Tensioning chain type conveyer

A chain conveyor and tensioning technology, which is applied in the field of conveying machinery, can solve problems such as poor coordination between the conveying pipe chain and the conveying pipe, reduced service life of the pipe chain conveyor, wear and tear of the conveying pipe chain and pipe chain sprockets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

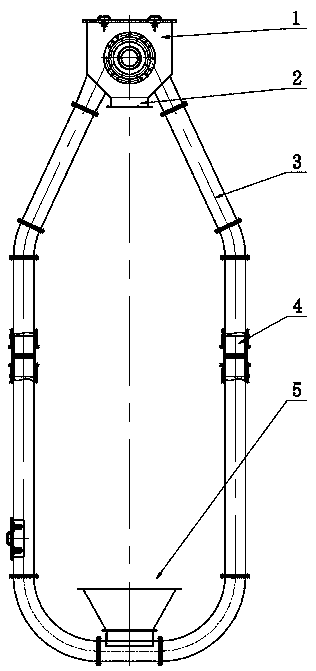

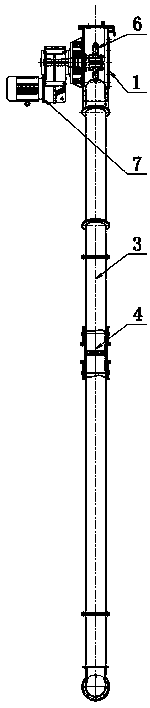

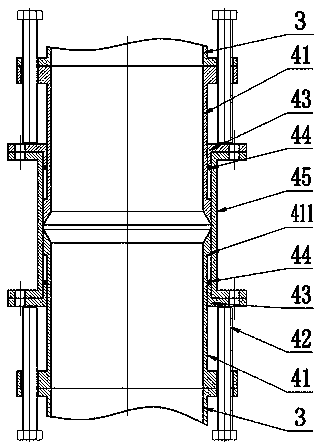

[0017] exist figure 1 and figure 2 In the shown tension chain conveyor, the conveying pipeline 3 is a channel for transporting materials with a circular cross-section, and the conveying pipeline 3 is provided with telescopic pipe joints 4, and the conveying pipe 3 provided with the telescopic pipe joints 4 is in an annular structure, A feed port 5 and a discharge port 2 are arranged on the conveying pipeline 3, and the two ends of the conveying pipeline 3 are connected through the drive box 1, and the drive box 1 is provided with a pipe chain drive sprocket 6, and the pipe chain drive sprocket 6 is connected to the drive The motor 7 is connected, and the driving motor drives the conveying pipe chain through the pipe chain drive sprocket 6 to run in the conveying pipe 3, and the conveying pipe chain will transport the material to be conveyed from the feed port 5 to the discharge port 2. The telescopic pipe joints 4 are arranged in pairs in the conveying pipeline 3, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com