A rjm integrated process water treatment equipment

A technology for treating equipment and process water, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Smooth and other problems, to achieve the effect of improved sedimentation, uniform pressure, and overcome easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

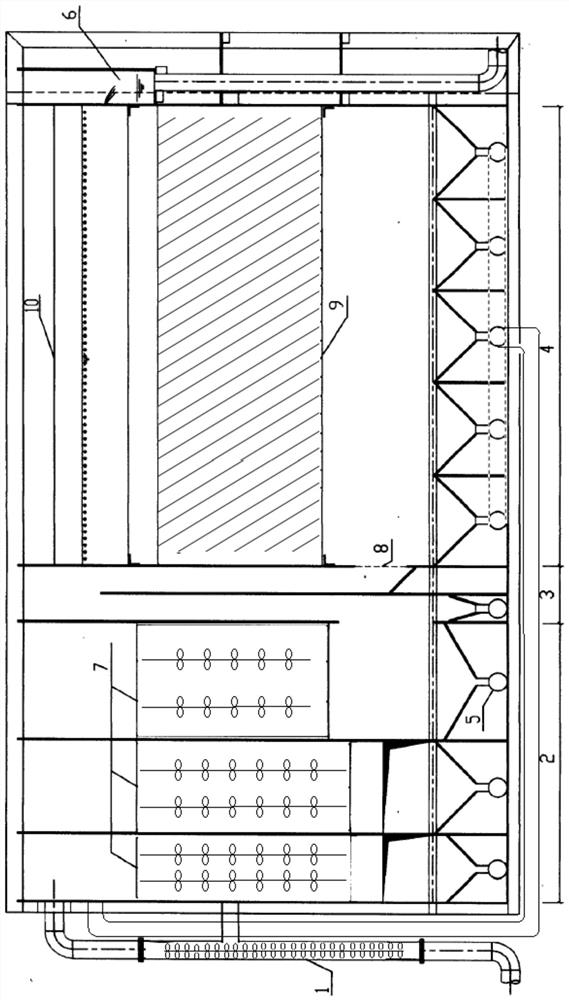

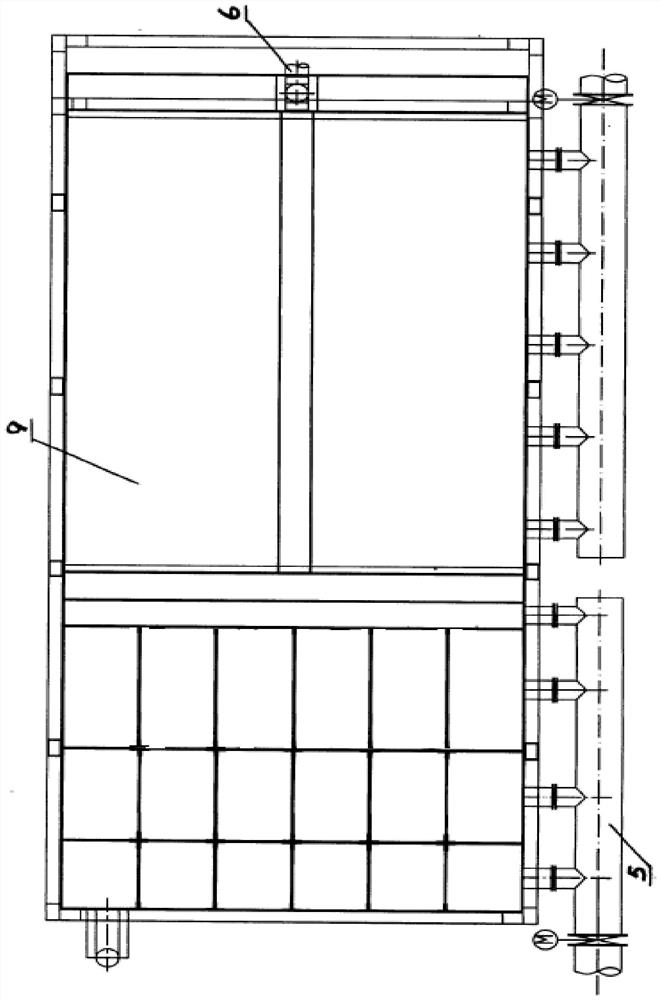

[0056] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a kind of RJM integrated process water treatment equipment of this embodiment, it includes tubular mixer 1, flocculation reaction tank 2, sedimentation tank 4, mud discharge system 5 and outlet channel 6, flocculation reaction tank 2 and sedimentation tank The lower part of the pool 4 is equipped with a mud discharge system 5, the tubular mixer 1 is connected to the upper part of the flocculation reaction tank 2, the sedimentation tank 4 is installed on one side of the flocculation reaction tank 2, and the outlet channel 6 is connected to the upper part of the sedimentation tank 4. It also includes a transition pipe section 3, water distribution equipment 8 and sludge water return pipe 17. The pipe mixer 1 is a strong turbulent flow mixer. The pipe mixer 1 and the flocculation reaction tank 2 are connected through the transition pipe section 3. Installed in the transition pipe sect...

specific Embodiment approach 2

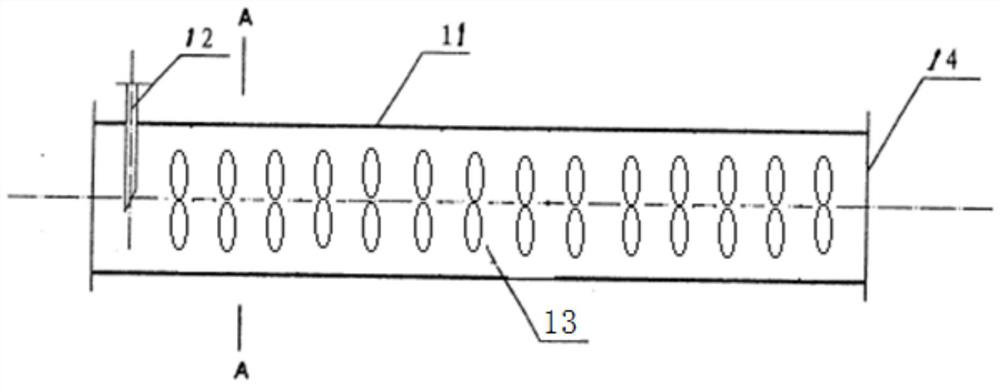

[0059] Specific implementation mode two: combination image 3 , Figure 4 , Figure 7 to Figure 18 Describe this embodiment, the tubular mixer 1 of this embodiment comprises mixer tube wall 11, dosing tube 12, flange plate 14 and strong turbulence member 13, and flange plate 14 is installed on one end of mixer tube wall 11 And connected with the tube mixer 1, the dosing tube 12 is installed on the mixer tube wall 11 and communicates with the inside of the mixer tube wall 11, and the strong turbulence member 13 is installed on the tube mixer along the length direction of the tube mixer 11. in mixer 11. So set, the mixing time is shortened. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0060] Specific implementation mode three: combination image 3 , Figure 4 , Figure 7 to Figure 18 Describe this embodiment, the strong turbulence member 13 of this embodiment includes a paddle shaft 13-1 and a plurality of paddles 13-2, the paddle shaft 13-1 is installed in the mixer pipe wall 11 along the length direction, and the multiple paddles 13-2 rotation is sleeved on the paddle shaft 13-1. So set, the mixing time is shortened. Other compositions and connections are the same as those in the second embodiment.

[0061] The strong turbulence member 13 of this embodiment also includes a plurality of support frames and a plurality of sealed bearings, and the plurality of support frames are sleeved on the paddle shaft 13-1, and support the mixer tube wall 11 and the paddle shaft 13-1. The support frame is a "ten"-shaped support frame with a shaft hole in the middle, and a plurality of blades 13-2 are rotatably fitted on the paddle shaft 13-1 through a plurality of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com