Movable type screw locking tool

A screw locking and mobile technology, which is applied in the field of mobile screw locking tooling, can solve the problems of many operators, high labor costs, and high technical requirements for operators, and achieve the effects of ensuring product quality, saving labor costs, and high operating accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

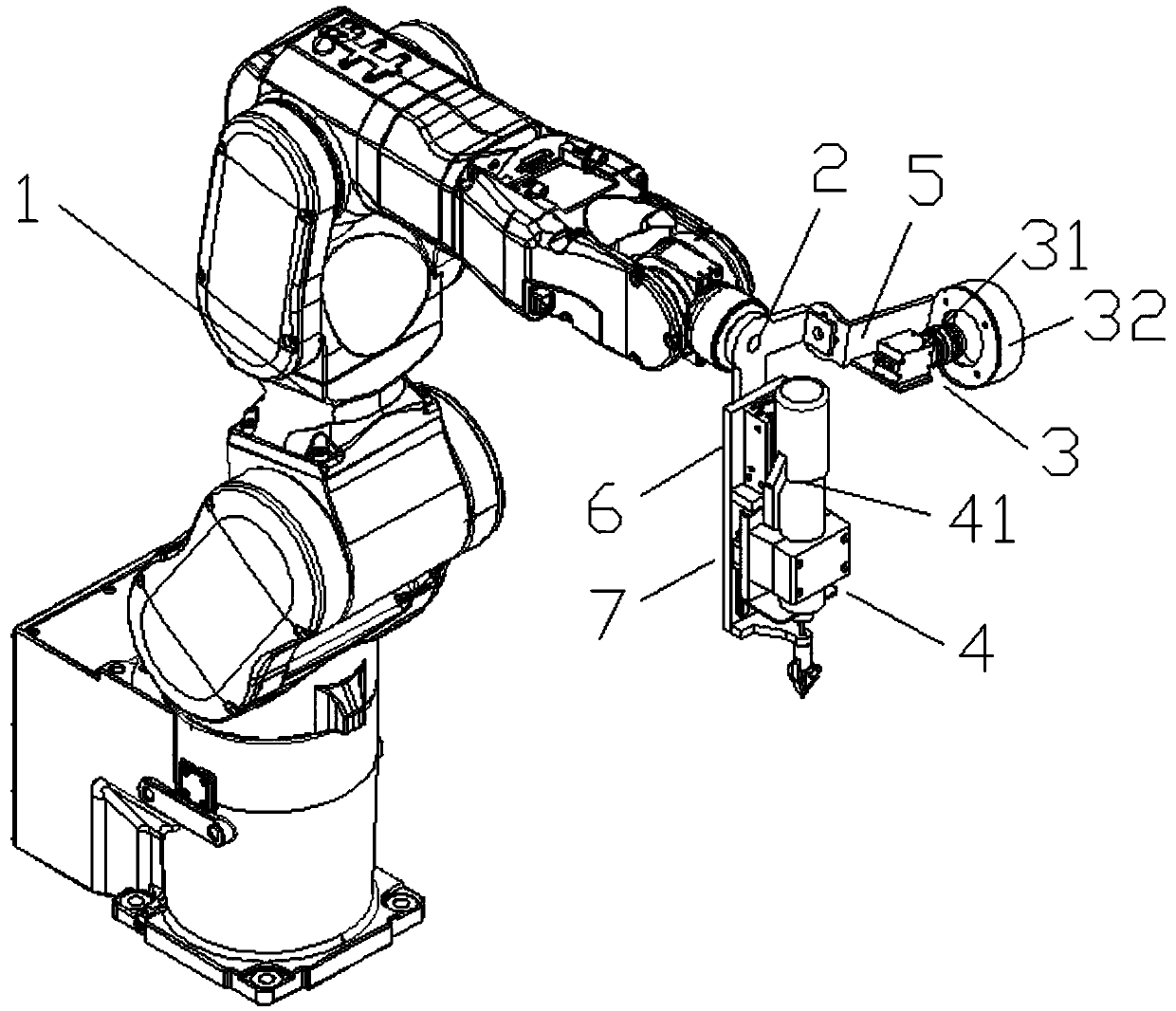

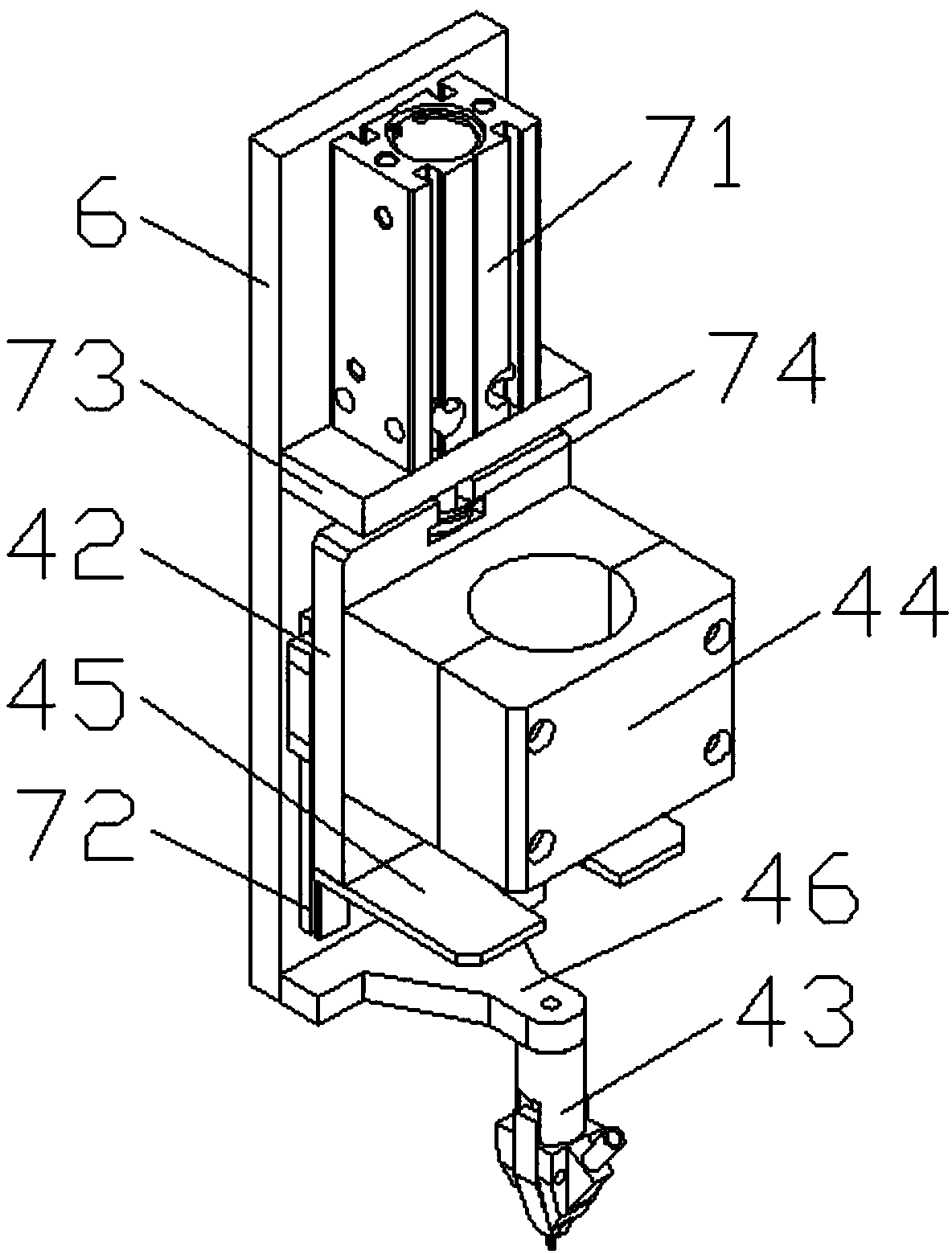

[0014] Such as figure 1 , figure 2 As shown, a mobile locking screw tooling includes a mechanical arm 1, a bracket 2 installed on the end of the mechanical arm 1, a positioning mechanism 3 and a locking screw mechanism 4 fixed on the bracket 2, the positioning mechanism 3 and the locking screw mechanism 4 is installed at a certain angle on the bracket 2. The positioning mechanism 3 is used to scan the workpiece and determine the position of the screw hole. The locking screw mechanism 4 is used to introduce and tighten the screws. The positioning mechanism 3 is fixed to the bracket 2 through the positioning plate 5. The positioning mechanism 3 Including a camera 31 and a light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com