Rolling stand for the rolling of rolling stock

A technology for rolling mill stands and rolled materials, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., which can solve the problems of long low-pressure pipelines and achieve cost saving and good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention is explained in detail below by way of example with reference to the mentioned drawings. In all figures, the same technical elements are identified with the same reference numerals. The reference number 140 is also representatively used for all variants of the reference number, i.e., representing 140', 140", 140-1, 140-2, 140-I, 140-II, 140-III and 140-IV A similar situation applies for reference numeral 130 .

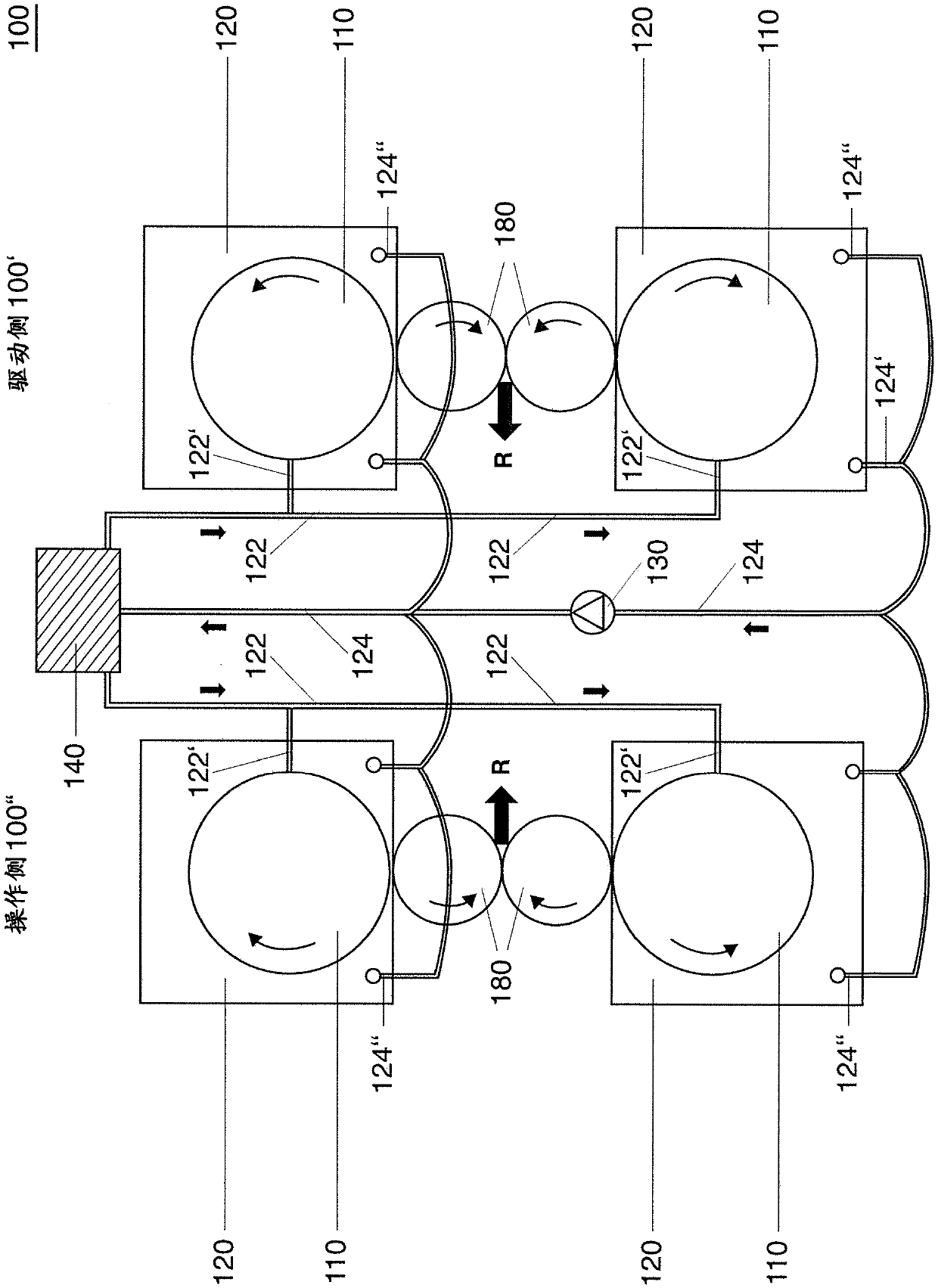

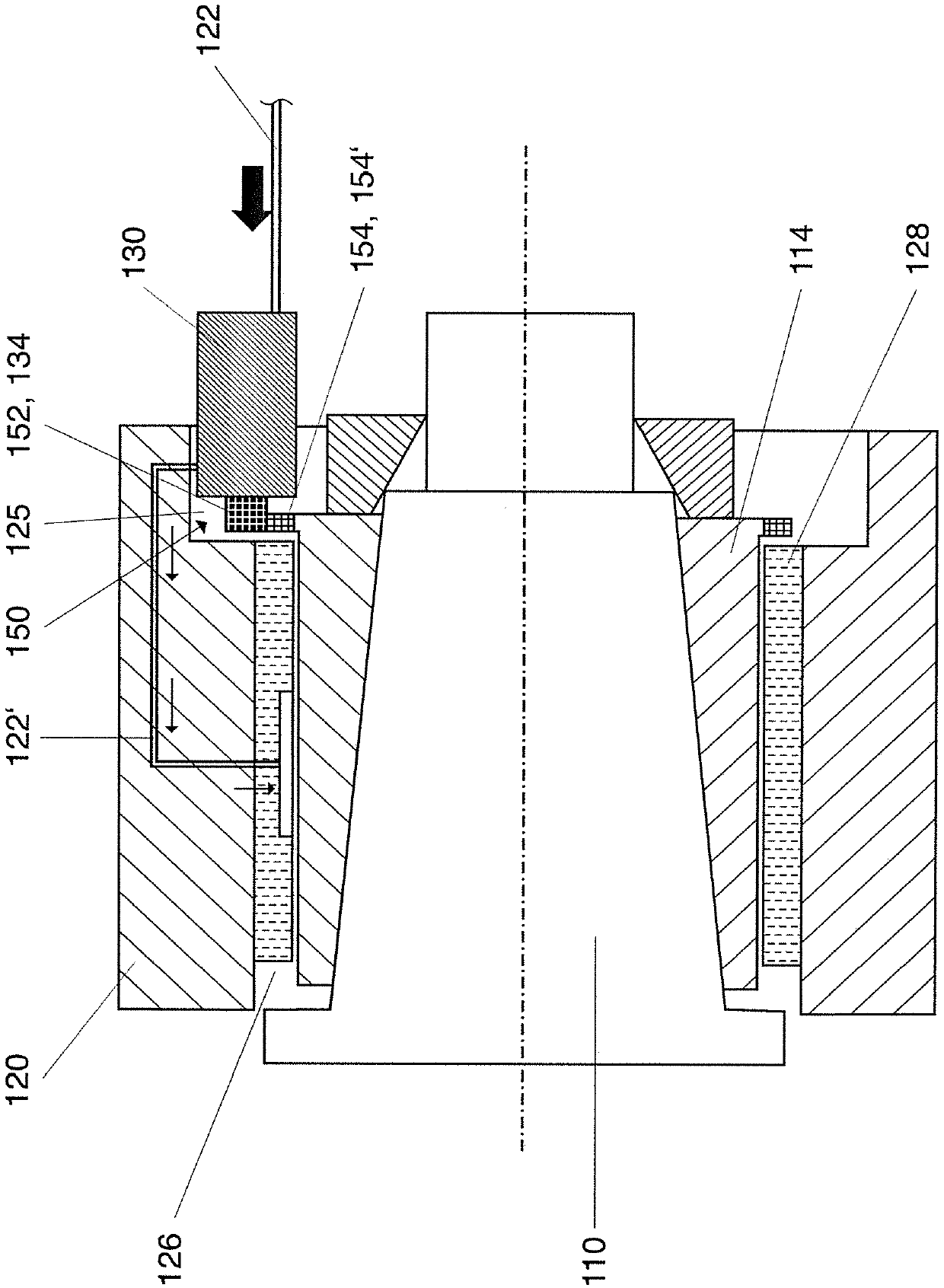

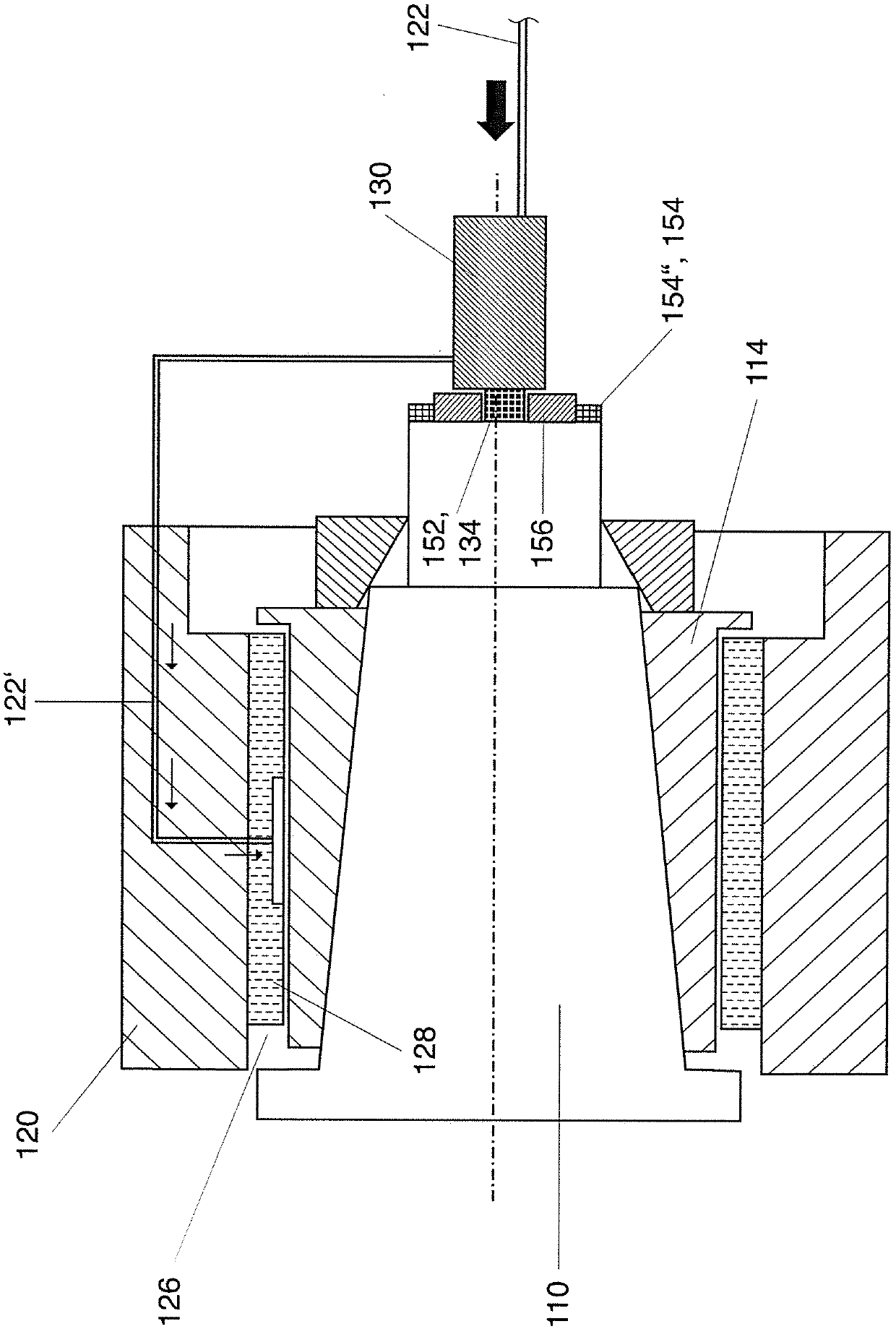

[0034] all attached figure 1 and 4 Figures 7 to 7 show four-high rolling stands 100 as examples, which respectively have a roll stand 100' on the drive side and a roll stand 100" on the operating side. Each roll stand has two supporting rollers, which are arranged in The four roll necks 110 are respectively rotatably supported in oil film bearings 120. Each oil film bearing 120 has a low-pressure input pipeline 122 and a low-pressure discharge pipeline 124. The return part is led back to one or more tanks 140; The inlet is supplied by the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com