Improved electricity utilization plugging component

An improved, component technology, applied in the direction of electrical components, circuits, contact parts, etc., can solve the problems of death, potential safety hazards, separation of plug connectors and socket sockets, etc., to achieve convenient use, reduce electric shock accidents, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

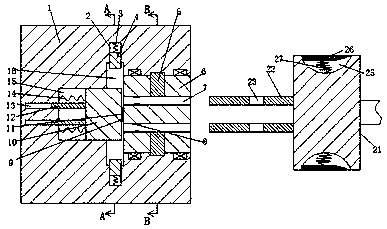

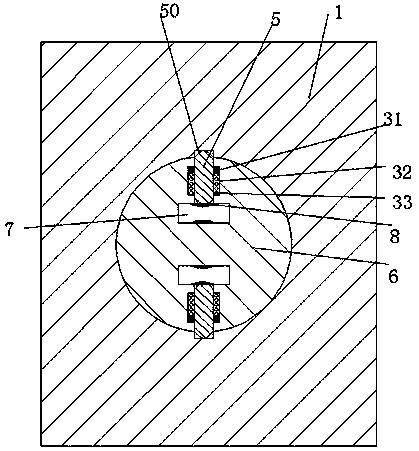

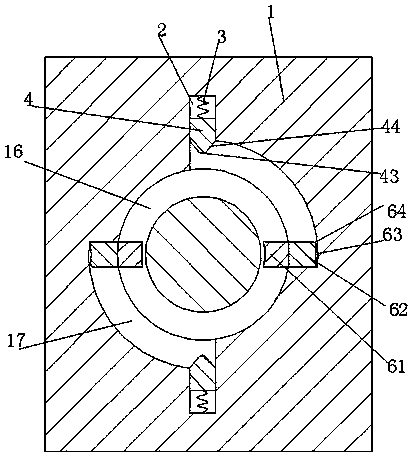

[0027] Combine below Figure 1-7 The present invention will be described in detail.

[0028] refer to Figure 1-7 , an improved electrical plug-in assembly according to an embodiment of the present invention, including a socket socket fixedly installed in the wall and a plug connector 21 connected to an electrical device, the socket socket 1 is provided with an opening facing In the right rotation hole, a rotating member 6 is rotatably installed in the rotating hole. In the rotating member 6, there are symmetrically arranged up and down connecting grooves 7 connecting left and right, and elastic conductive sheets are fixedly installed in the connecting groove 7. 8. A rubber sheet 11 is fixedly installed at the center of the left end surface of the rotating member 6, and the left end surface of the rubber sheet 11 is provided with a concave hole, and the socket 1 is provided with a circular groove 16 at the left end of the rotating hole. The center of the left end of the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com