Motor Stator And Manufacturing Method

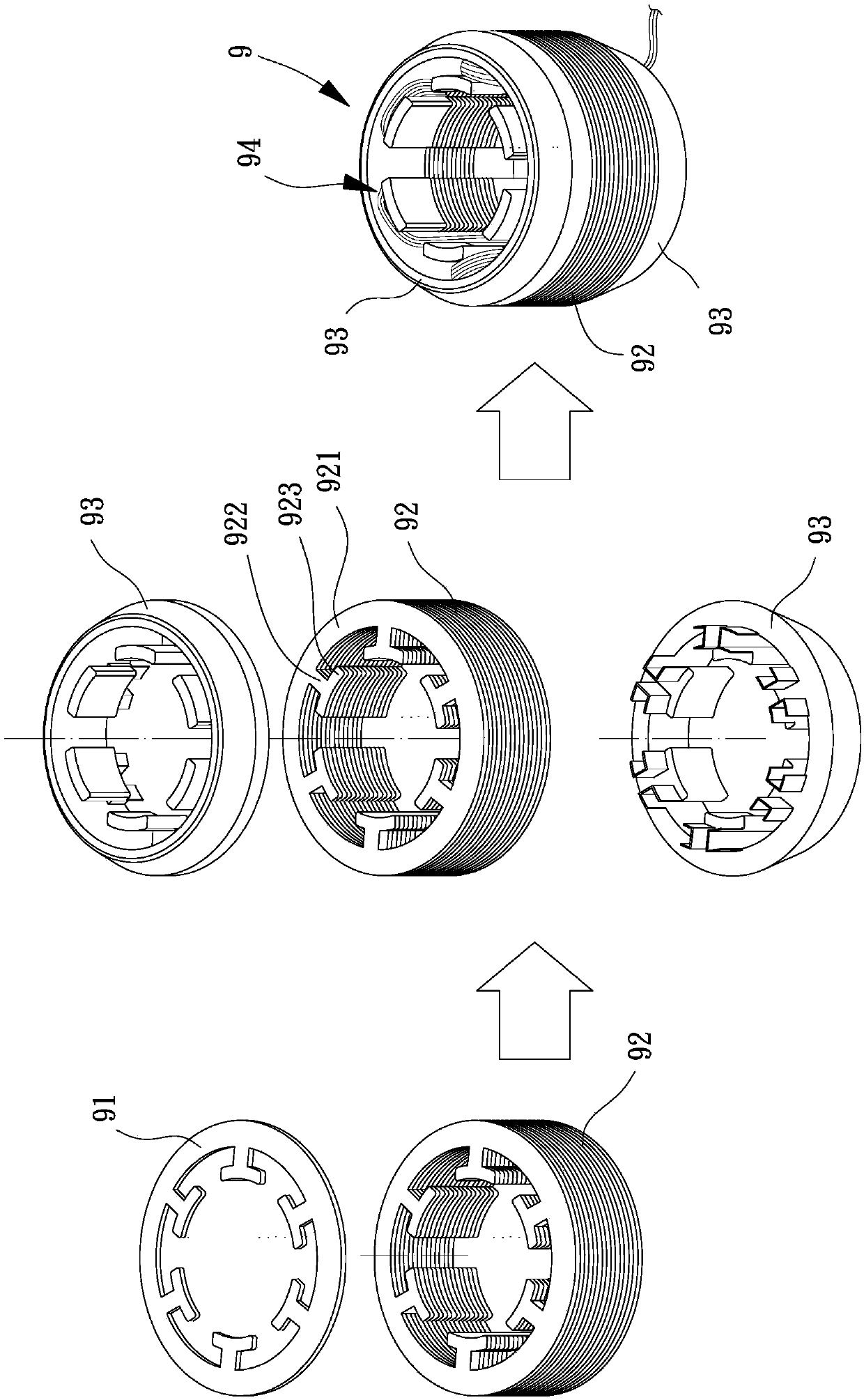

A technology of a motor stator and a manufacturing method, which is applied to the field of motor stator and its manufacturing, can solve the problems such as the inability to increase the number of teeth 922 of the stator iron core 92, the difficulty in increasing the torque and rotation speed of the motor, and the waste of material manufacturing costs, thereby achieving improved performance and Quality, reduce the difficulty of winding, reduce the effect of scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the following is based on the preferred embodiments of the present invention and is described in detail as follows in conjunction with the accompanying drawings:

[0069] An embodiment of the manufacturing method of the motor stator of the present invention includes the following steps:

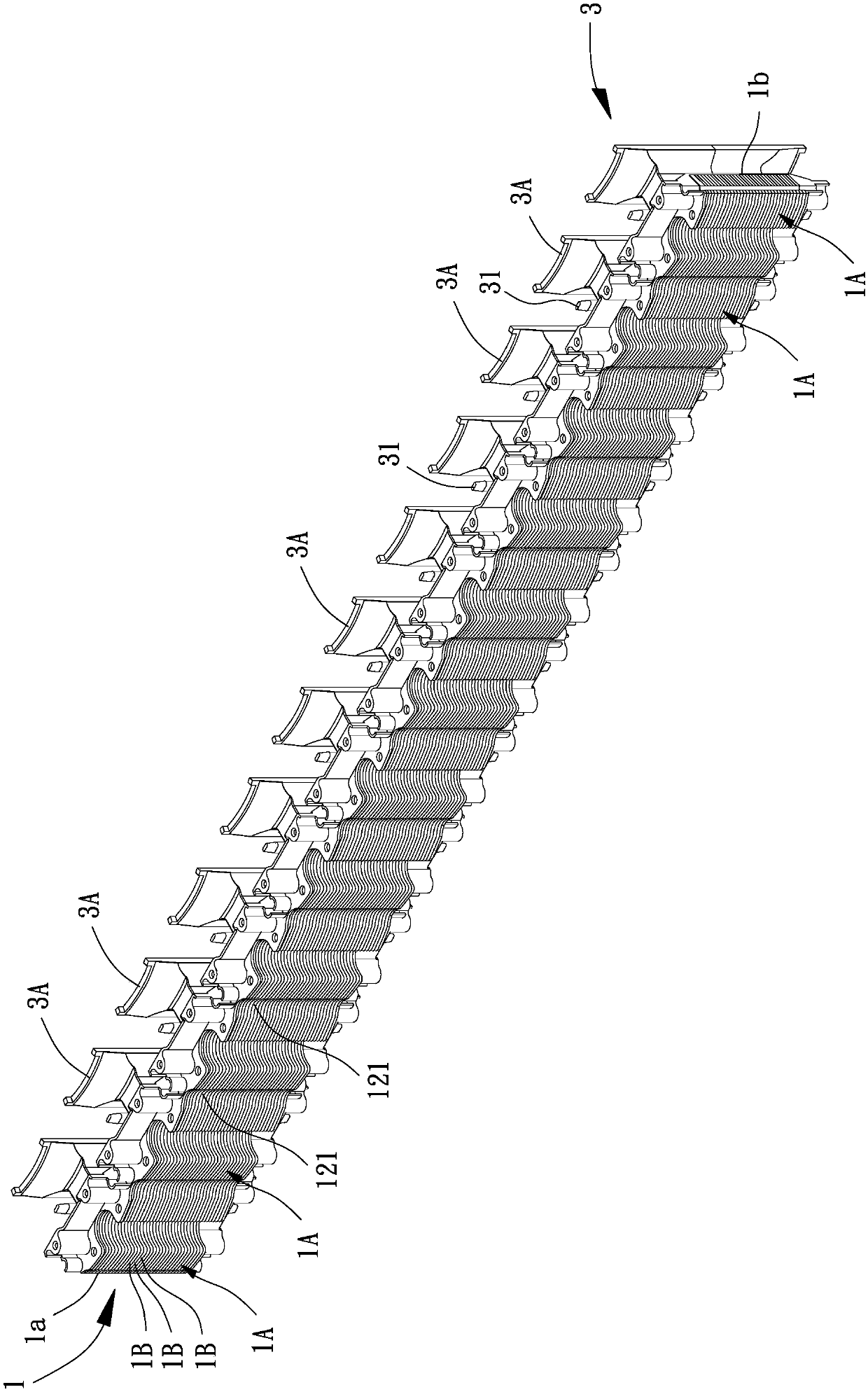

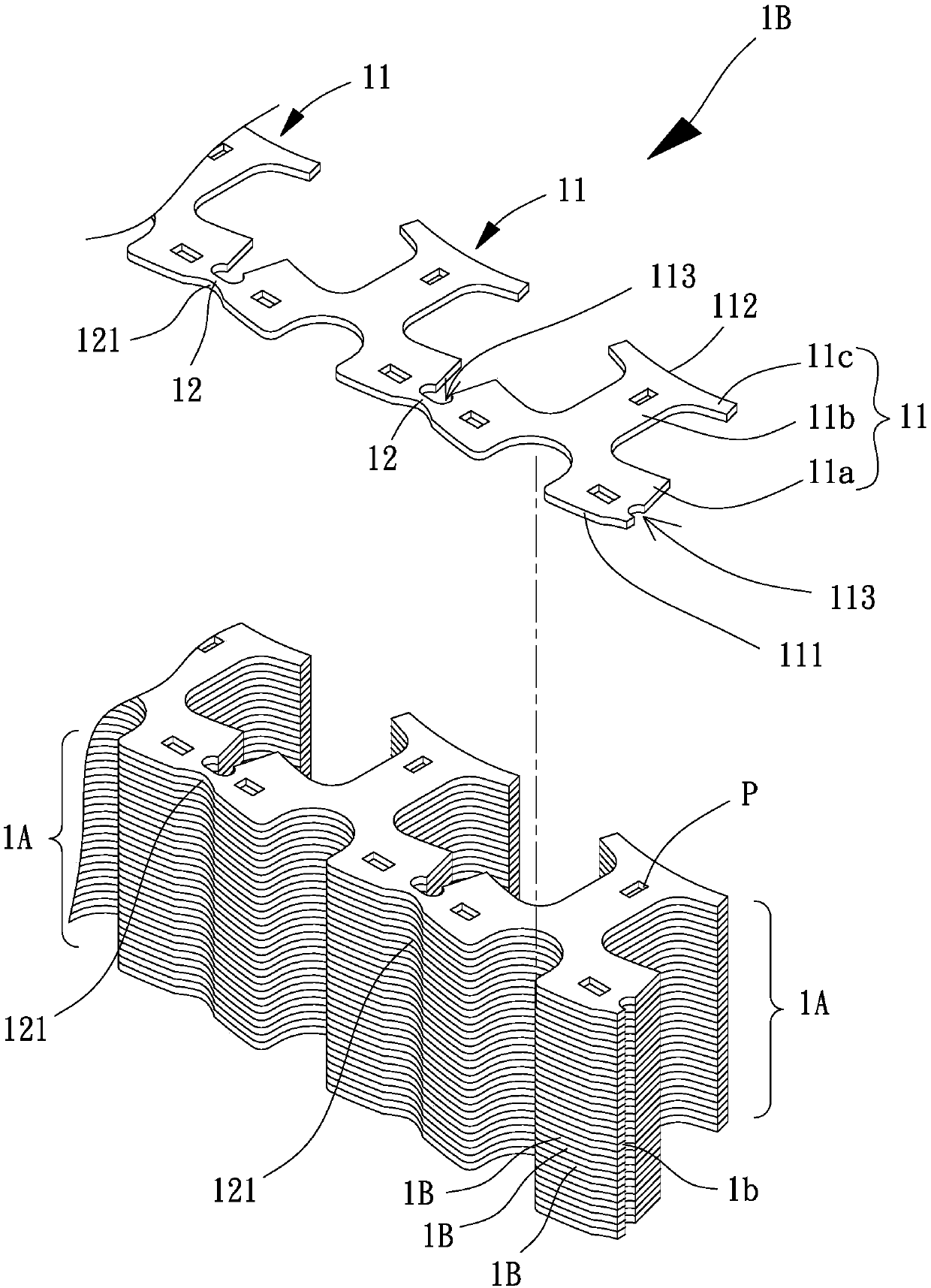

[0070] Please refer to figure 2 , 3 , provide an iron core bar 1, the iron core bar 1 has a plurality of iron core units 1A, and the plurality of iron core units 1A are connected to form a long strip, preferably a straight strip. In this embodiment, the iron core bar 1 can be stacked into a predetermined thickness by a plurality of silicon steel sheets 1B, and each silicon steel sheet 1B has a plurality of silicon steel sheet units 11 horizontally connected in a long series, and each silicon steel sheet unit 11 can be provided with A plurality of riveting poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com