Composite material damage detection method based on wavelet analysis

A composite material and wavelet analysis technology, which is applied in the analysis of materials, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves. To achieve the effect of reducing the number of acquired and processed damage signals, reducing the number of polling, and improving the efficiency of damage monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

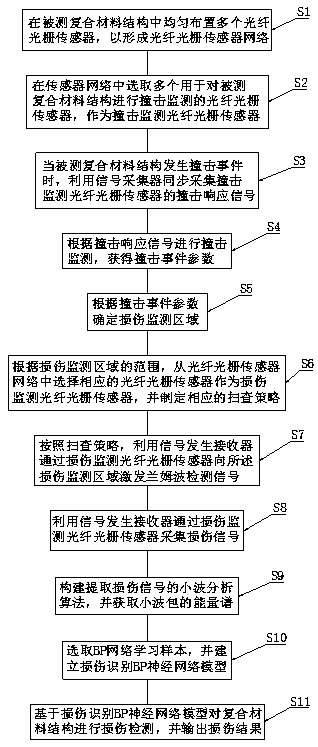

[0033] see figure 1 , a composite damage detection method based on wavelet analysis, comprising the following steps:

[0034] Step S1: uniformly arrange a plurality of FBG sensors in the composite material structure to be tested to form a FBG sensor network.

[0035] The number and arrangement of fiber grating sensors that make up the fiber grating sensor network are determined according to actual needs. In the process of arranging fiber grating sensors, it is necessary to ensure that the arrangement is as uniform as possible;

[0036] Step S2: selecting a plurality of FBG sensors for impact monitoring of the composite material structure under test in the sensor network as the impact monitoring FBG sensors.

[0037] In this step, the entire FBG sensor network arranged in the composite material structure under test is used for subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com