Lamp

A lamp and lampshade technology, which is applied in the field of lamps using semiconductor light-emitting components, can solve the problems of poor heat dissipation, environmental protection, and affecting the service life of lamps, etc., achieve good waterproof effect, and improve the effect of optical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

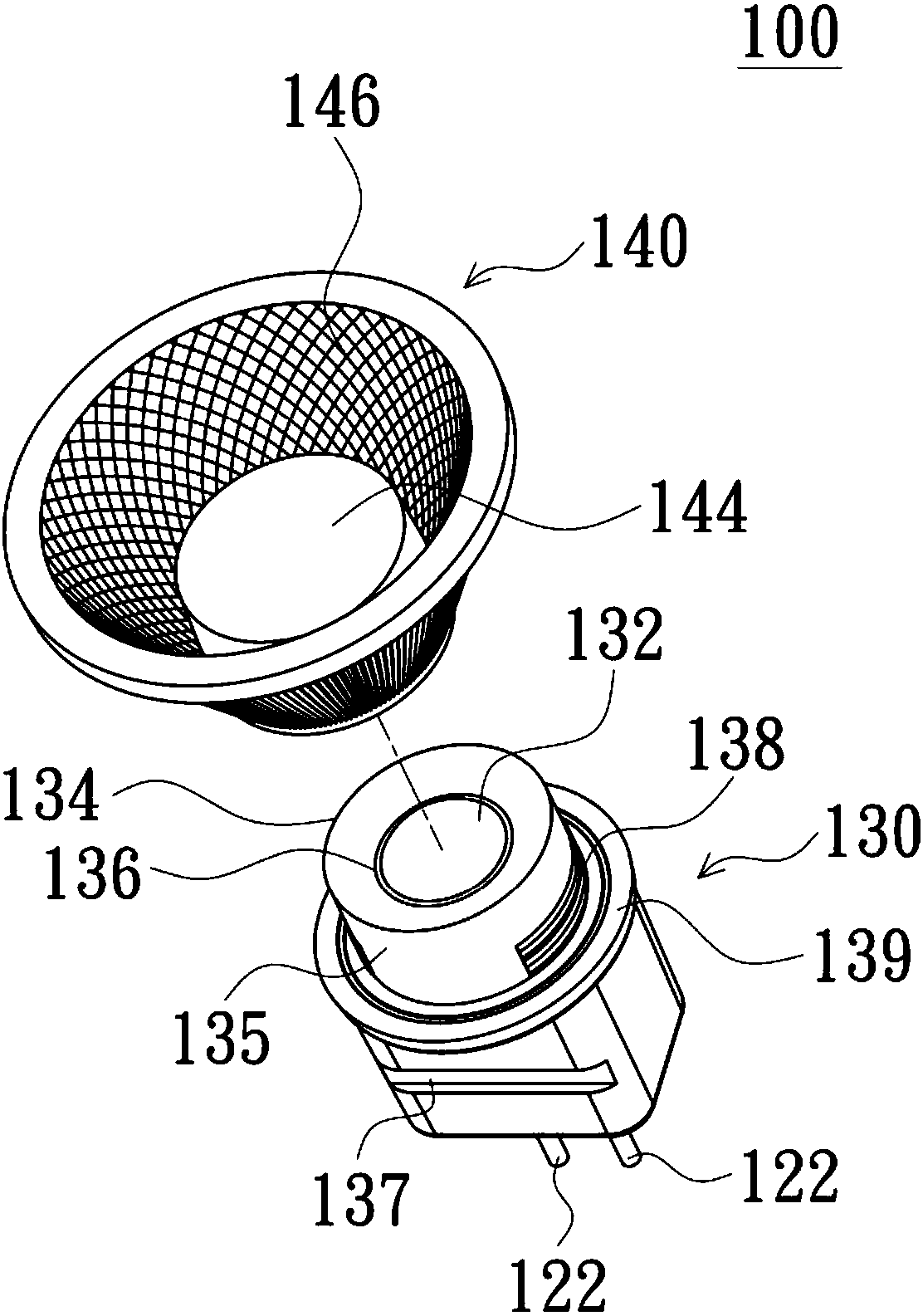

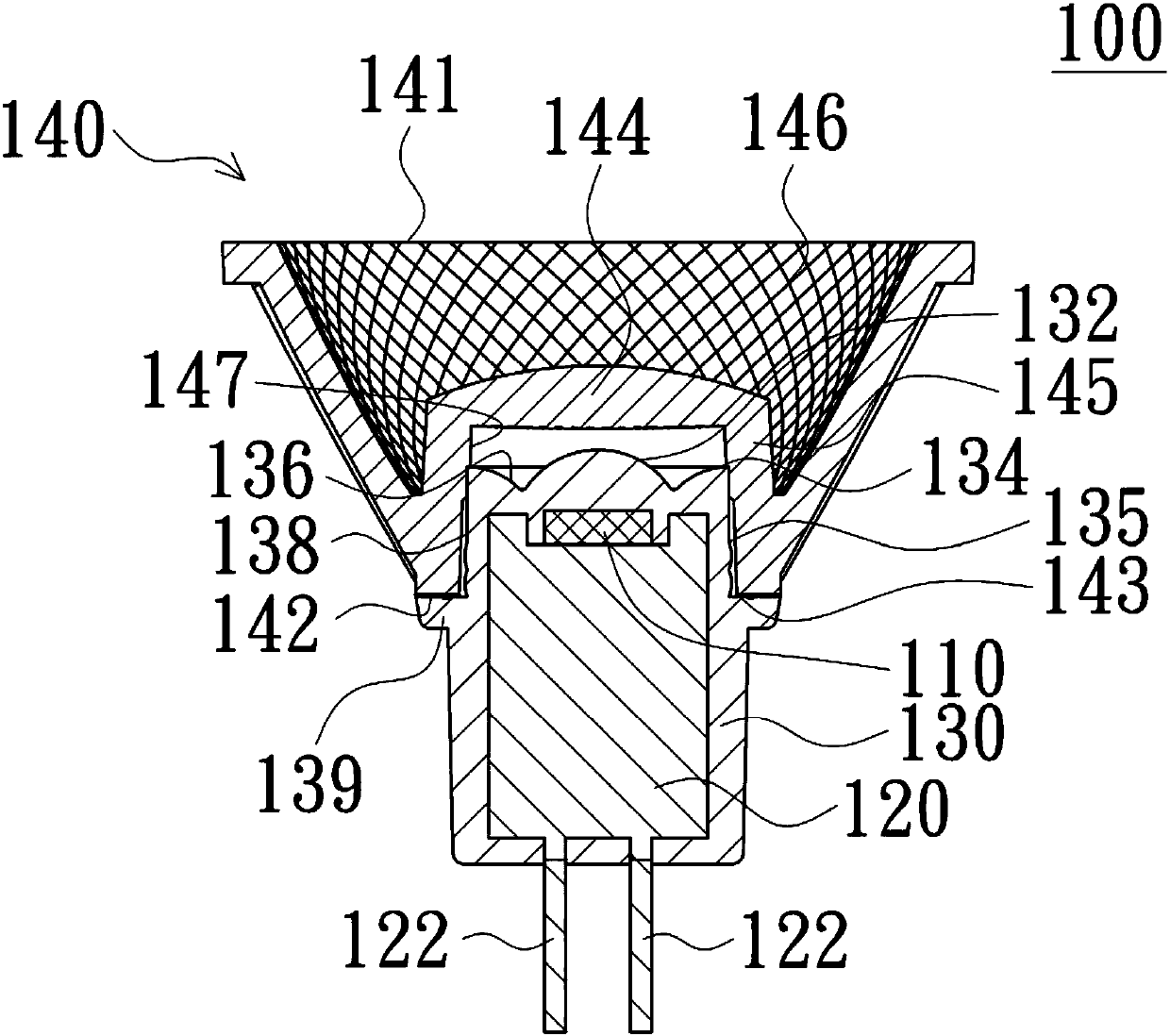

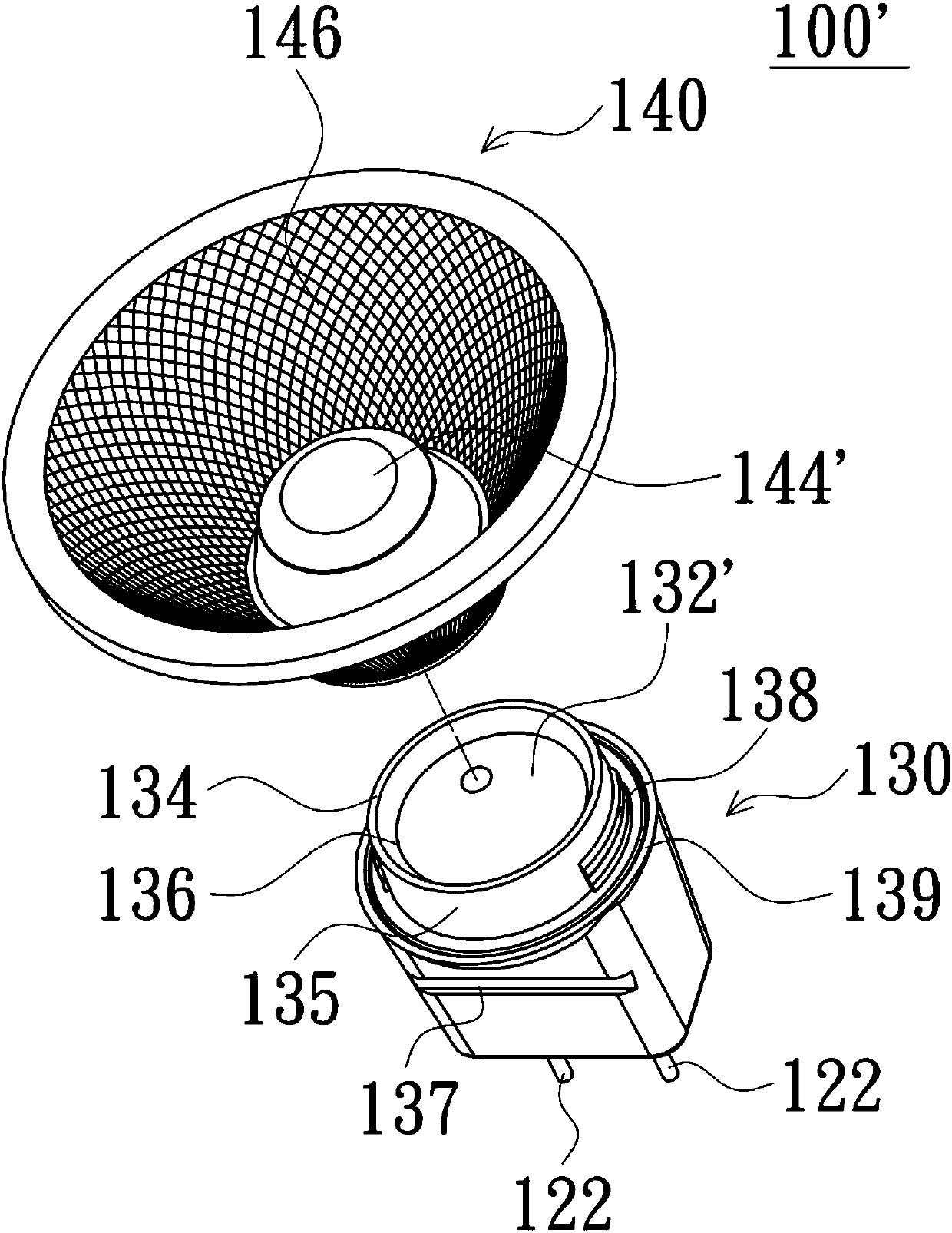

[0024] see figure 1 and figure 2 , which represents an embodiment of the lamp of the present invention. The lamp 100 of the present invention includes a semiconductor light emitting component 110 , a carrier 120 and a covering 130 . The carrier 120 carries the semiconductor light emitting component 110, the covering part 130 covers the semiconductor light emitting component 110 and the carrier 120 and has a first lens 132 covering the semiconductor light emitting component 110, wherein the covering part 130 is an integrally formed structure, and the semiconductor light emitting The light emitted by the component 110 passes through the first lens 132 . In this embodiment, the covering member 130 has a top 134 , and a recess 136 is formed on the top 134 , and the first lens 132 is disposed in the recess 136 and located above the semiconductor light emitting device 110 .

[0025] In this embodiment, the covering member 130 can integrally encapsulate the semiconductor light em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com