A production process of double-sided curb stone

A production process and technology of curb stones, applied in the direction of gutters/curb stones, roads, roads, etc., can solve the problems of unsightly curb stones, difficulty in producing double-sided curb stones, reducing the service life of curb stones, etc., and achieve market benefits Improvement, ingenious design, and the effect of enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

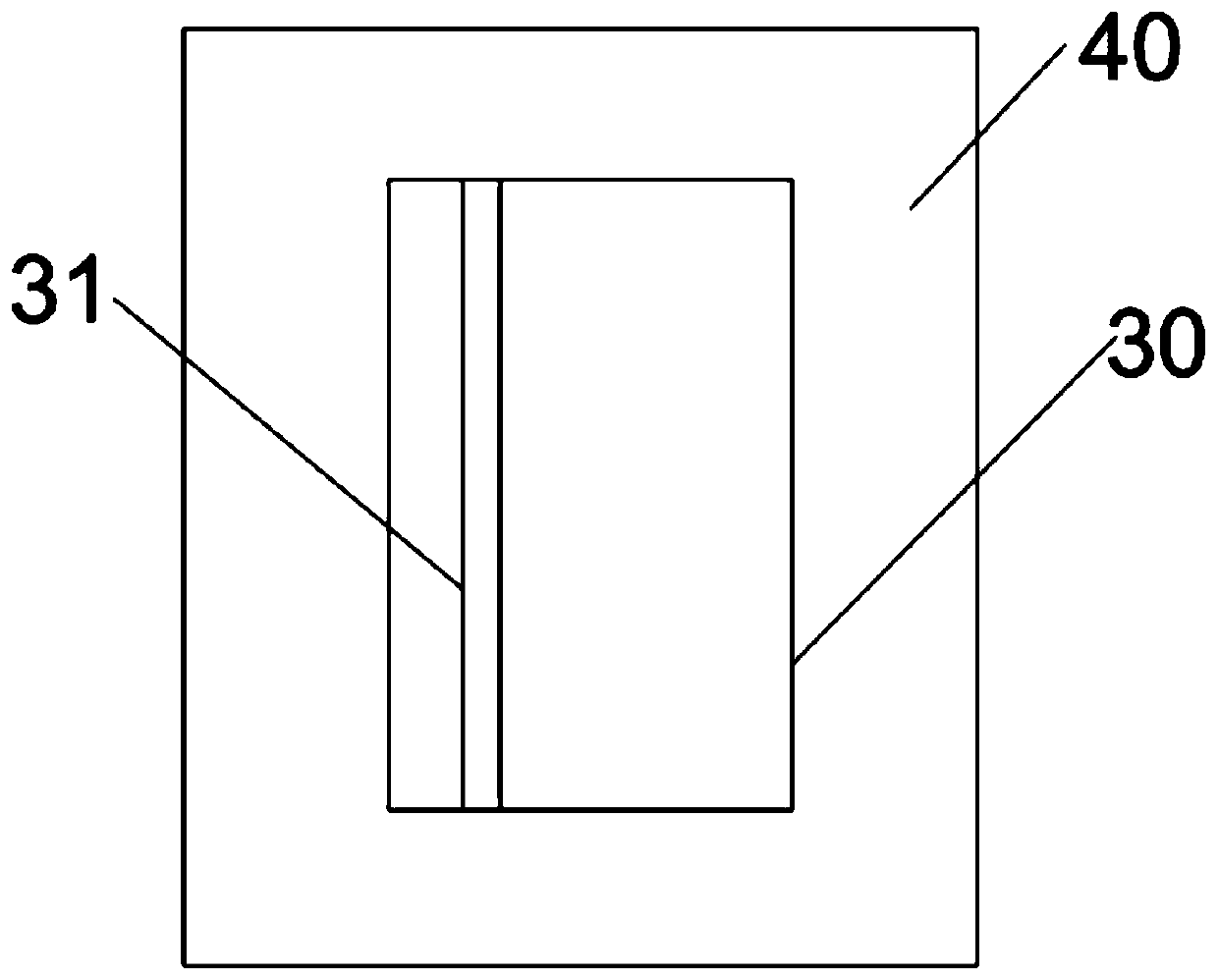

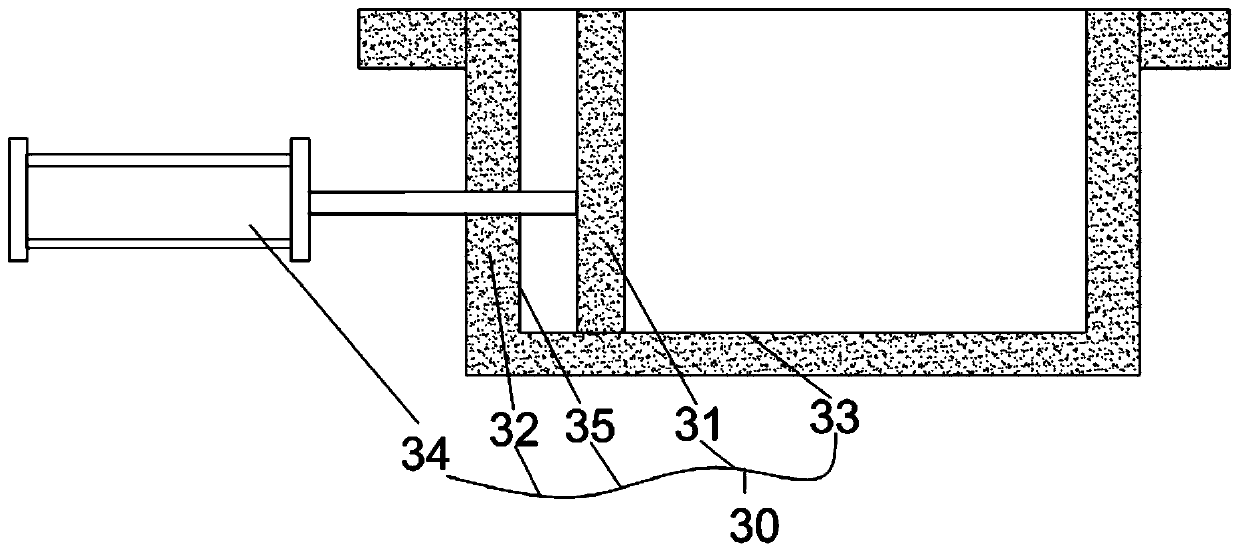

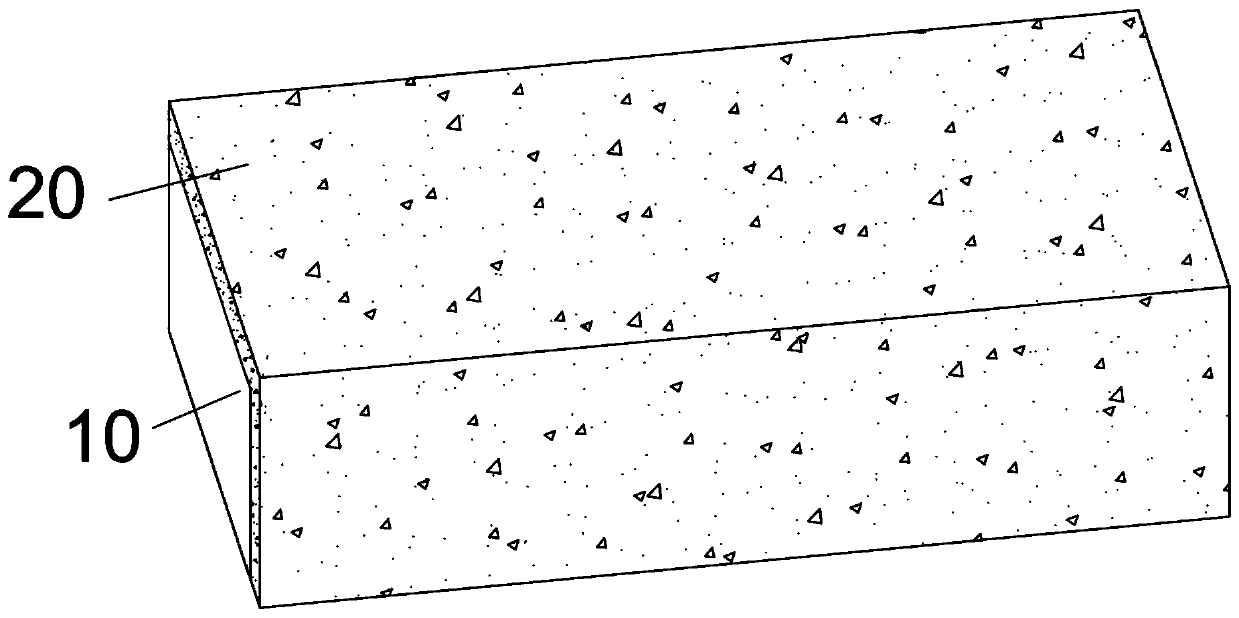

[0033] A double-sided curbstone production process, the double-sided curbstone includes a base block 10 and a surface layer block 20, the surface layer block 20 mainly includes two parts, one part is placed above the base layer block 10, and the other part is placed on the top of the base layer block 10 On the side of the base block 10, the base block 10 is filled with a base material, and the surface block 20 is filled with a surface material. The base material is mainly composed of cement, rice stone, and crushed powder. The composition of the surface material is mainly composed of white natural sand, black natural sand and white cement. The mold frame 30 mainly includes a bottom plate 33, which is installed on the vibration excitation platform 40, and a frame is arranged above the bottom plate 33. body 32;

[0034] The specific process steps for preparing double-sided curb stone are as follows:

[0035] S1: Place the mold frame 30 on the vibration excitation platform 40, t...

Embodiment 2

[0041] A double-sided curbstone production process, the double-sided curbstone includes a base block 10 and a surface layer block 20, the surface layer block 20 mainly includes two parts, one part is placed above the base layer block 10, and the other part is placed on the top of the base layer block 10 On the side of the base block 10, the base block 10 is filled with a base material, and the surface block 20 is filled with a surface material. The base material is mainly composed of cement, rice stone, and crushed powder. The composition of the surface material is mainly composed of white natural sand, black natural sand and white cement. The mold frame 30 mainly includes a bottom plate 33, which is installed on the vibration excitation platform 40, and a frame is arranged above the bottom plate 33. body 32;

[0042] The specific process steps for preparing double-sided curb stone are as follows:

[0043] S1: Place the mold frame 30 on the vibration excitation platform 40, the...

Embodiment 3

[0049] A double-sided curbstone production process, the double-sided curbstone includes a base block 10 and a surface layer block 20, the surface layer block 20 mainly includes two parts, one part is placed above the base layer block 10, and the other part is placed on the top of the base layer block 10 On the side of the base block 10, the base block 10 is filled with a base material, and the surface block 20 is filled with a surface material. The base material is mainly composed of cement, rice stone, and crushed powder. The composition of the surface material is mainly composed of white natural sand, black natural sand and white cement. The mold frame 30 mainly includes a bottom plate 33, which is installed on the vibration excitation platform 40, and a frame is arranged above the bottom plate 33. body 32;

[0050] The specific process steps for preparing double-sided curb stone are as follows:

[0051] S1: Place the mold frame 30 on the vibration excitation platform 40, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com