Diluted Ubbelohde viscometer

A Ubbelohde viscometer and scale technology, which is applied in viscometer maintenance, flow characteristics, measuring devices, etc., can solve the problems of inconvenient liquid addition, large measurement error, uneven stirring, etc., and achieve easy operation, long service life, The effect of convenient production and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

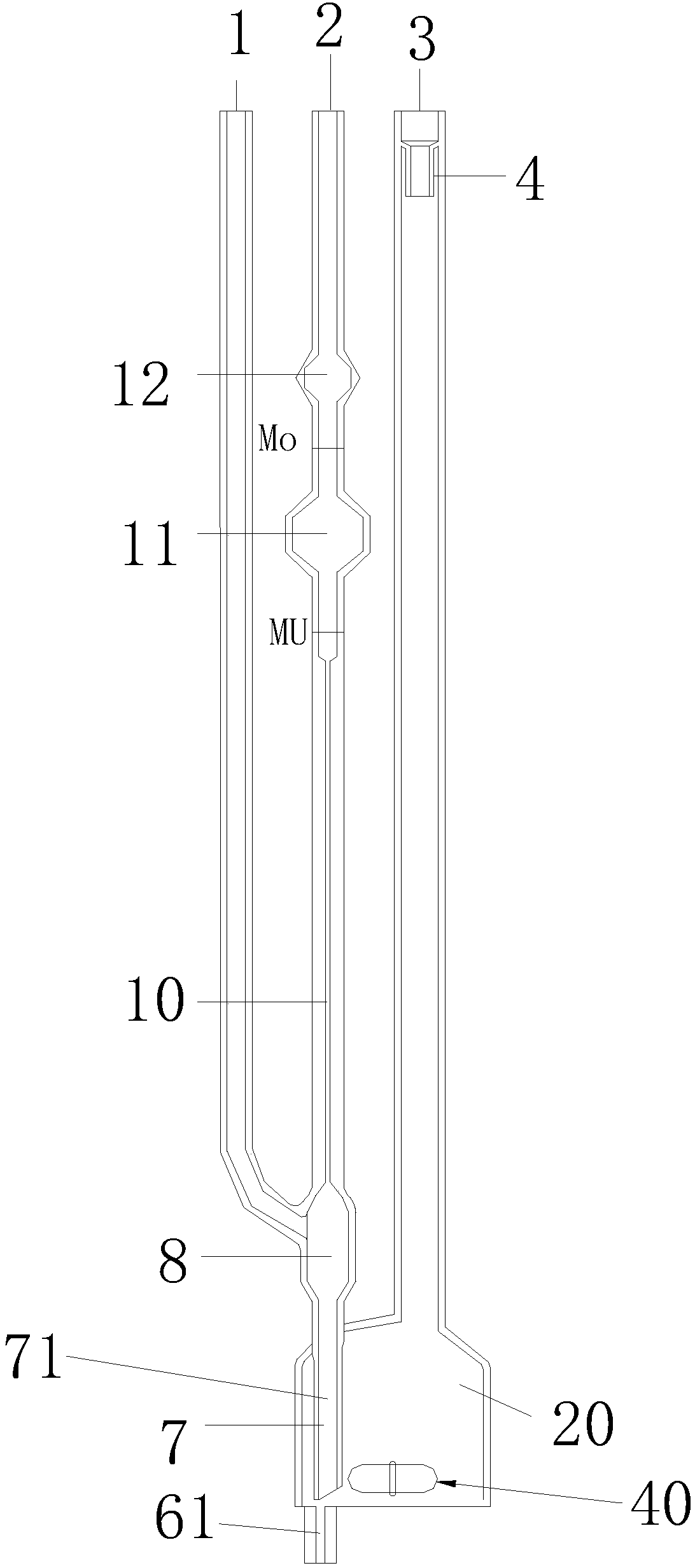

[0032] Such as figure 1 As shown, a diluted Ubbelohde viscometer includes a pumping liquid pipe 3 and a measuring pipe 2. One side of the measuring pipe 2 is connected with a vent pipe 1, and the lower end of the measuring pipe 2 is connected with a liquid inlet and discharge pipe 7. The bottom of the liquid pipe 3 is connected with a mixing ball 6 , the inlet and outlet pipe 7 is inserted into the bottom of the mixing ball 20 , and the lower end of the mixing ball 6 is connected with a raw liquid inlet pipe 61 . The bottom of the mixing ball 20 is a plane; the bottom of the cavity of the mixing ball 20 is provided with a magnetic stirrer 40 . A magnetic stirrer is provided on the outside of the corresponding mixing ball 20 to act on the magnetic stirrer 40 so that it can rotate and stir the mixed liquid. For easy understanding, the inlet and outlet pipe 7 is provided with an inlet and outlet channel 71 , and the inlet and outlet channel 71 is directly inserted into the botto...

Embodiment 2

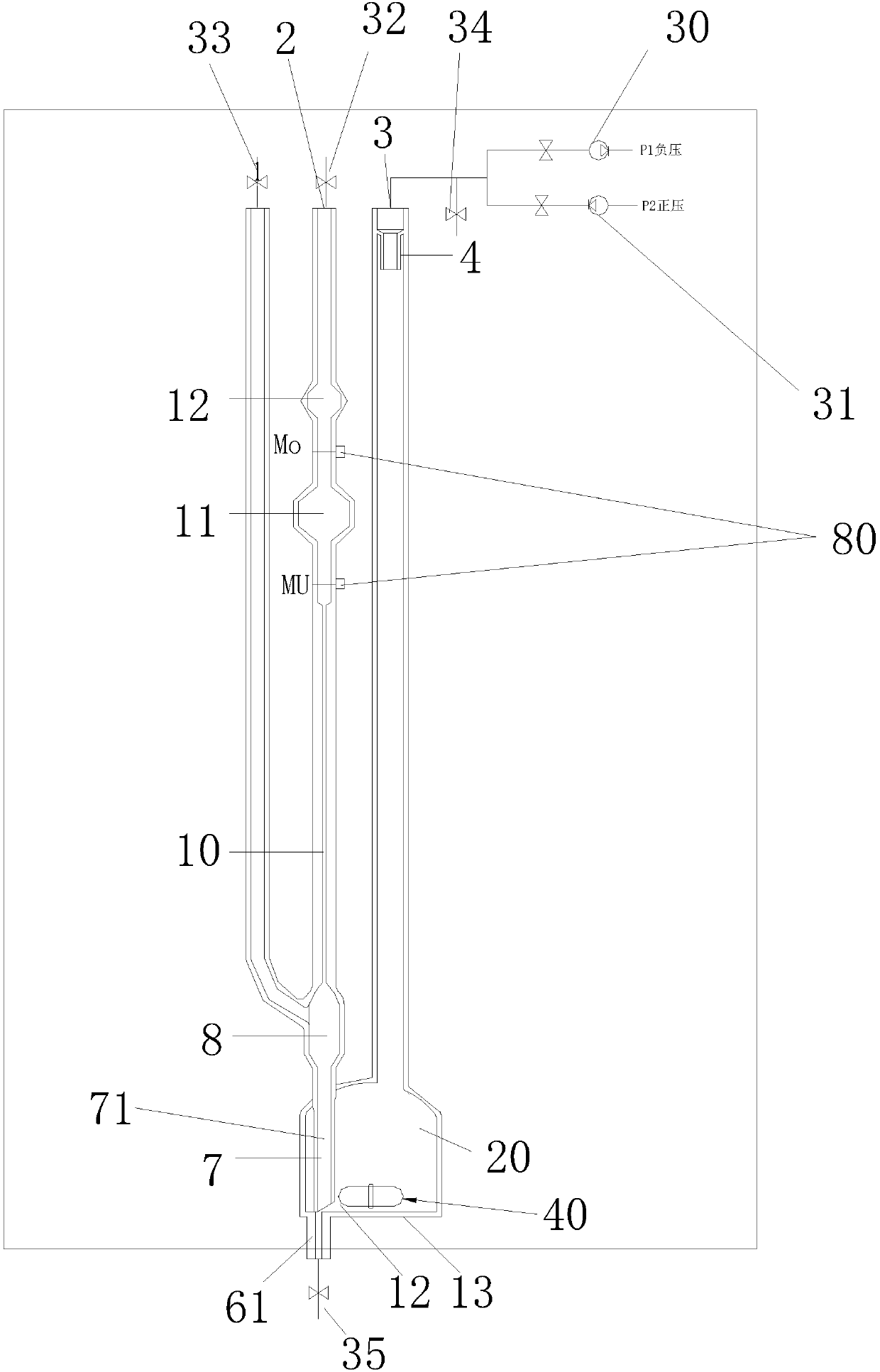

[0046] Such as figure 1 and figure 2 As shown, a fully automatic dilution viscometer includes the dilution Ubbelohde viscometer described in Example 1, the dilution Ubbelohde viscometer is arranged in an installation box 50, and the installation box 50 is a constant temperature box. The upper timing scale MO and the lower timing scale MU are provided with sensors, and in order to realize automation, the device also includes a controller. The first switch device 32, the second switch device 33, the third switch device 34 and the fourth switch device 35 are electromagnetic switch valves, which are connected with the controller line, and the liquid pumping device 30 and the liquid pushing device 31 are connected with the controller line; The liquid device 30 is a vacuum pump, and the liquid pushing device 31 is a booster pump.

[0047]The present invention also provides a measurement method utilizing the fully automatic dilution viscosity measuring device; comprising the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com