Process for treating a gas contaminated by metals or organics compounds using a calcium-phosphate reactant comprising apatite

A calcium phosphate and reactant technology, applied in the field of gas contaminated by heavy metals or organic compounds, can solve the problems of expensive use and cost, and achieve the effect of improving fluidity and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0213] In this example, a calcium phosphate comprising 5% water and the remainder mainly comprising hydroxyapatite Ca5(PO4)3(OH), will be produced according to Example 8 of the WO2015 / 173437 patent application (according to the conditions of Example 1.b) The (Ca / P) reactants were tested in the laboratory and then in a small pilot plant using a portion of the industrial gas stream from the crematorium.

[0214] 1.a Preliminary laboratory tests

[0215] condition:

[0216] - Generates polluted gases from air

[0217] - Contaminants tested: Cd, Pb, Zn (introduced as chloride salts)

[0218] - in an oven at a temperature of 600°C to 700°C

[0219] - Use air flow at 150NL / h

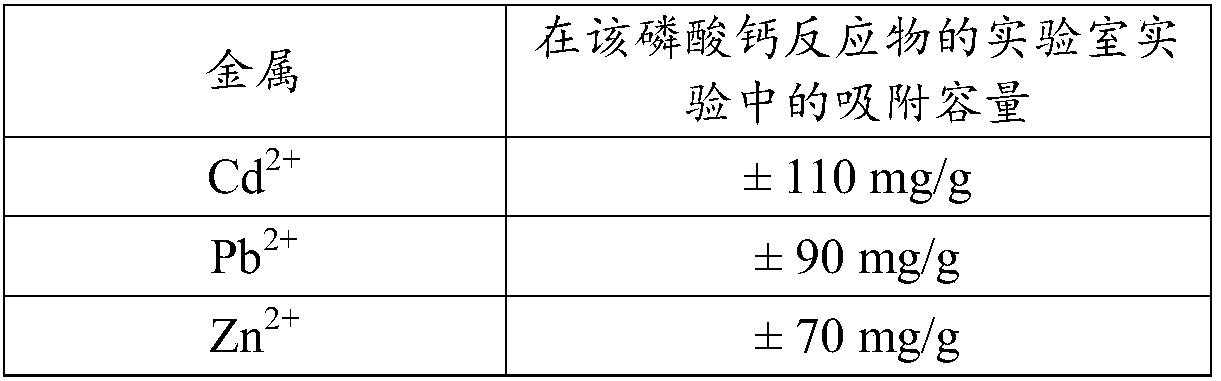

[0220] All 3 contaminants (Cd2+, Pb2+ and Zn2+) were unambiguously captured in one pass and showed excellent adsorption capacity when the gas stream was contacted with this calcium phosphate reactant (see Table 1).

[0221]

[0222] Table 1 Adsorption capacities of apatite-based calcium phosphate reactan...

example 2

[0255] Example 2 - Industrial Testing

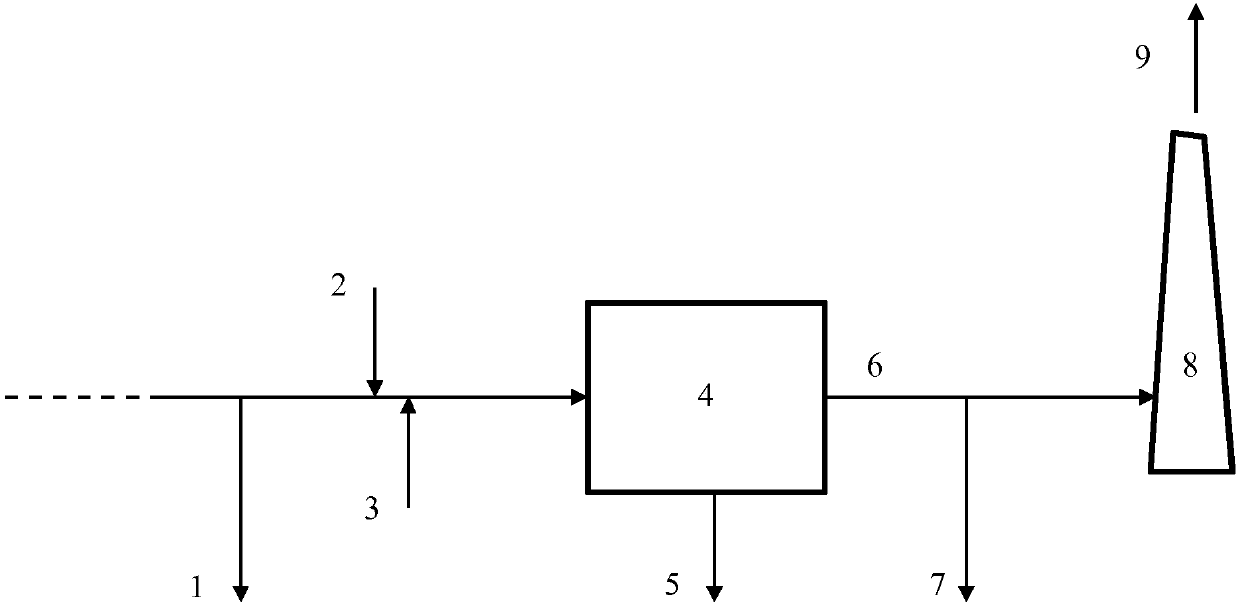

[0256] For industrial testing at the Uitzicht crematorium, according to figure 1 An industrial testing protocol using concomitant injection of sodium bicarbonate and apatite

[0257] The flue gas temperature when injecting apatite and sodium bicarbonate was 180°C.

[0258] Mercury and other metals are analyzed before the cyclone and in the chimney.

[0259] For industrial testing, regarding the location and arrangement of airflow sampling and metal analysis:

[0260] - Same as the first test, using glass fiber filter

[0261] -and then the chimney, with a glass fiber filter before bubbling the sampled airflow.

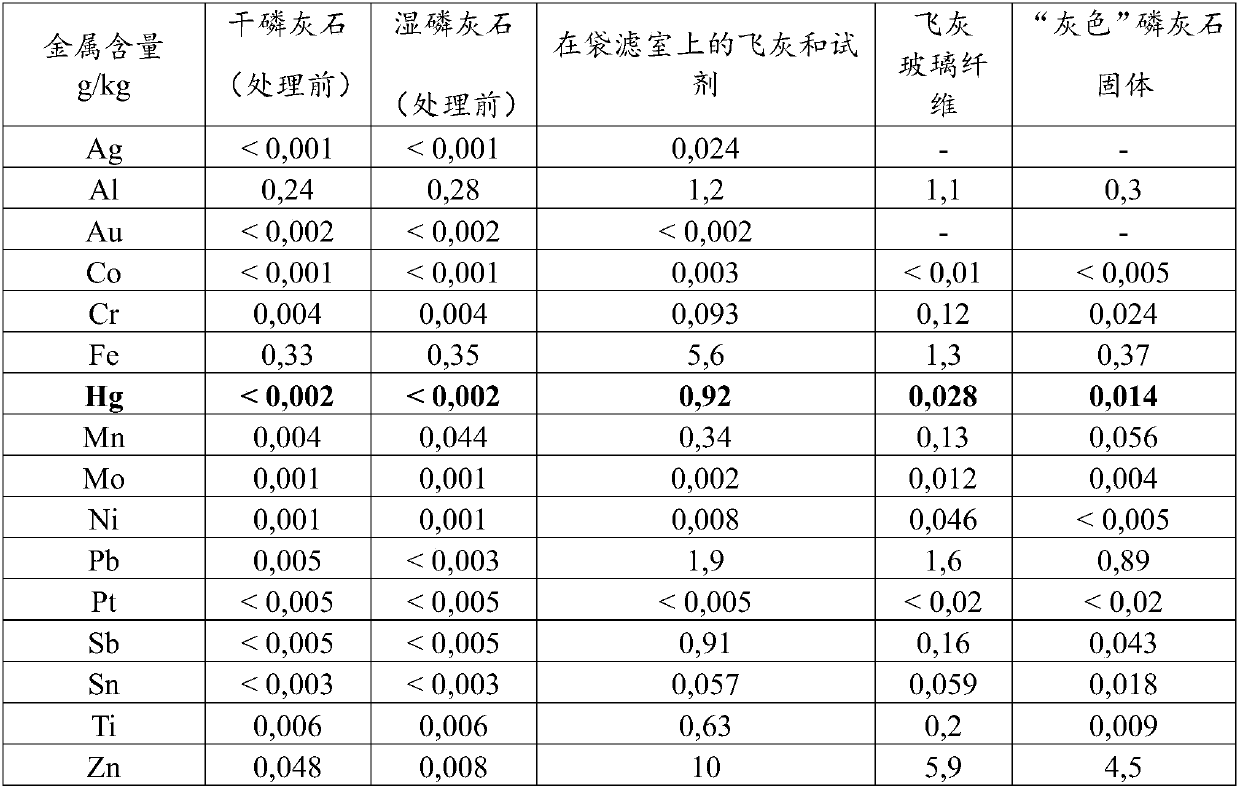

[0262] The results of the industrial tests are given in Table 3 and in the comments below:

[0263] - Regarding metal analysis in airflow:

[0264] no Hg in the Hg trap from the quench and chimney (dichromate solution = Hg trap),

[0265] Very low concentrations in the filtered gas solution,

[0266] levels in the flue ga...

example 3

[0271] Example 3 - Industrial Testing

[0272] Industrial tests are carried out in a domestic waste incinerator with a capacity of 11t / h. The airflow to be treated is 63000Nm3 / h. The treatment line is equipped with dry mitigation injection of alkaline compounds, capable of injecting sodium bicarbonate or slaked lime for acid gas mitigation (HCl, HF, SO2, SO3), as well as for heavy metals, dioxins and furans and aromatic organics Activated carbon sorbent injection (including benzo(a)pyrene). The average HCl concentration in the gas stream was about 1100 mg / Nm3 (at 11% O2) and the average SOx concentration was about 205 mg / Nm3. The temperature of the gas at the injection point was about 230°C. The average sodium bicarbonate injection flow reported per ton of waste was about 14.8 kg / t waste and the activated carbon injection flow was about 0.4 kg / t waste. The contact time of the basic compound and adsorbent (related to the length of the flue gas duct up to the downstream filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com