Punch tool system

A punching and tooling technology, applied in the field of punching tool system, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

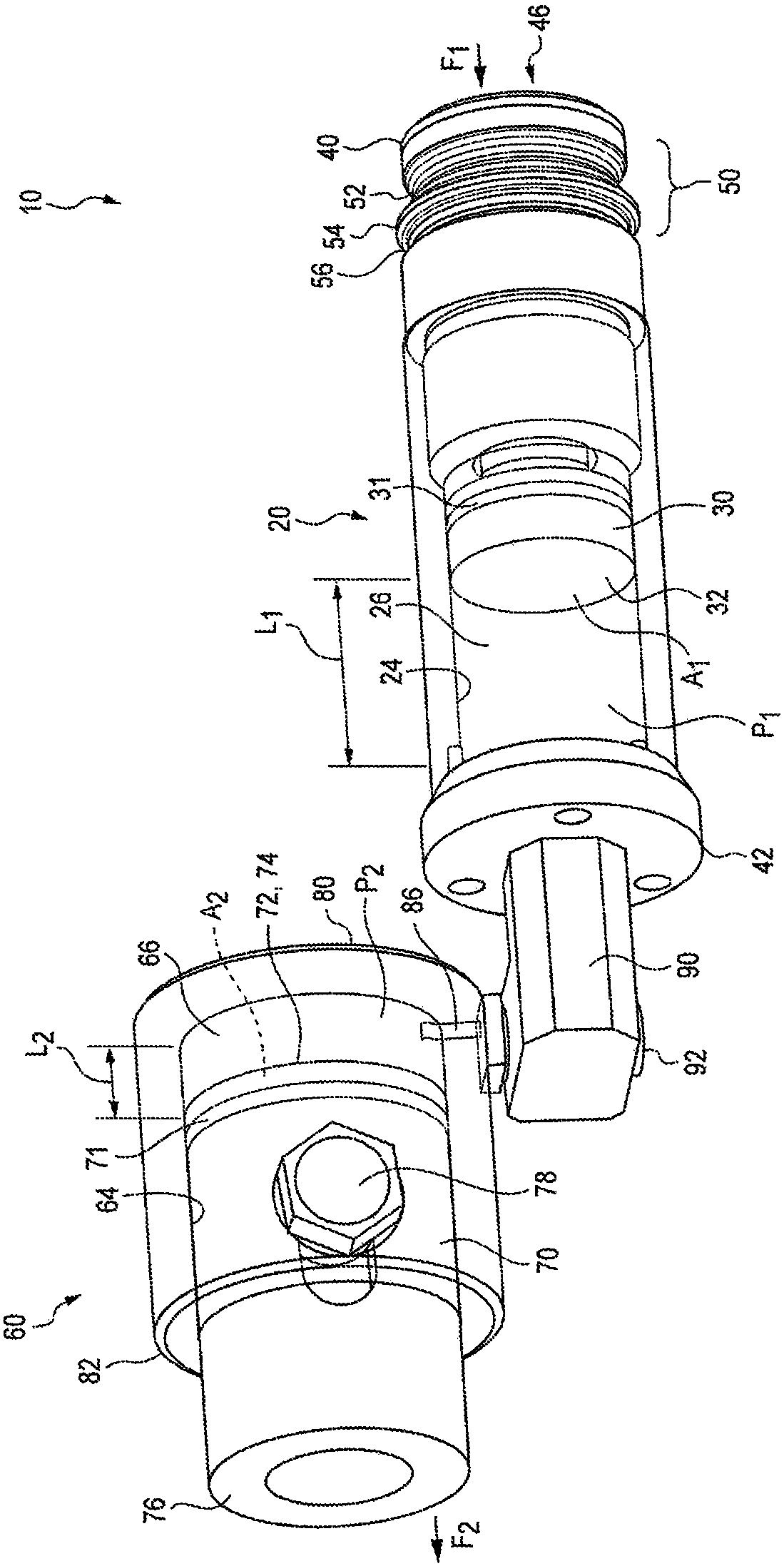

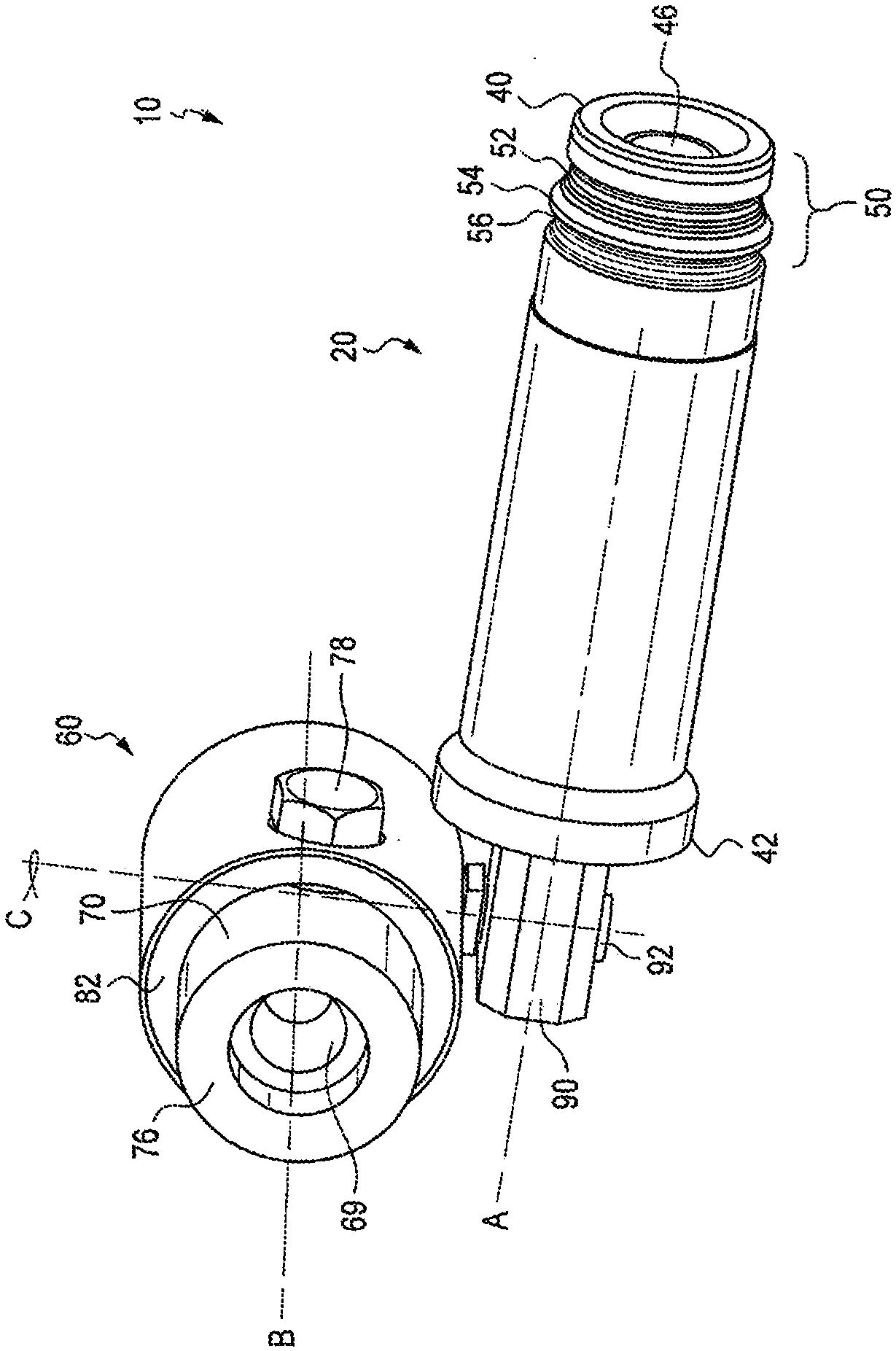

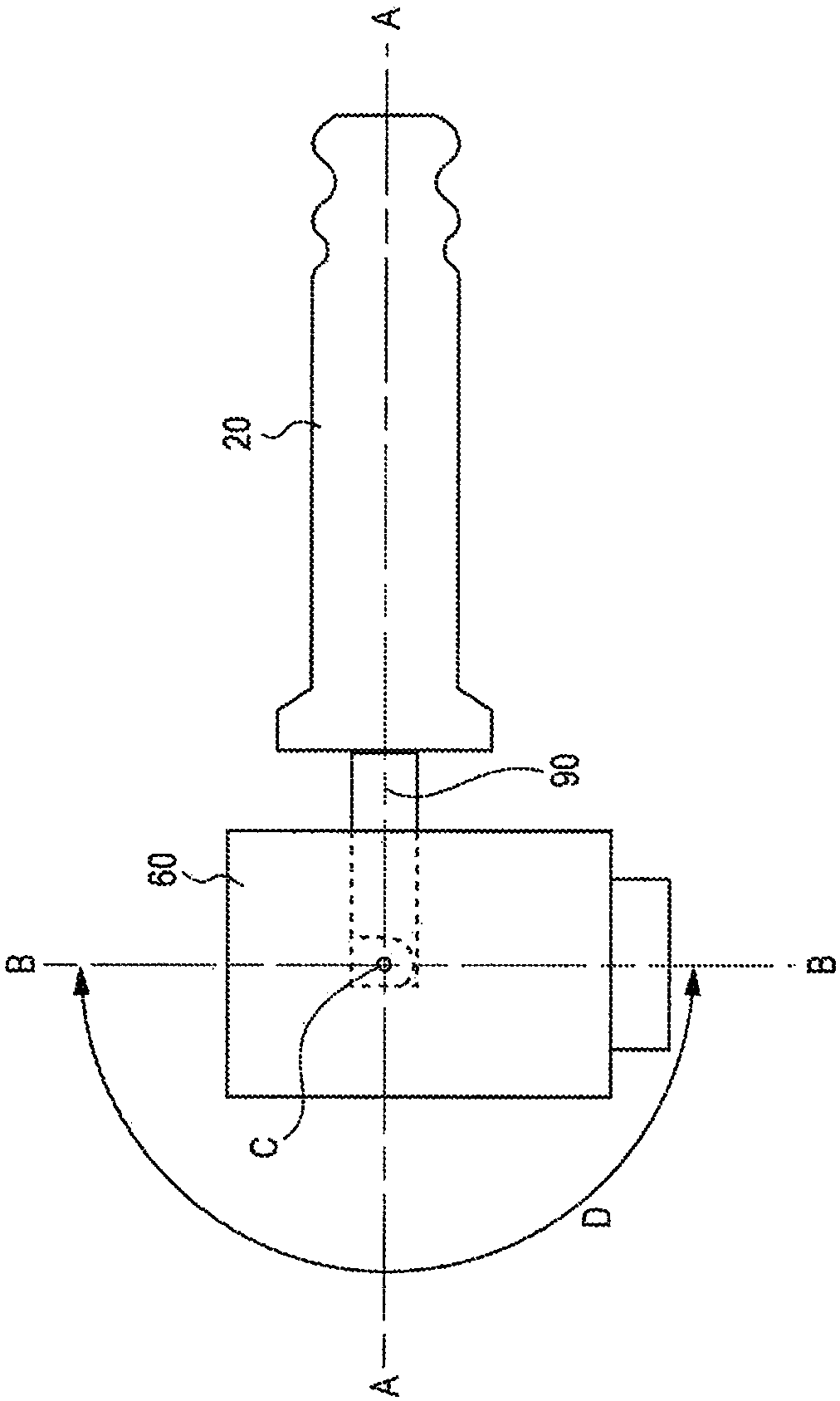

[0023] The subject matter relates to non-powered punching tools for forming holes or bores in workpieces such as sheet metal. The piercing tool includes a master cylinder having a linearly moveable plunger disposed within a chamber defined within the master cylinder, and a slave cylinder having a linearly moveable plunger disposed within a chamber defined within the slave cylinder . The slave cylinder is movable relative to the master cylinder. The chamber of the master cylinder is in hydraulic communication with the chamber of the slave cylinder such that linear displacement of either plunger results in a corresponding linear displacement of the other plunger. The master cylinder may be releasably engageable with a punch tool or other device that provides powered extension of a plunger or other member. The plunger or member of the punching tool displaces the plunger of the master cylinder by extending, thereby causing the displacement of the plunger of the slave cylinder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com