A kind of inspection and sealing control method of spherical valve

A control method and maintenance seal technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problems of difficult to realize the maintenance seal throwing and retracting freely, unable to ensure that the maintenance seal is not opened, etc., to improve the maintenance safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

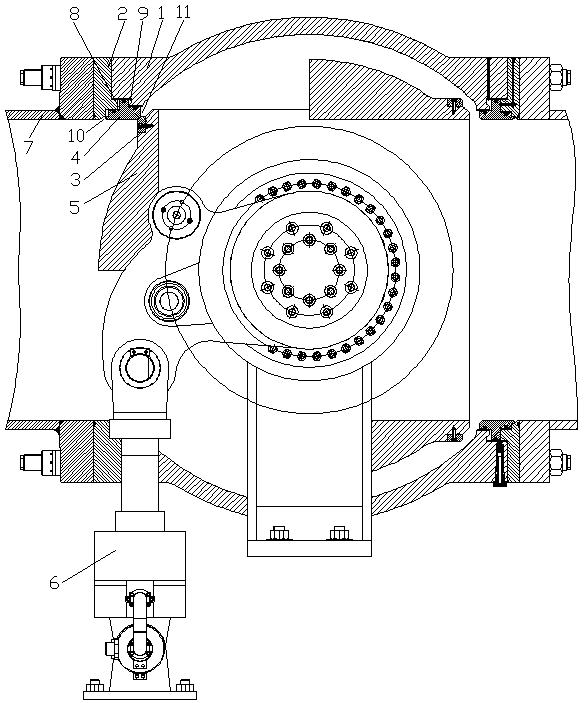

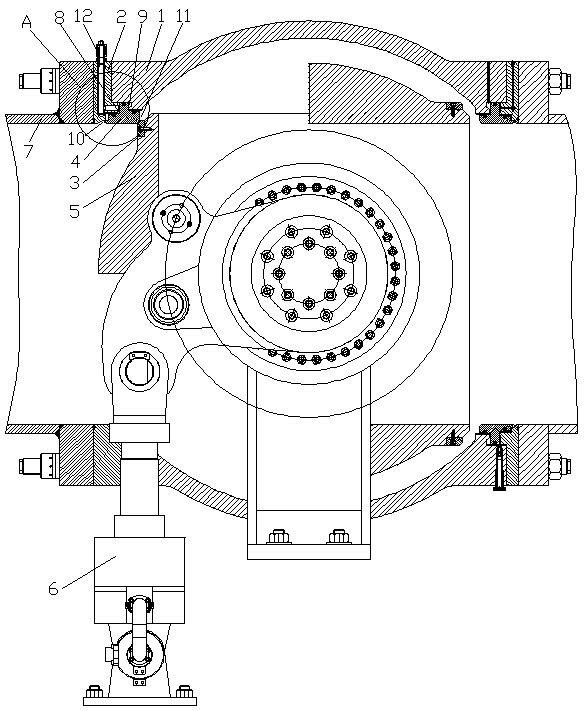

[0047] A method for overhauling and sealing a spherical valve comprises the following steps:

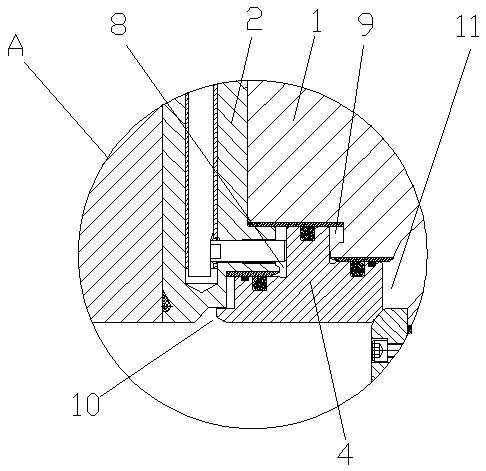

[0048] a. Set the area of the opening chamber 9 of the movable sealing ring 4 in the spherical valve, the area of the upstream high pressure chamber 10, the area of the upstream input chamber 8 and the area of the downstream pressure chamber 11. The area of the upstream high pressure chamber 10 is larger than the area of the opening chamber 9 and the area of the upstream input chamber 8 is greater than the area of the open chamber 9, and the sum of the area of the open chamber 9 and the area of the downstream pressure chamber 11 which is 0.7 times greater than the area of the upstream high pressure chamber 10;

[0049] b. For normal maintenance, when the turbine is shut down, the valve 5 of the spherical valve is fully closed through the servomotor 6, and the movable sealing ring 4 is put into the water, and the water in the downstream pipeline of the spherical v...

Embodiment 2

[0054] A method for overhauling and sealing a spherical valve comprises the following steps:

[0055] a. Set the area of the opening chamber 9 of the movable sealing ring 4 in the spherical valve, the area of the upstream high pressure chamber 10, the area of the upstream input chamber 8 and the area of the downstream pressure chamber 11. The area of the upstream high pressure chamber 10 is larger than the area of the opening chamber 9 and the area of the upstream input chamber 8 is greater than the area of the open chamber 9, and the sum of the area of the open chamber 9 and the area of the downstream pressure chamber 11 which is 0.7 times greater than the area of the upstream high pressure chamber 10;

[0056] b. For normal maintenance, when the turbine is shut down, the valve 5 of the spherical valve is fully closed through the servomotor 6, and the movable sealing ring 4 is put into the water, and the water in the downstream pipeline of the spherical v...

Embodiment 3

[0062] A method for overhauling and sealing a spherical valve comprises the following steps:

[0063] a. Set the area of the opening chamber 9 of the movable sealing ring 4 in the spherical valve, the area of the upstream high pressure chamber 10, the area of the upstream input chamber 8 and the area of the downstream pressure chamber 11. The area of the upstream high pressure chamber 10 is larger than the area of the opening chamber 9 and the area of the upstream input chamber 8 is greater than the area of the open chamber 9, and the sum of the area of the open chamber 9 and the area of the downstream pressure chamber 11 which is 0.7 times greater than the area of the upstream high pressure chamber 10;

[0064] b. For normal maintenance, when the turbine is shut down, the valve 5 of the spherical valve is fully closed through the servomotor 6, and the movable sealing ring 4 is put into the water, and the water in the downstream pipeline of the spherical v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com