Surface quality detection device and method for ellipsoidal glass shell

A technology of surface quality and detection device, which can be used in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

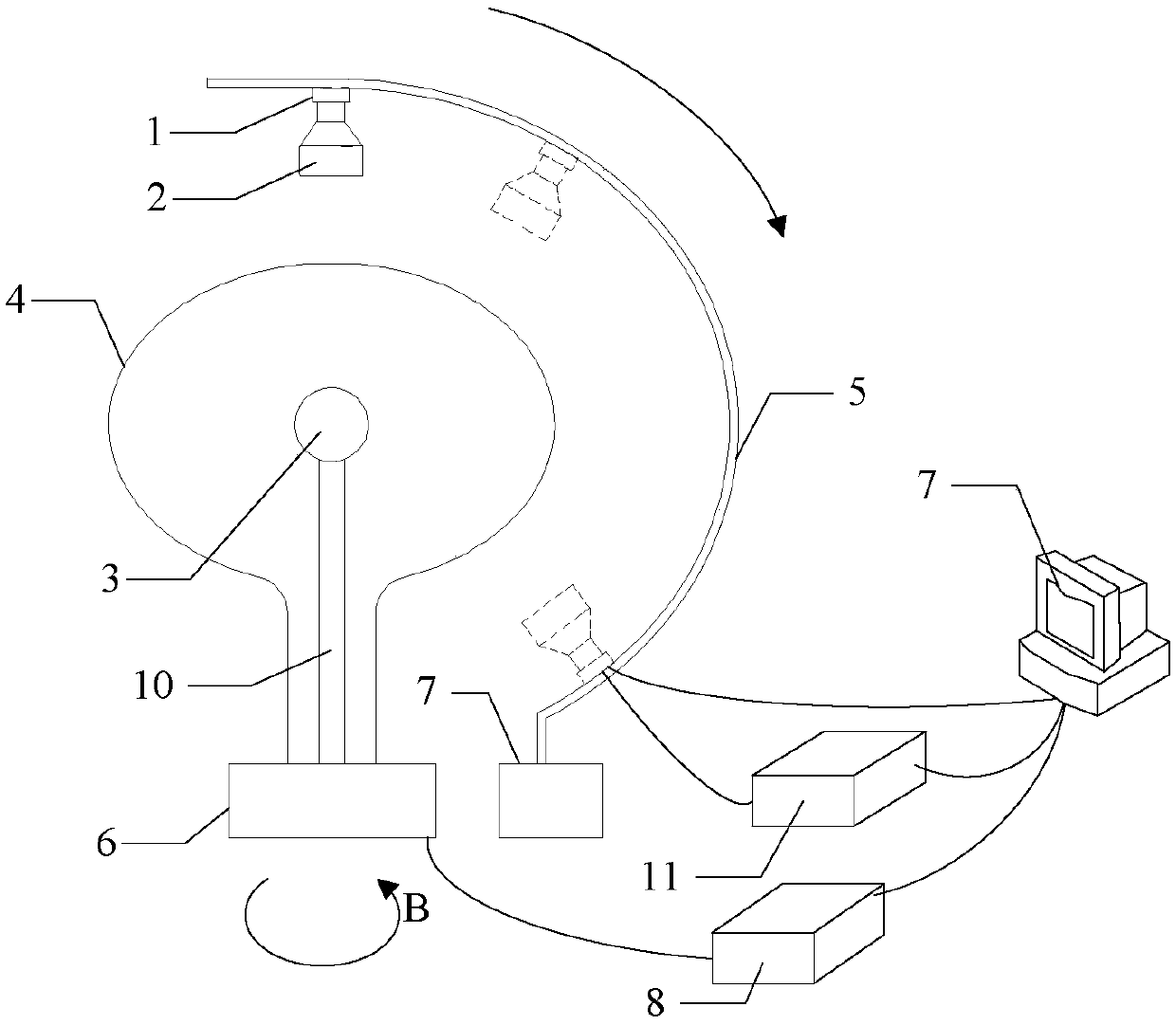

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, an ellipsoidal glass bulb surface quality detection device described in this embodiment, including an industrial camera 1, a telecentric lens 2, a light source 3, a support frame 10, a guide rail 5, a turntable 6, and a stepping motor No. 1 Controller 8 and No. 2 stepper motor controller 11;

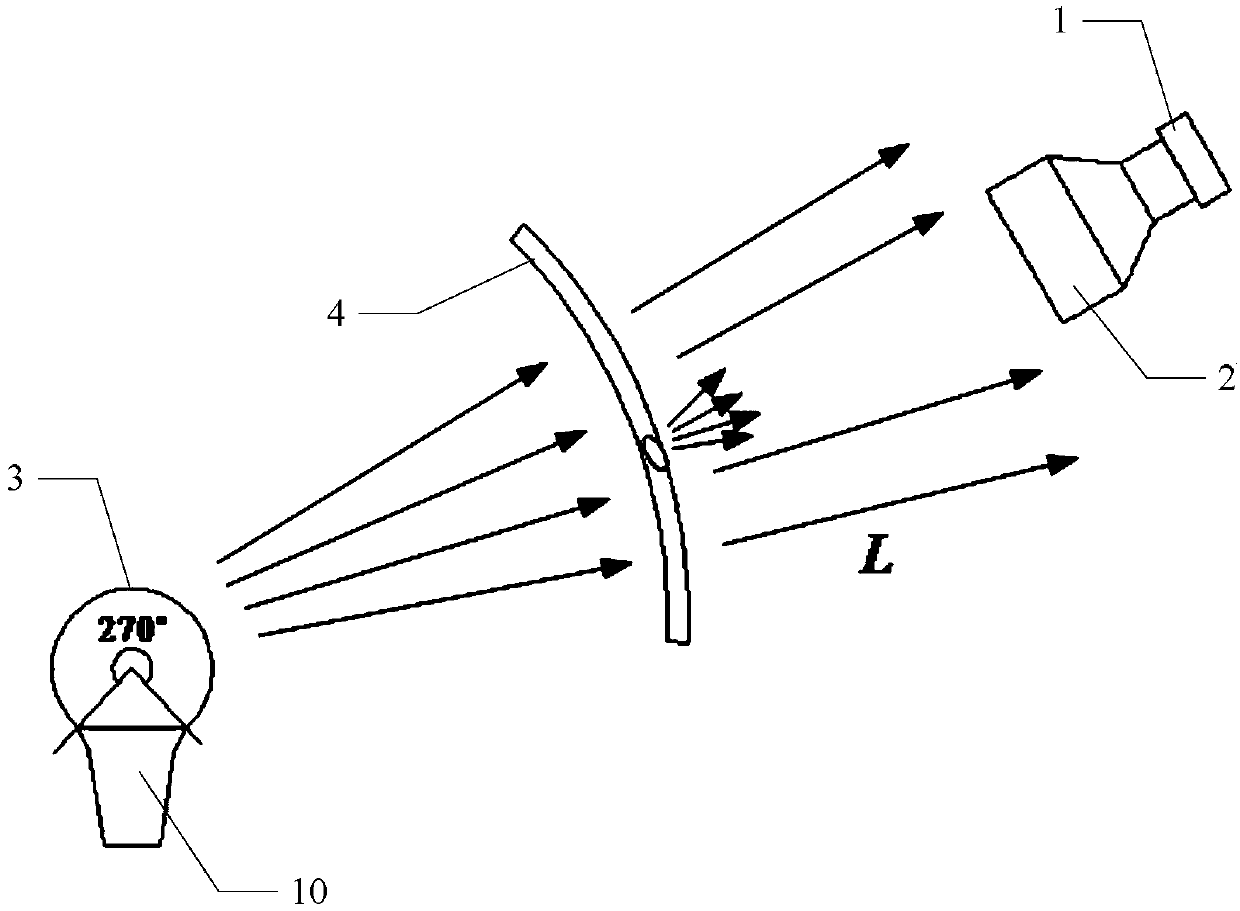

[0029] The lower end of the support frame 10 is fixed at the center of rotation of the turntable 6, the light source 3 is fixed on the top of the support frame 10, the measured ellipsoidal glass bulb 4 is fastened on the turntable 6, and the light source 3 is positioned on the measured ellipsoidal glass bulb 4 The height of the support frame 10 is adjustable so as to ensure that the light source 3 is located at the center of the measured ellipsoidal glass bulb 4; at the same time, the size of the turntable 6 ensures that the measured ellipsoidal glass bulb 4 can be placed stably and coaxially rotated;

...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment further limits the surface quality detection device of an ellipsoidal glass bulb described in Embodiment 1. In this embodiment, the light source 3 is a white light source that emits uniform light.

[0039] In this embodiment, the white light source with uniform light emission can make the brightness of the image taken by the industrial camera 1 consistent, and it is more convenient and accurate when splicing images, and avoids errors caused by the uneven light emission of the light source 3 .

specific Embodiment approach 3

[0040] Specific embodiment three: this embodiment is to further limit the surface quality detection device of a kind of ellipsoidal glass bulb described in specific embodiment one, in this embodiment, the length of the major axis of the ellipse where the guide rail 5 is located is the length of the measured ellipse The length of the semimajor axis of the spherical glass bulb 4 plus the working distance of the industrial camera 1 and the length of the industrial camera 1, the length of the semiminor axis of the ellipse where the guide rail 5 is located is the length of the semiminor axis of the measured ellipsoidal glass bulb 4 plus the length of the industrial camera 1. The working distance of the camera 1 and the length of the industrial camera 1.

[0041]In this embodiment, the detection result is more accurate by ensuring the working distance of the industrial camera 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com