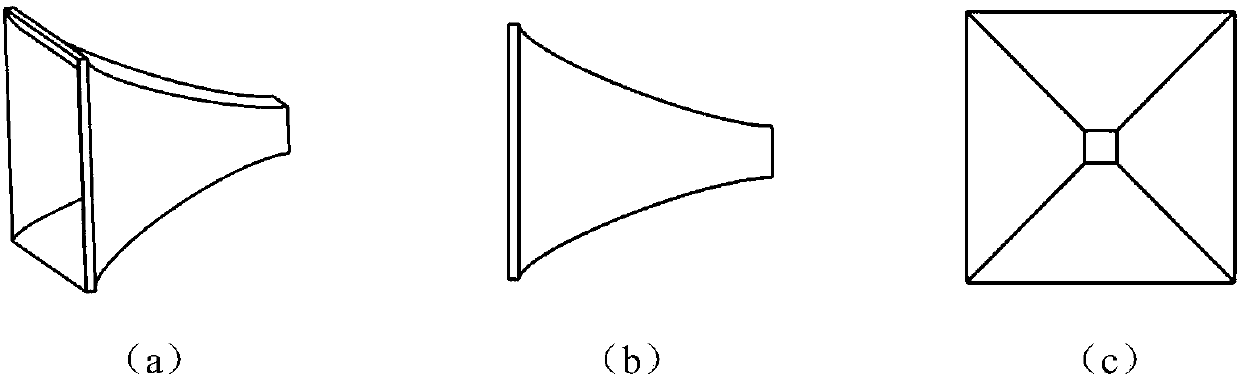

[0025] A special jet nozzle is installed on the air pipe on the air supply column, which not only improves the air supply range, but also ensures that the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com