Patents

Literature

53results about How to "Allow rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

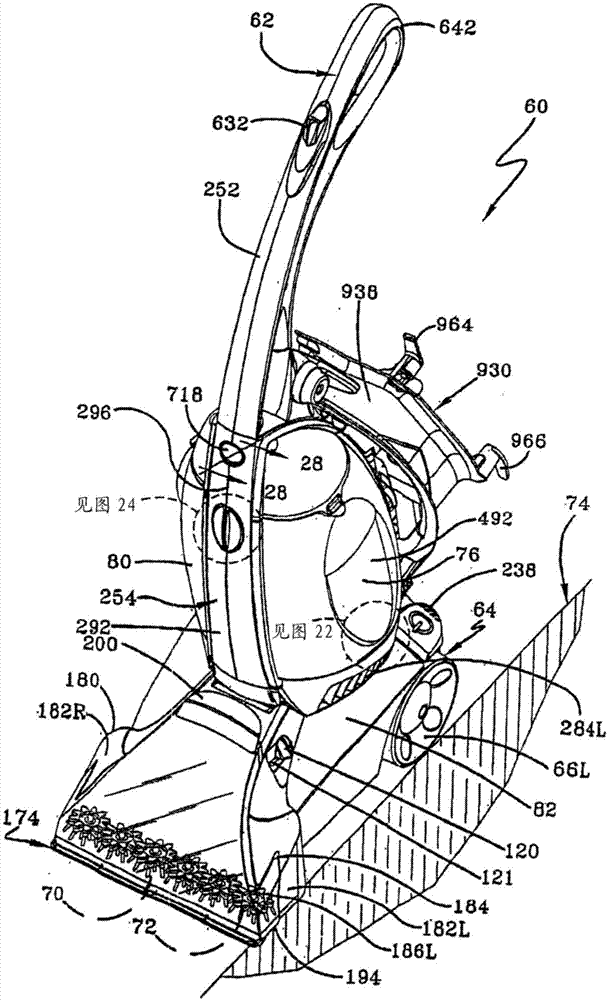

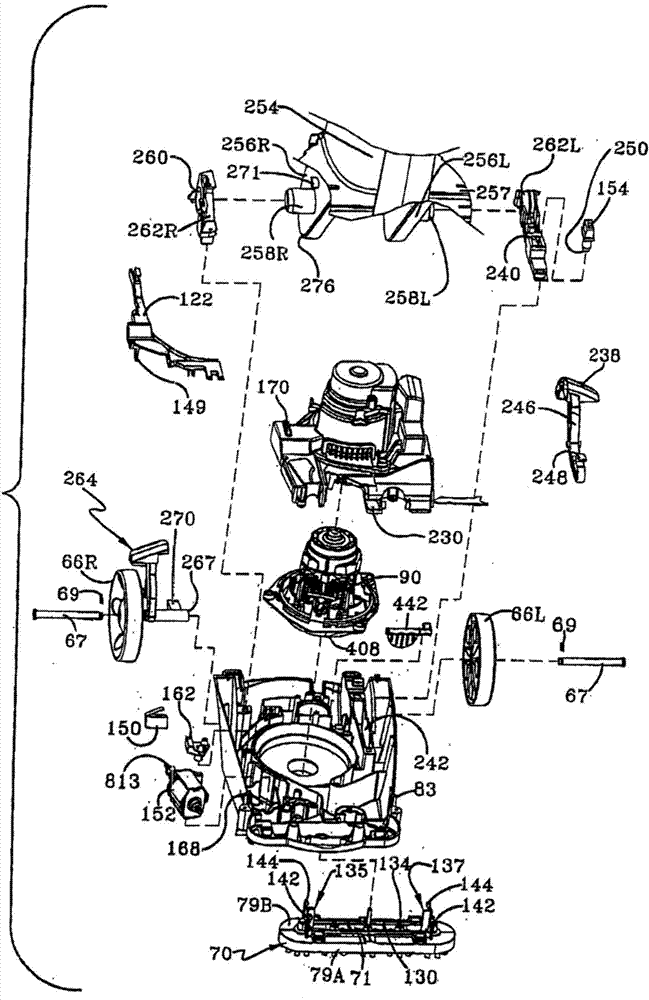

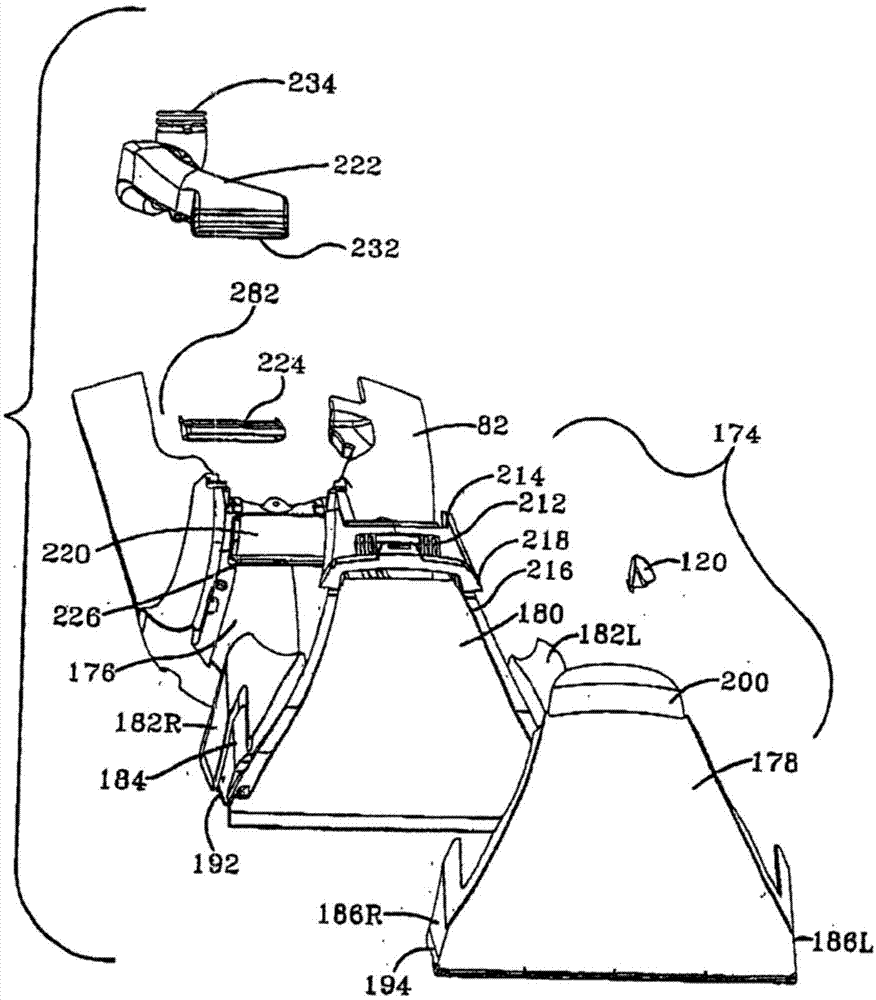

Cleaning apparatus

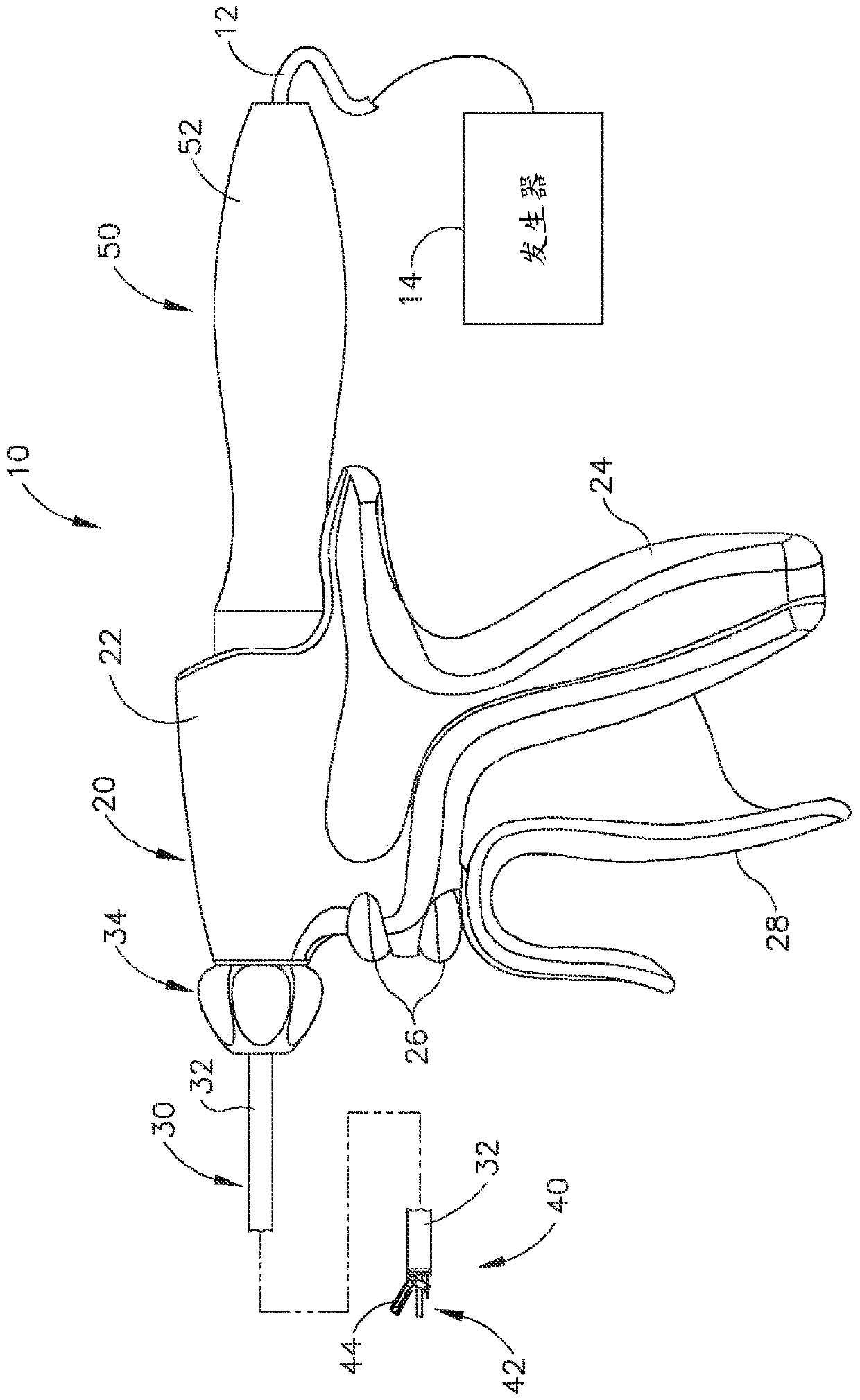

A cleaning apparatus for cleaning a surface in which cleaning solution is dispensed to the surface and substantially simultaneously extracted along with the dirt on the surface in a continuous operation is provided. The cleaning apparatus includes a housing, a solution tank for supplying a flow of cleaning solution to the surface, the solution tank being removably mounted to said housing, a recovery tank removably mounted to the housing, a suction nozzle secured to the housing and in fluid communication with the recovery tank and a suction source in fluid communication with the suction nozzle for generating suction to draw dirt and liquid through the suction nozzle and into the recovery tank. A latching assembly is operatively connected to said solution tank and recovery tanks to releasably latch the tanks to the housing. An actuator is provided for engagement by a user to selectively simultaneously unlatch both the recovery tank and the solution tank.

Owner:TECHTRONIC FLOOR CARE TECH LTD

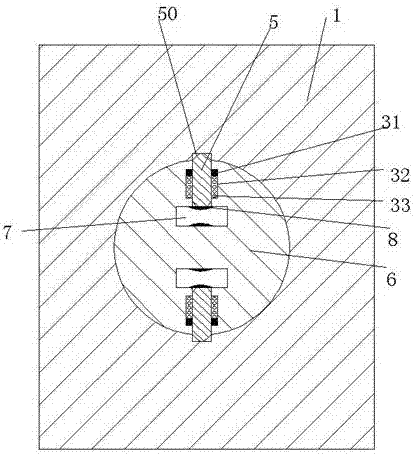

Novel dust remover device

InactiveCN107115066APrevent rotationSimple structureElectric equipment installationElectricityEngineering

A new type of dust collector device, including a socket and a plug connected to the dust collector, the socket is provided with a screw hole with the opening facing right, and a screw is rotatably installed in the screw hole. The left and right connecting slots are provided in the screwing part, and the inserting slot is fixedly installed with the bullet clip. The washer is fixedly installed at the middle end of the left end face of the screwing part, and the left end face of the washer is provided with a hole slot. The seat is provided with an annular groove at the left end of the screwing hole, and a middle end groove is arranged at the middle end of the left end of the annular groove, and a sliding part is installed in the middle end groove so as to slide left and right, and the middle end of the right end surface of the sliding part is fixedly installed. There are nails, and the end wall of the annular groove is provided with an arc-shaped groove located at the rear upper part of the sliding part and at the front lower part of the sliding part. The upper and lower indentation grooves extending up and down are arranged in the end wall of the annular groove commensurate with each other. The arc-shaped grooves are connected, and the power supply block is slidably installed in the indented grooves.

Owner:张鑫祥

Novel water cup device

InactiveCN107307704APrevent rotationSimple structureCoupling device detailsWater-boiling vesselsMating connectionEngineering

The invention provides a novel water cup device. The device includes a water cup, a plug and a socket, wherein the plug is electrically connected with the water cup through a power line, and the socket is connected with the plug in a cooperation mode; the end face of the right side of the water cup is provided with a handle, the socket is internally provided with a rotating hole with a port facing to the right, a rotating component is rotatably installed in the rotating hole, inserted grooves symmetrical up and down are arranged in the rotating component and communicated left and right, conductive sheets are fixedly installed in the inserted grooves, the middle of the left end face of the rotating component is fixedly provided with a gasket, the left end face of the gasket is provided with a groove hole, the socket is located at the left end of the rotating hole and is provided with a ring groove, the middle of the left end of the ring groove is provided with a middle groove, a sliding part which can slide left and right is installed in the middle groove, the middle of the right end face of the sliding part is fixedly provided with a pin rod, the end wall of the ring groove is internally provided with half-ring grooves located on the back upper portion of the sliding part and the front lower portion of the sliding part respectively, the end wall of the ring groove is internally provided with contraction grooves which are symmetrical up and down and can extend up and down, the contraction grooves are communicated with the half-ring grooves, and electricity transmission blocks are installed in the contraction grooves in a sliding mode.

Owner:何杨波

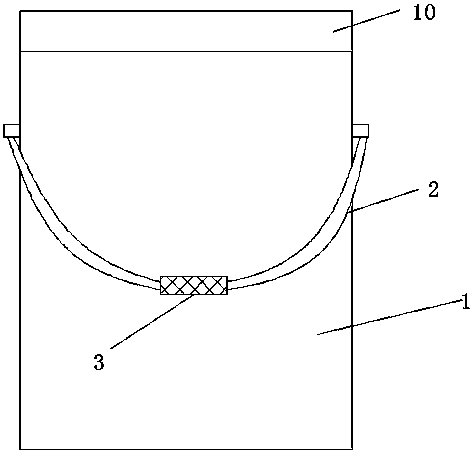

Mailbox device

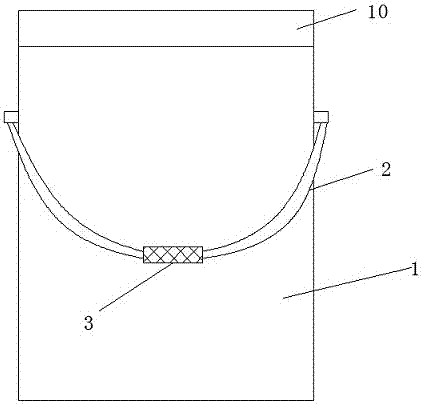

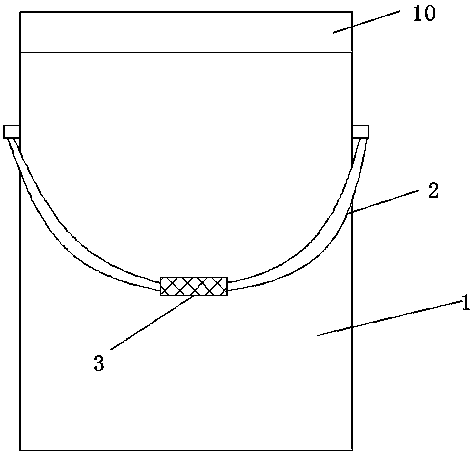

ActiveCN107348811ASimple structureEasy to assemble and disassembleKitchen equipmentDomestic articlesAgricultural engineering

Disclosed is a mailbox device. The mailbox device comprises a mailbox, a sleeve shell and a box cover, wherein the sleeve shell is fixedly arranged at the top of the mailbox, and the box cover is matched with the sleeve shell; the front end surface of the mailbox is provided with a delivery port for putting letters, and a convex eaves plate is fixedly arranged at the front end surface, above the delivery port, of the mailbox; the sleeve shell is internally provided with a convex block, and the convex block is provided with a first bevel surface; the lower end of the box cover is provided with a second bevel surface matched with the first bevel surface; lock grooves are formed in the inner wall of the sleeve shell in a left-right symmetrical mode; the middle of the upper end surface of the box cover is provided with a first transfer groove with an opening facing upwards, the lower end of the first transfer groove is provided with a second transfer groove, the lower end of the second transfer groove is provided with a third transfer groove, retraction grooves communicated with the exterior are symmetrically formed in the left and right sides of the third transfer groove, and a transfer plate is rotatably installed in the third transfer groove.

Owner:山东可可西里科技有限公司

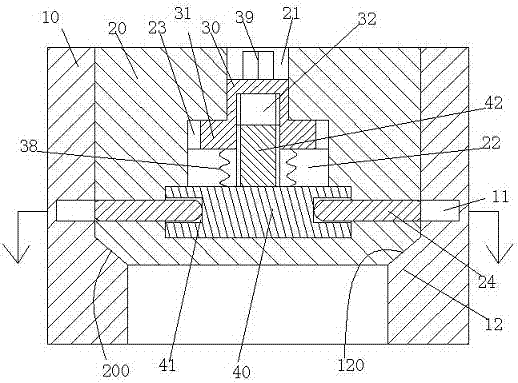

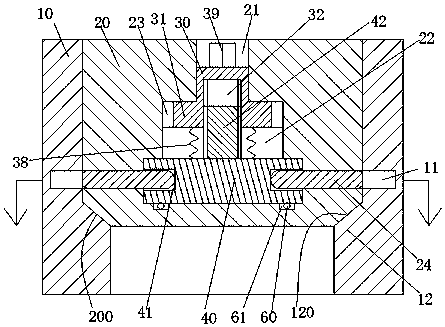

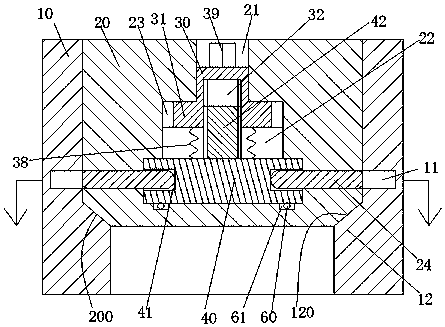

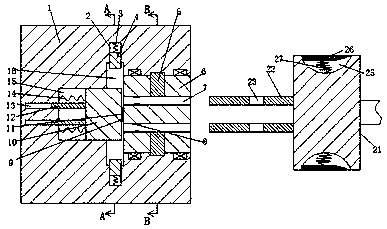

Electrical plugging assembly

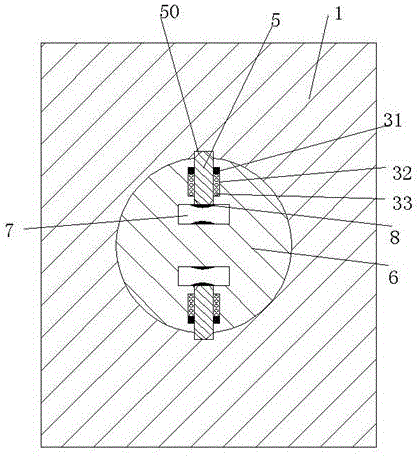

ActiveCN107257065APrevent rotationSimple structureCoupling device detailsEngineeringMechanical engineering

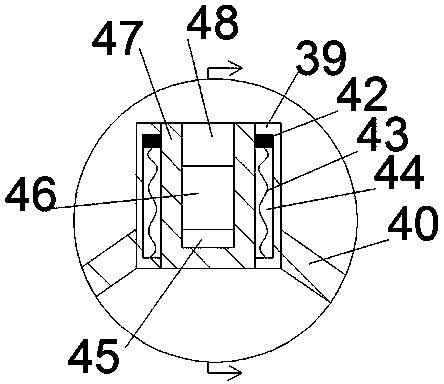

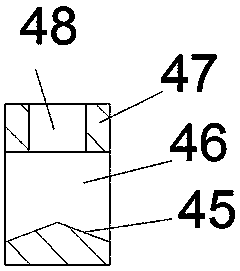

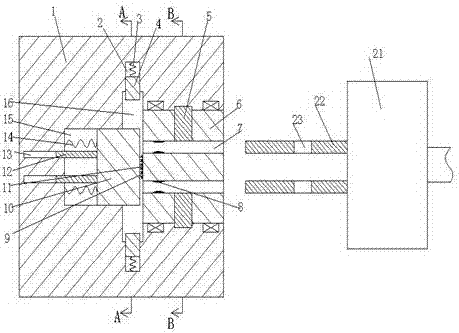

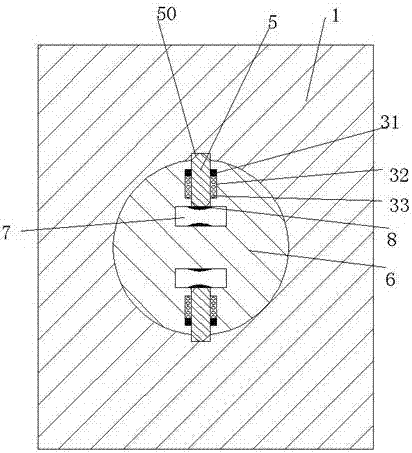

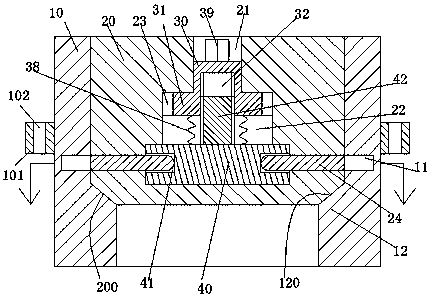

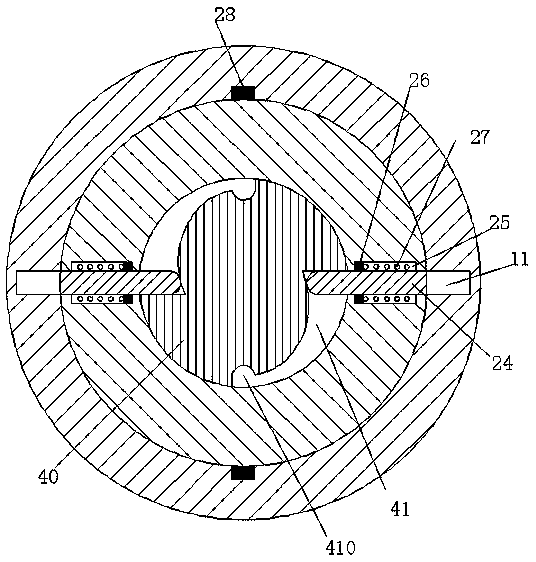

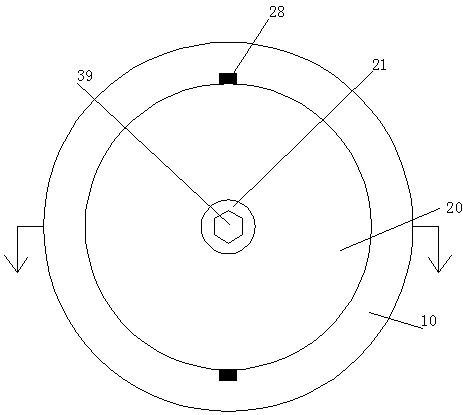

The invention relates to an electrical plugging assembly comprising a plugging base fixedly installed in a wall and a plugging head connected with an electrical device. A rotating hole with an opening to the right is formed in the plugging base; a rotating element is installed in the rotating hole is a rotatable manner; plugging slots that are arranged in a up-down symmetric manner and are communicated in a left-right manner are formed in the rotating element; and elastic conductive pieces are fixedly installed in the plugging slots. A rubber sheet is fixedly installed in the center of the left end surface of the rotating element; and a recession hole is formed in the left end surface of the rubber sheet. A circular groove is formed in the plugging base at the left end of the rotating hole; a central groove is formed in the center of the left end of the circular groove; a sliding element is installed in the central groove in a left-right sliding manner; and a pin is fixedly installed in the center of the right end surface of the sliding element. Arc rotating slots are formed above the rear of the sliding element and below the front of the sliding element in the end wall of the circular groove; extension slots extending up and down are formed in the end wall of the circular groove in an up-down symmetric manner; the extension slots and the arc rotating slots are communicated; and power supply blocks are installed in the extension slots in a sliding manner.

Owner:JIASHAN HUIJIALE DECORATION MATERIALS CO LTD

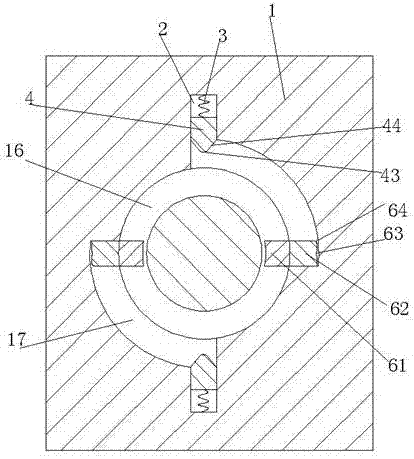

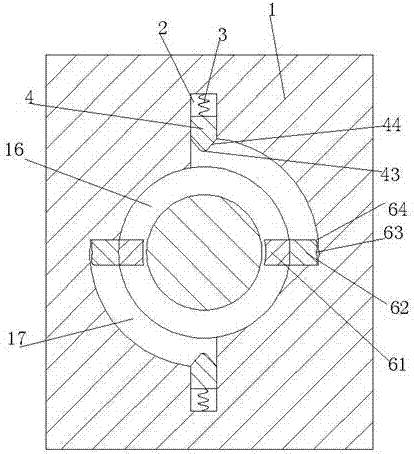

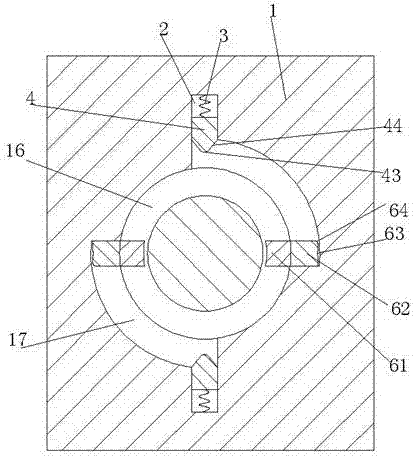

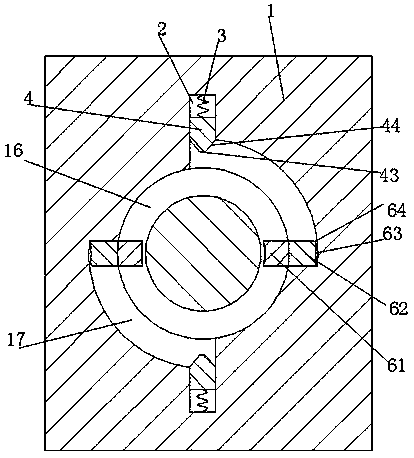

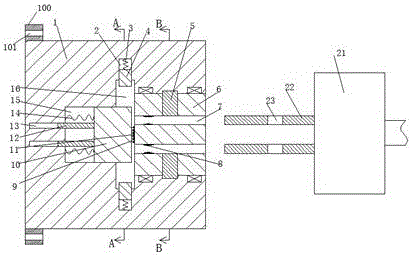

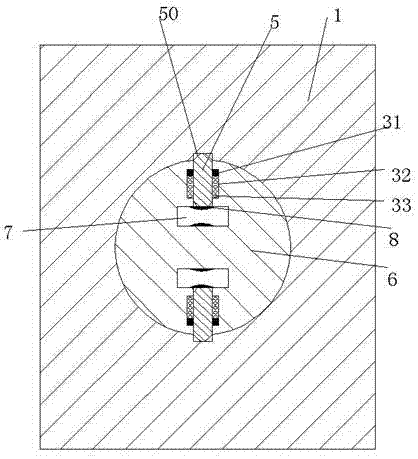

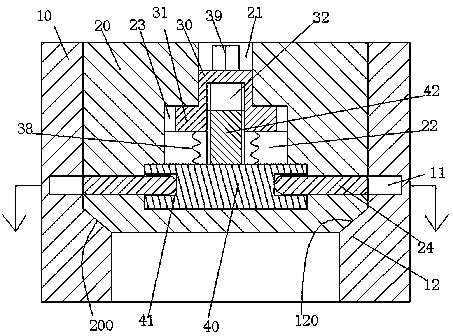

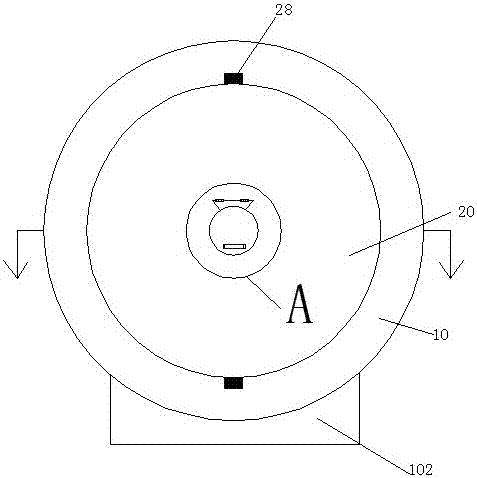

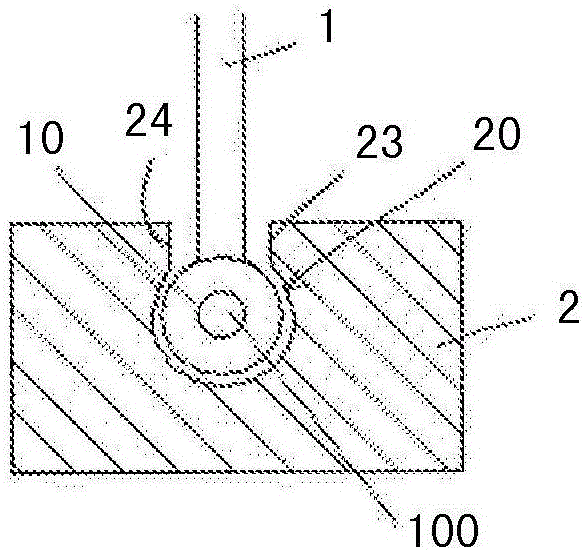

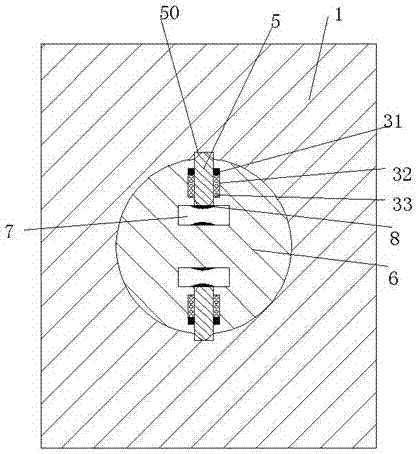

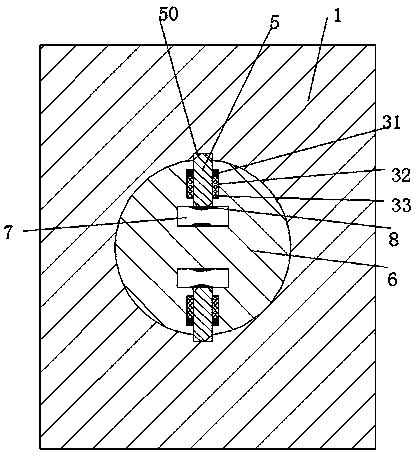

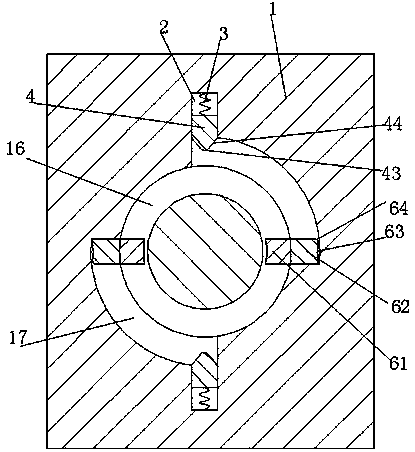

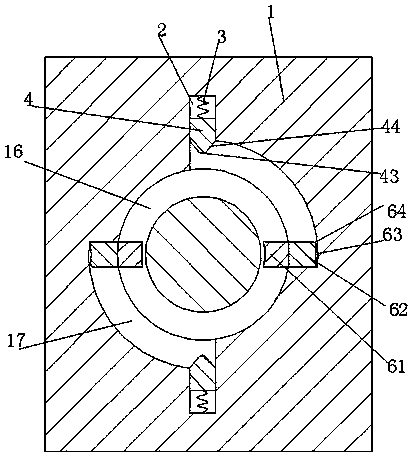

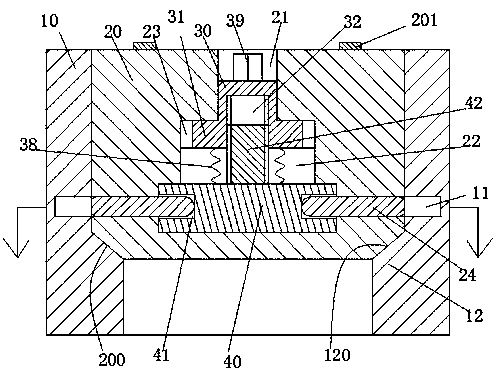

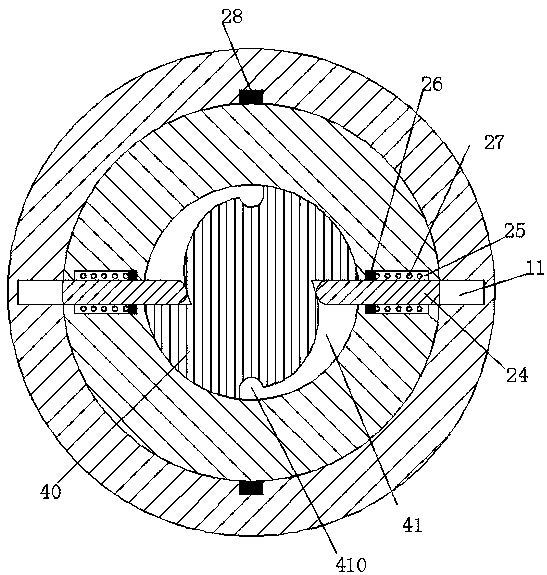

Coronary-heart-disease-resistant drug device

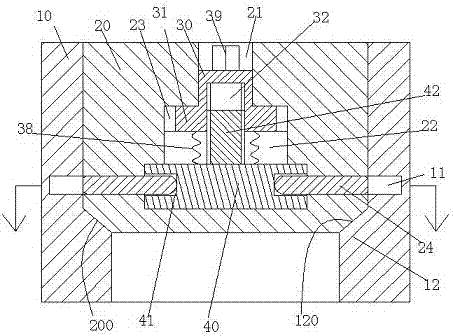

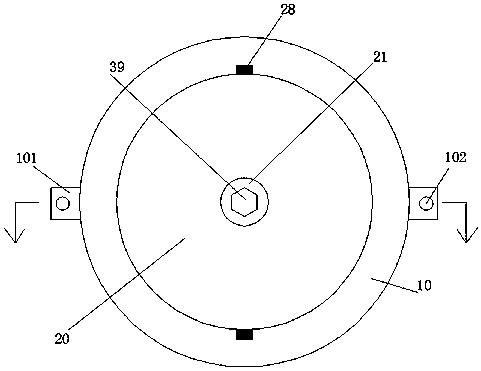

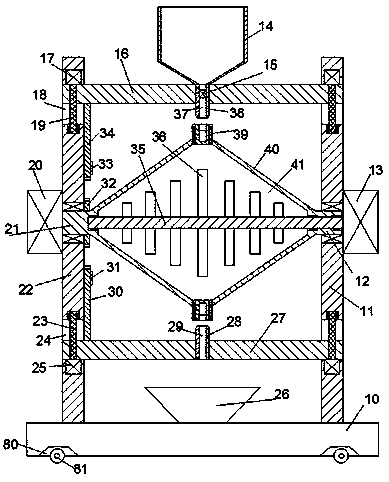

InactiveCN108404766AAllow rotationAvoid accidental rotationRotating receptacle mixersTransportation and packagingMedicinePharmaceutical drug

The invention discloses a coronary-heart-disease-resistant drug device which comprises a base, a left support and a right support, wherein the left support and the right support are fixedly mounted onthe base. A mixing cylinder is arranged between the left support and the right support, a mixing cavity is formed in the mixing cylinder, a left rotating shaft and a right rotating shaft are arrangedat the outer left end and the right outer end of the mixing cylinder, the left rotating shaft and the right rotating shaft are rotatably mounted in the left support and the right support, the left rotating shaft is in power connection with a first motor fixedly mounted on the left end surface of the left support, a horizontal extending stirring shaft is arranged in the mixing cavity, the left endof the stirring shaft is rotatably mounted in the rotating shaft, the right end is rotatably mounted in the right rotating shaft and in power connection with a second motor fixedly mounted on the right end surface of the right support, stirring blades are arranged on the stirring shaft, vertically symmetrical outward extending guide pipes are arranged in the mixing cylinder, first through cavities comminuted with the mixing cavity and the outside are formed in the guide pipes, and extending blocks can vertically slide and are mounted in the first through cavities.

Owner:林桂花

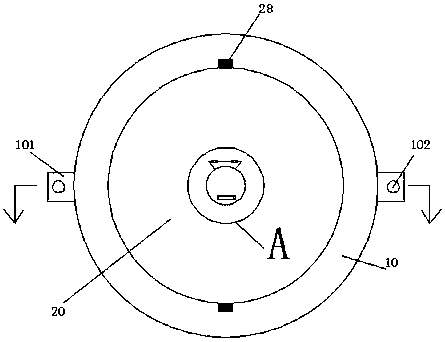

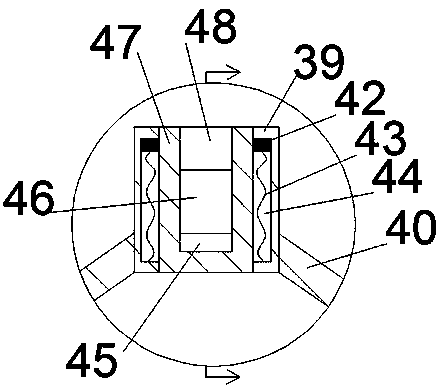

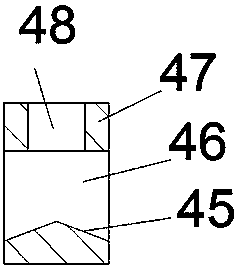

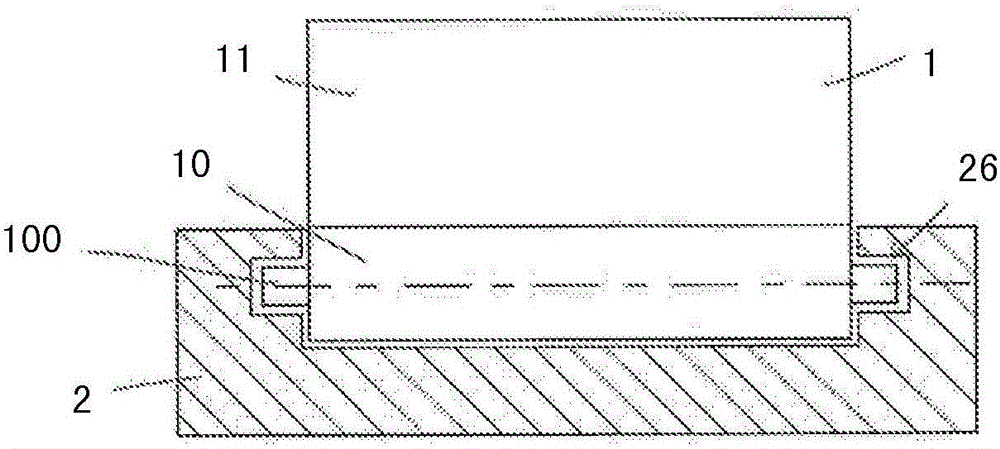

Water cup device

InactiveCN107332049APrevent rotationSimple structureCoupling device engaging/disengagingCoupling device detailsCross-linkMating connection

A water cup device, a water cup, a plug electrically connected to the water cup through a power cord, and a socket cooperating with the plug, a handle is provided on the right side of the water cup, and a rotating hole with the port facing the right is provided in the socket, and the rotating hole is rotatably installed There is a rotating part, and the upper and lower parts of the rotating part are arranged with the left and right connecting slots, the conductive sheet is fixedly installed in the slot, the gasket is fixedly installed in the middle of the left end surface of the rotating part, and the left end surface of the gasket is provided with a slot hole, the socket A ring groove is arranged at the left end of the rotation hole, and a middle groove is arranged in the middle of the left end of the ring groove. A sliding piece is installed in the middle groove to slide left and right. A pin rod is fixedly installed in the middle of the right end surface of the sliding piece. The semi-circular groove located at the upper rear of the slider and the lower front of the slider. The upper and lower sides of the annular groove are symmetrically arranged with indentation grooves extending up and down. piece.

Owner:何杨波

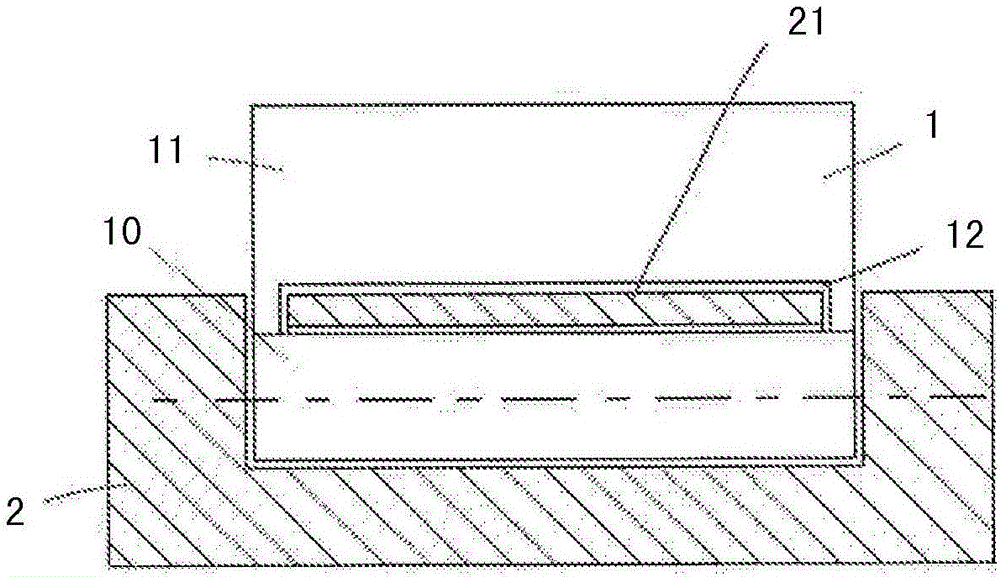

Improved water cup device

InactiveCN108242657ASimple structureEasy to useLive contact access preventionPower transmissionMechanical engineering

The invention proposes an improved water cup device, which includes a water cup, a plug electrically connected with the water cup through a power cord and a socket connected cooperatively with the plug. A handle is arranged on the end face at a right side of the water cup. A rotation hole with a port facing rightward is arranged in the socket. A rotating member is mounted rotatably in the rotationhole. Laterally communicating slots are arranged symmetrically at the top and bottom in the rotating member. Conductive pieces are fixedly mounted in the slots. A gasket is fixedly mounted in the middle of the left end face of the rotating member, and a slotted hole is disposed in the left end face of the gasket. An annular groove is arranged in the socket and located at the left end of the rotation hole. An intermediate groove is disposed in the middle of the left end of the annular groove. A gliding member is mounted slidably on the right and left in the intermediate groove. A pin rod is fixedly arranged in the middle of the right end face of the gliding member. Semi-ring grooves which are located above the rear of the gliding member and below the front of the gliding member are disposed in the end wall of the annular groove. Retractable grooves extending up and down are disposed symmetrically at the top and bottom in the end wall of the annular groove. The retractable grooves communicate with the semi-ring grooves. Power transmission blocks are mounted slidably in the retractable grooves.

Owner:贾军霞

Novel electricity utilization plugging component

InactiveCN107871992APrevent rotationSimple structureLive contact access preventionElectricityRubber sheet

A novel electricity utilization plugging component comprises a bayonet socket fixedly arranged in a wall and a connecting plug connected to electric equipment. The bayonet socket is provided with a rotation hole whose opening faces towards the right. The rotation hole is rotatably provided with a rotation component. The rotation component is vertically and symmetrically provided with plug groovesconnected to left and right portions. Elastic conducting strips are fixedly installed in the plug grooves. A center of a left end surface of the rotation component is fixedly provided with a rubber sheet. A left end surface of the rubber sheet is provided with a concave hole. A left end of the bayonet socket, which is located at the rotation hole, is provided with a circular groove. A center of aleft end of the circular groove is provided with a center groove. A slide component which can slide horizontally is installed in the center groove. A center of a right end surface of the slide component is fixedly provided with a pin. An end wall of the circular groove is provided with arc rotation grooves which are located in an upper portion behind the slide component and in a lower portion in front of the slide component. The end wall of the circular groove is vertically and symmetrically provided with telescopic grooves which are extended vertically. The telescopic grooves are connected tothe arc rotation grooves. Power supply blocks are slidingly arranged in the telescopic grooves.

Owner:徐学铖

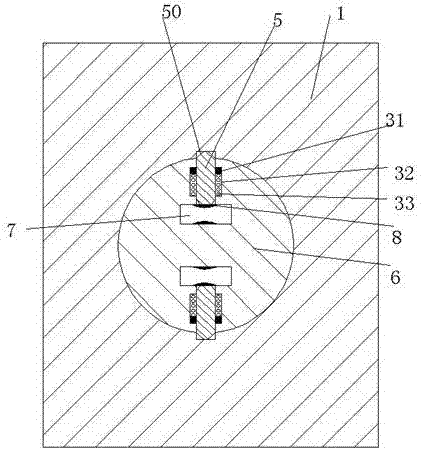

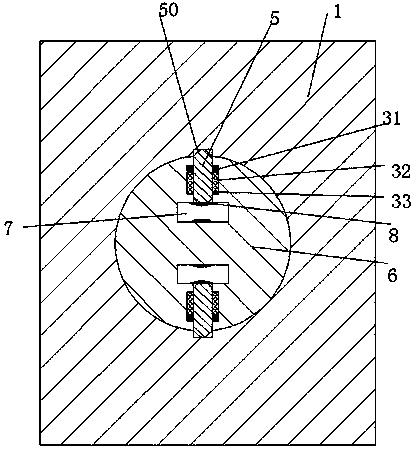

Dust collector device

InactiveCN107181110APrevent rotationSimple structureCoupling device detailsEngineeringDust collector

A dust remover device, including a socket and a plug connected to the dust remover, the socket is provided with a screw hole with the opening facing to the right, a screw is rotatably installed in the screw hole, and the screw There are left and right insertion slots that are connected up and down in the parts, and the clips are fixedly installed in the insertion slots. A washer is fixedly installed at the middle end of the left end face of the screwing part, and the left end face of the washer is provided with a hole slot. An annular groove is arranged at the left end of the screwing hole, a middle end groove is arranged at the middle end of the left end of the annular groove, a sliding piece is installed in the middle end groove so as to slide left and right, and a For inserting nails, the end wall of the annular groove is provided with an arc-shaped groove located at the rear upper part of the sliding part and at the front lower part of the sliding part. The upper and lower indentation grooves extending up and down are arranged in the end wall of the annular groove commensurate with each other. The indentation groove and the arc-shaped The slots are connected, and the power supply block is slidingly installed in the indentation slot.

Owner:张鑫祥

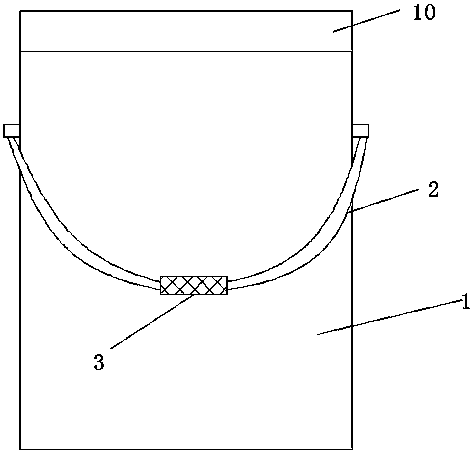

Novel environment-friendly paint barrel device

ActiveCN107487533ASimple structureEasy to assemble and disassembleRemovable lids/coversLidsEngineeringSlide plate

The invention discloses a novel environment-friendly paint barrel device. The novel environment-friendly paint barrel device comprises a barrel sleeve and a barrel cover, wherein the barrel sleeve is fixedly arranged on the top of a paint barrel, and the barrel cover is matched with the barrel sleeve, a strong twisting belt is arranged on the paint barrel, a hand carrying part is fixedly arranged in the middle of the strong twisting belt, a stop block is arranged in the barrel sleeve, a first inclined plane is arranged on the stop block, a second inclined plane matched with the first inclined plane is arranged on the lower end of the barrel cover, and locking grooves are formed in the inner wall of the barrel sleeve in a left and right symmetric arrangement; and a first rotating groove with an upward opening is formed in the middle of the upper end face of the barrel cover, a second rotating groove is formed in the lower end of the first rotating groove, a third rotating groove is formed in the lower end of the second rotating groove, stretching grooves communicating with the outer ends are symmetrically formed in the left side and the right side of the third rotating groove, a rotating plate is rotationally arranged in the third rotating groove, semi-ring grooves are symmetrically formed in the left side and the right side of the rotating plate, arc-shaped grooves are formed in the tail ends of the semi-ring grooves, and a sliding plate is rotatably and arranged in the second rotating groove in an up and down sliding mode.

Owner:江苏汉唐环保科技有限公司

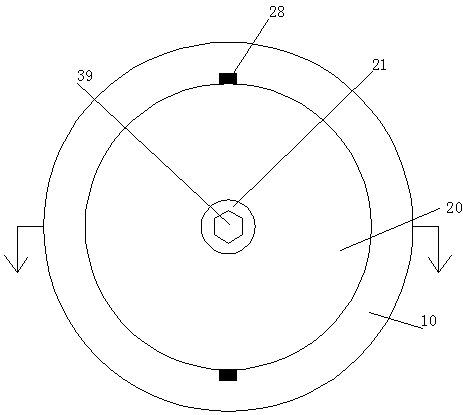

Bridge facility

The invention relate to a bridge facility. The bridge facility comprises a cover sleeve and a sewage cover cooperating with the cover sleeve, wherein fixing rings are correspondingly arranged on the left side and the right side of the cover sleeve; a fixing hole is formed in each fixing ring; a protruding and propping part is arranged in the cover sleeve, and a first oblique propping surface is arranged on the protruding and propping part; a second oblique propping surface cooperating with the first oblique propping surface is arranged at the lower end of the sewage cover; locking grooves arecorrespondingly formed in the left part and the right part of the inner wall of the cover sleeve; a first rotating cavity of which a port faces upwards is formed in the center of the upper end surfaceof the sewage cover; a second rotating cavity is formed in the lower end of the first rotating cavity; a third rotating cavity is formed in the lower end of the second rotating cavity; push grooves which communicate with external ends are correspondingly formed in the left side and the right side of the third rotating cavity; a rotating ring is rotatably mounted in the third rotating cavity; narrow and long grooves are correspondingly formed in the left side and the right side of the rotating ring; a circular cavity is formed in the end tail of each narrow and long groove; and a sliding pushplate is mounted in the second rotating cavity in a manner of capable of circulating and rotating as well as moving up and down.

Owner:NANTONG CHENGXIN MUNICIPAL ENG CO LTD

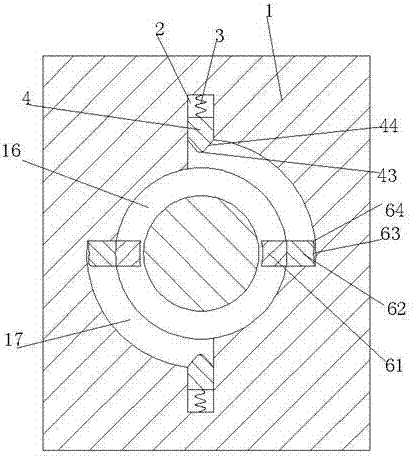

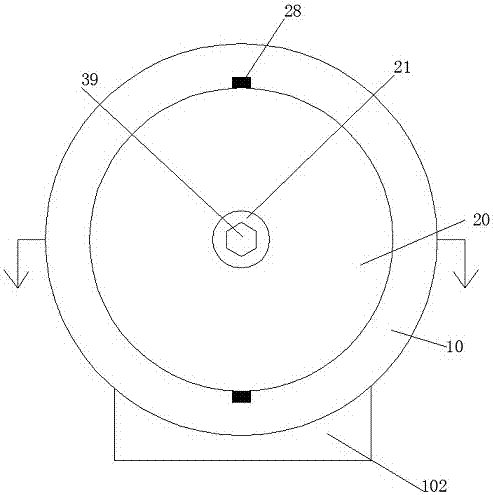

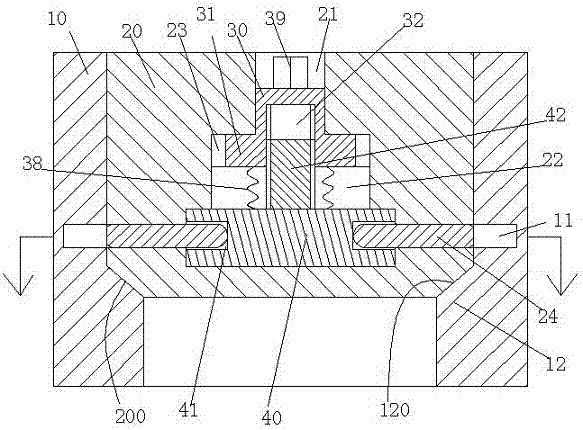

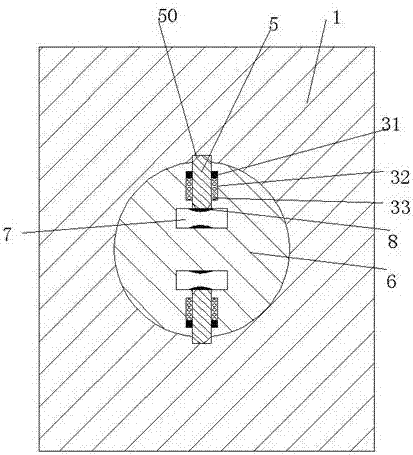

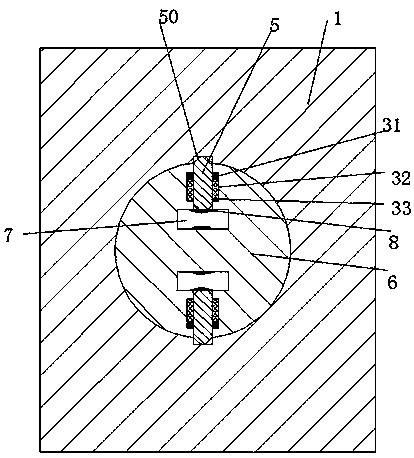

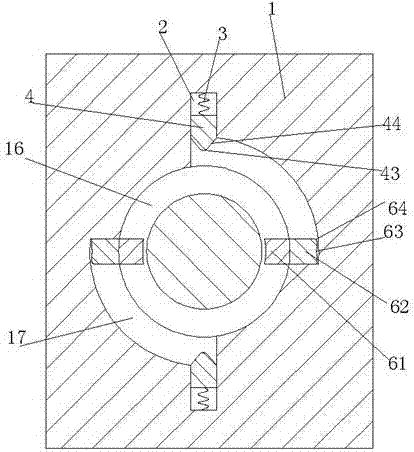

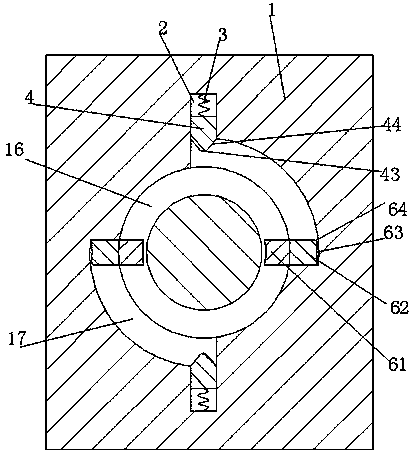

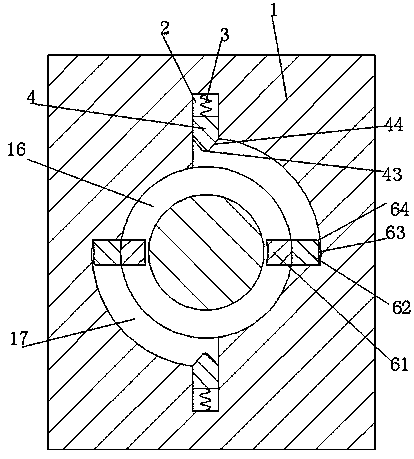

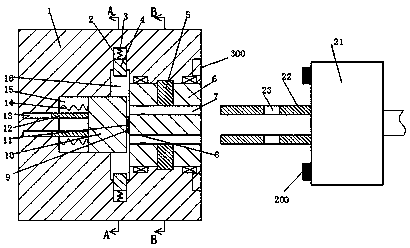

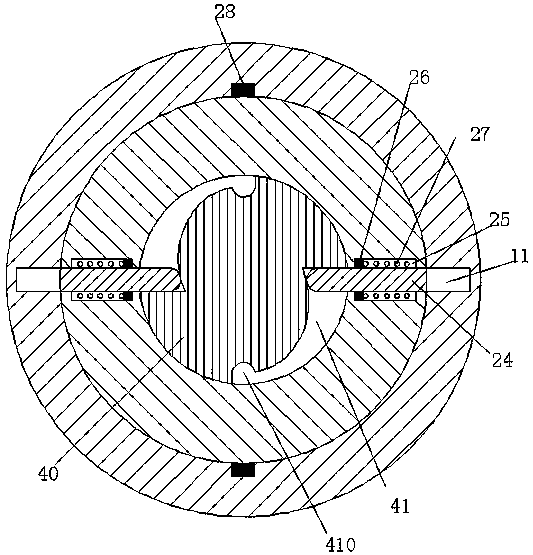

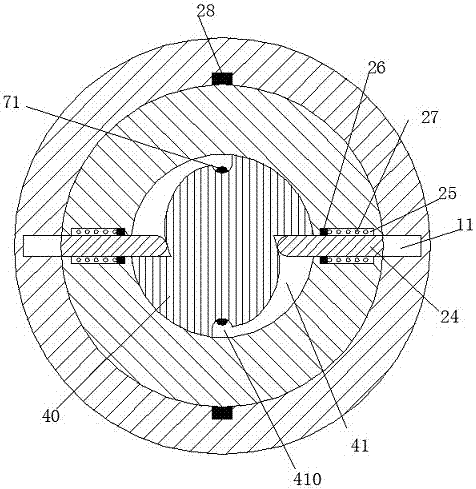

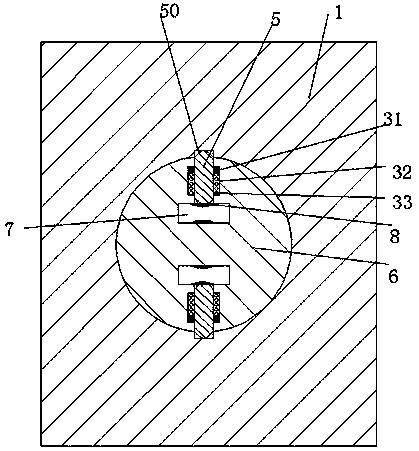

Illuminating lamp device

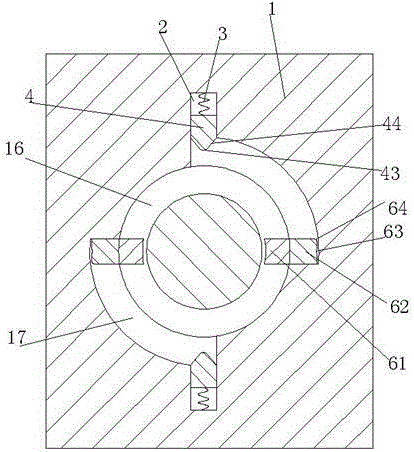

ActiveCN107238022APrevent rotationQuick installationLight fasteningsSemiconductor devices for light sourcesEngineeringMechanical engineering

An illuminating lamp device comprises a lamp holder and a lamp base. A turning hole with a rightward notch is formed in the lamp holder. A turning piece is rotatably mounted in the turning hole. A left insertion groove and a right insertion groove communicating with the left insertion groove are formed in the turning piece in a vertically corresponding mode. Wafers are fixedly mounted in the insertion grooves. A compression sheet is fixedly mounted on the midpoint of the left end face of the turning piece, and a hole is formed in the left end face of the compression sheet. An annular groove is formed in the portion, located at the left end of the turning hole, of the lamp holder, a midpoint groove is formed in the midpoint of the left end of the annular groove, and a horizontal sliding piece is mounted in the midpoint groove and can horizontally slide left and right in the midpoint groove. A fixing pin is fixedly mounted on the midpoint of the right end face of the horizontal sliding piece. A semicircular groove which is located behind and above the horizontal sliding piece and a semicircular groove located in front of and below the horizontal sliding piece are formed in the end wall of the annular groove. Pushing grooves which stretch up and down are arranged in the end wall of the annular groove in a vertically corresponding mode and communicate with the semicircular grooves. Charged sliding blocks are mounted in the pushing grooves in a horizontal sliding mode.

Owner:南通市莱特电气科技发展有限公司

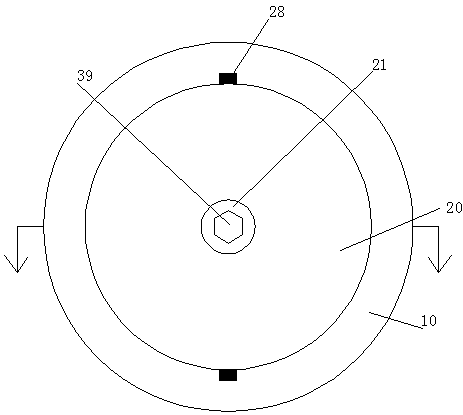

Improved type grinding device

InactiveCN108237477APrevent rotationSimple structurePortable grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

An improved type grinding device comprises an electric connecting seat and an electric connecting head. A torsion hole with a rightward opening portion is formed in the electric connecting seat. A torsion portion is rotationally installed in the torsion hole. Inserting holes penetrating through the torsion portion from left to right are formed in the torsion portion up and down correspondingly. Electric connecting sheets are fixedly installed in the inserting holes. A friction sheet is fixedly installed in the center of the left end surface of the torsion portion, and a round hole is formed inthe left end surface of the friction sheet. The part, located at the left end of the torsion hole, of the electric connecting seat is provided with an annulus groove. A middle groove is formed in thecenter of the left end of the annulus groove. A sliding pushing part is installed in the middle groove in a left-right moving mode. A fixed rod is fixedly installed in the center of the right end surface of the sliding pushing part. Semi-arc grooves located in the rear upper direction and front lower direction of the sliding pushing part are formed in the end wall of the annulus groove. Pushing grooves extending up and down are formed in the upper portion and the lower portion in the end wall of the annulus groove correspondingly and communicate with the semi-arc grooves. Electric connectingblocks are movably installed in the pushing grooves.

Owner:QUZHOU YANHANG MACHINERY TECH CO LTD

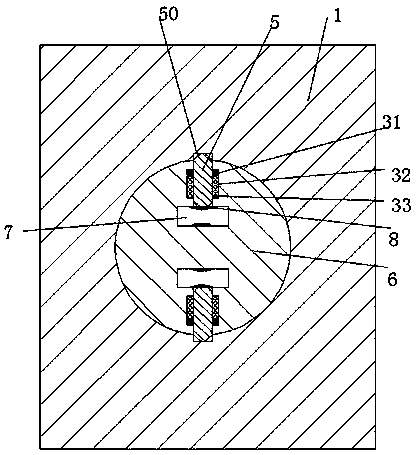

Improved dust remover device

An improved dust remover device comprises a socket and a plug connected with a dust remover, wherein a screwing hole with a rightward open end is formed in the socket; a screwing part is rotatably installed in the screwing hole; plug grooves communicated in a left-right mode are vertically and symmetrically formed in the screwing part; elastic clamping pieces are fixedly installed in the plug grooves; a gasket is fixedly installed at the middle end of the left end face of the screwing part; a hole slot is formed in the left end face of the gasket; an annular groove is formed in the portion, located at the left end of the screwing hole, of the socket; a middle end groove is formed in the middle end position of the left end of the annular groove; a slippage part is installed in the middle end groove in a left-right slippage mode; a plug pin is fixedly installed at the middle end position of the right end face of the slippage part; an arc-shaped groove located above the back of the slippage part and below the front of the slippage part is formed in the end wall of the annular groove; and retracting grooves vertically extending are vertically and symmetrically formed in the end wall ofthe annular groove and are communicated with the arc-shaped groove; and electricity providing blocks are installed in the retracting grooves in a slippage mode.

Owner:方自根

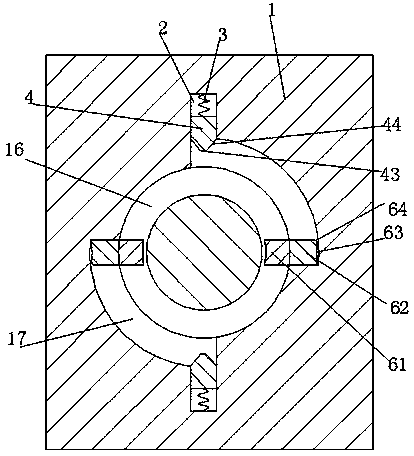

Environment-friendly paint bucket device

ActiveCN107554950ASimple structureEasy to assemble and disassembleRemovable lids/coversLocking devicesSEMI-CIRCLESlide plate

An environment-friendly paint bucket device comprises a bucket sleeve fixedly installed at the top of a paint bucket and a bucket cover matched with the bucket sleeve. A strong twisting belt is arranged on the paint bucket, a handle part is fixedly arranged in the middle of the strong twisting belt, a check block is arranged in the bucket sleeve and provided with a first diagonal plane, a second diagonal plane matched with the first diagonal plane is arranged at the lower end of the bucket cover, and locking grooves are formed in the inner wall of the bucket sleeve in a left-right symmetric mode. A first rotating groove with an upward port is formed in the middle of the upper end face of the bucket cover, a second rotating groove is formed in the lower end of the first rotating groove, a third rotating groove is formed in the lower end of the second rotating groove, stretching grooves communicating with the outer end are symmetrically formed in the left side and the right side of the third rotating groove, a rotating plate is rotationally arranged in the third rotating groove, semi-circle grooves are symmetrically formed in the left side and the right side of the rotating plate, arc grooves are formed in the tail ends of the semi-circle grooves, and a sliding plate is installed in the second rotating groove in a rotatable and vertical sliding mode.

Owner:JIANGSU HANTANG ENVIRONMENTAL PROTECTION TECH CO LTD

Novel mailbox device

Disclosed is a novel mailbox device. The novel mailbox device comprises a mailbox, a sleeve shell and a box cover, wherein the sleeve shell is fixedly arranged at the top of the mailbox, and the box cover is matched with the sleeve shell; the front end surface of the mailbox is provided with a delivery port for putting letters, and a convex eaves plate is fixedly arranged at the front end surface, above the delivery port, of the mailbox; the sleeve shell is internally provided with a convex block, and the convex block is provided with a first bevel surface; the lower end of the box cover is provided with a second bevel surface matched with the first bevel surface; lock grooves are formed in the inner wall of the sleeve shell in a left-right symmetrical mode; the middle of the upper end surface of the box cover is provided with a first transfer groove with an opening facing upwards, the lower end of the first transfer groove is provided with a second transfer groove, the lower end of the second transfer groove is provided with a third transfer groove, retraction grooves communicated with the exterior are symmetrically formed in the left and right sides of the third transfer groove, and a transfer plate is rotatably installed in the third transfer groove.

Owner:聊城来通国际贸易有限公司

A new type of bridge facility

A novel bridge facility comprises a cover bushing and a sewage cover matched with the cover bushing. Fixing rings are arranged on the left and right sides of the cover bushing separately. A fixing hole is arranged in each fixing ring. The cover bushing is internally provided with a convex portion. The convex portion is provided with a first inclined abutting surface. The lower end of the sewage cover is provided with a second inclined abutting surface matched with the first inclined abutting surface. Locking grooves are provided in the inner wall of the cover bushing left and right. A first rotary chamber with an upward opening is arranged in the center of the upper end surface of the sewage cover. A second rotary chamber is arranged in the lower end of the first rotary chamber. A third rotary chamber is arranged in the lower end of the second rotary chamber. Pushing grooves communicating with the outer ends are provided in the left and right sides of the third rotary chamber separately. A rotary ring is rotatably installed in the third rotary chamber. Narrow slots are arranged in the left and right sides of the rotary ring separately. The tail end of each narrow slot is provided with a circular cavity. A sliding pushing plate which can rotate circularly and move up and down is mounted in the second rotary cavity.

Owner:恒泰高新材料科技(南通)有限公司

An improved environment-friendly paint bucket device

Disclosed is an improved environmentally-friendly paint bucket device. The improved environmentally-friendly paint bucket device comprises a bucket sleeve and a bucket cover, wherein the bucket sleeveis fixedly installed on the top of a paint bucket, and the bucket cover is matched with the bucket sleeve. A strong twisting belt is arranged on the paint bucket, and a hand lifting portion is fixedly arranged in the middle of the strong twisting belt. A stop block is arranged in the bucket sleeve, a first diagonal plane is arranged on the stop block, and a second diagonal plane which is matchedwith the first diagonal plane is arranged at the lower end of the bucket cover. Locking grooves are formed in the bucket sleeve in a left-and-right symmetry mode. A first rotating groove with an upward end opening is formed in the middle of the upper end face of the bucket cover, a second rotating groove is formed in the lower end of the first rotating groove, a third rotating groove is formed inthe lower end of the second rotating groove, and stretching grooves which are connected with the outer end are symmetrically formed in the left side and the right side of the third rotating groove. Arotating plate is installed in the third rotating groove in a rotatable mode, semi-ring grooves are symmetrically formed in the left side and the right side of the rotating plate, and arc-shaped grooves are formed in the tail ends of the semi-ring grooves. A sliding plate is installed in the second rotating groove in a rotatable and up-and-down slide mode.

Owner:JIANGSU HANTANG ENVIRONMENTAL PROTECTION TECH CO LTD

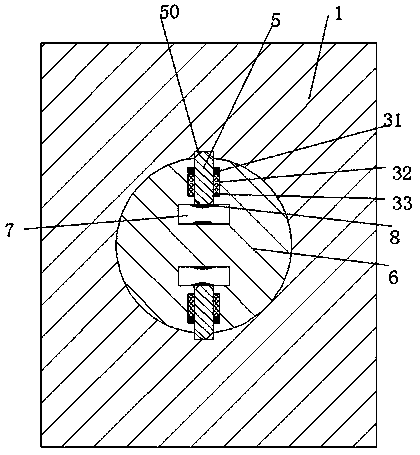

Novel polishing device

InactiveCN108242673APrevent rotationAllow rotationCoupling device detailsMouth partsMechanical engineering

The invention provides a novel polishing device. The novel polishing device comprises an electric connection seat and an electric connector, wherein a twisting hole with a rightward mouth part is formed in the electric connection seat, a twisting part is rotatably mounted in the twisting hole, inserting holes penetrating from left to right are formed in the twisting part correspondingly up and down, and electric connecting pieces are fixedly mounted in each inserting hole; a friction piece is fixedly mounted at the center of a left end face of the twisting part, and a circular hole is formed in a left end face of the friction piece; and an annular slot is formed in a part, located at the left end of the twisting hole, of the electric connection seat, a middle slot is formed in the center of the left end of the annular slot, the middle slot is provided with a sliding component in a left-and-right movable manner, a fixed rod is fixedly mounted at the center of a right end face of the sliding component, semi-arc slots located above the back of the sliding component and located below the front of the sliding component are formed in an end wall of the annular slot, pushing slots extending up and down are formed in the end wall of the annular slot correspondingly up and down, the pushing slots are communicated with the semi-arc slots, and electric connection blocks are movably mounted in the pushing slots.

Owner:QUZHOU YANHANG MACHINERY TECH CO LTD

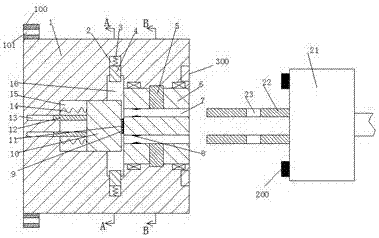

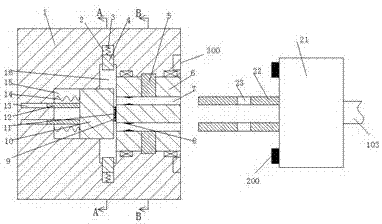

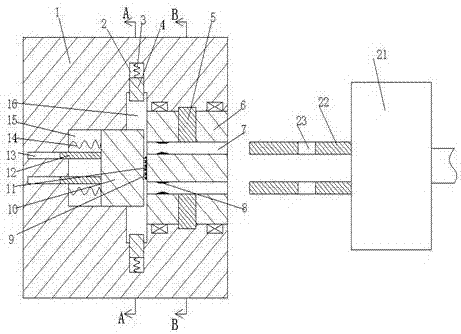

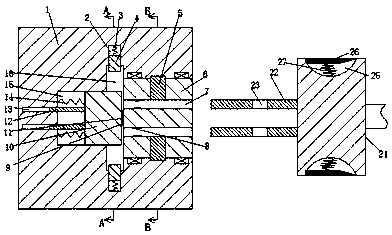

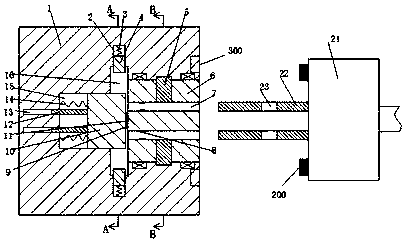

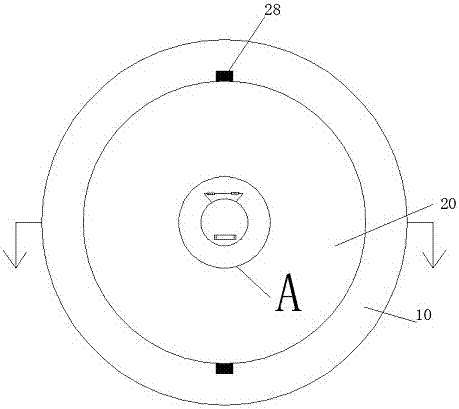

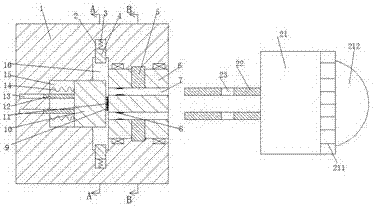

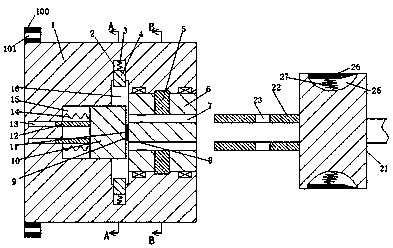

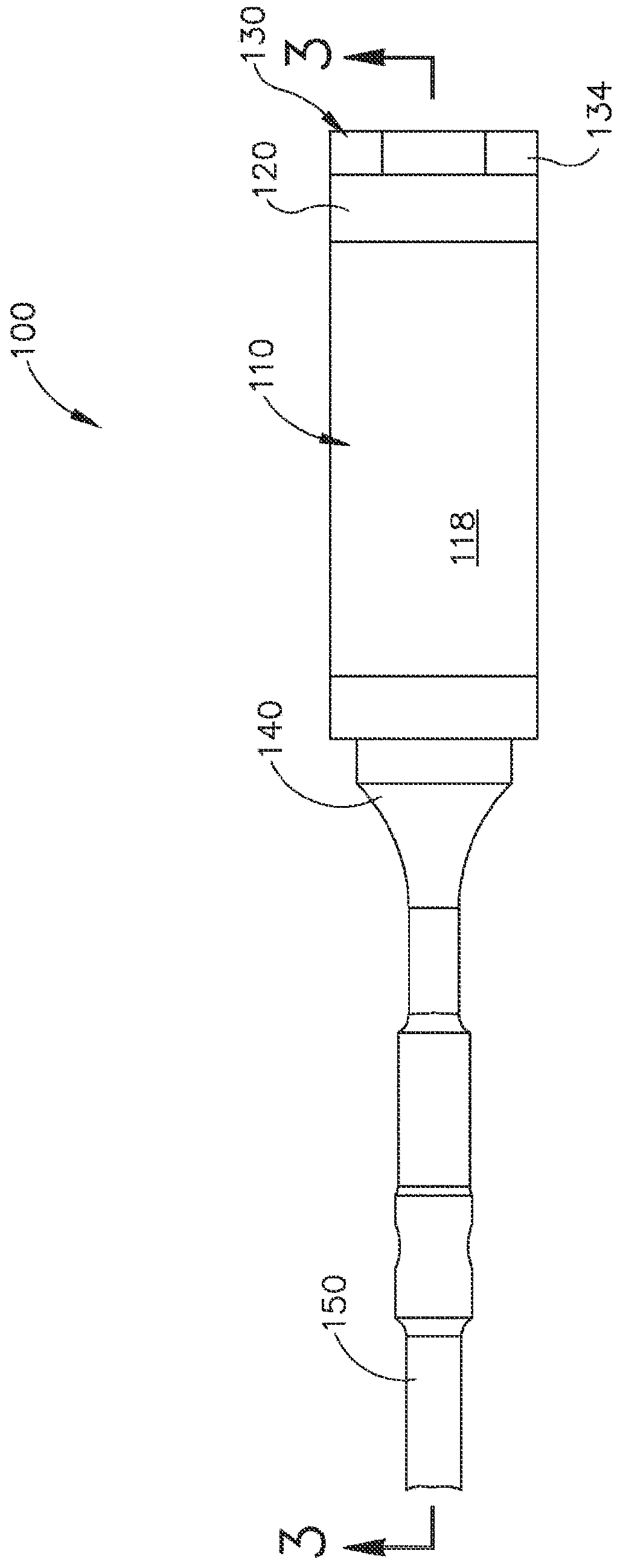

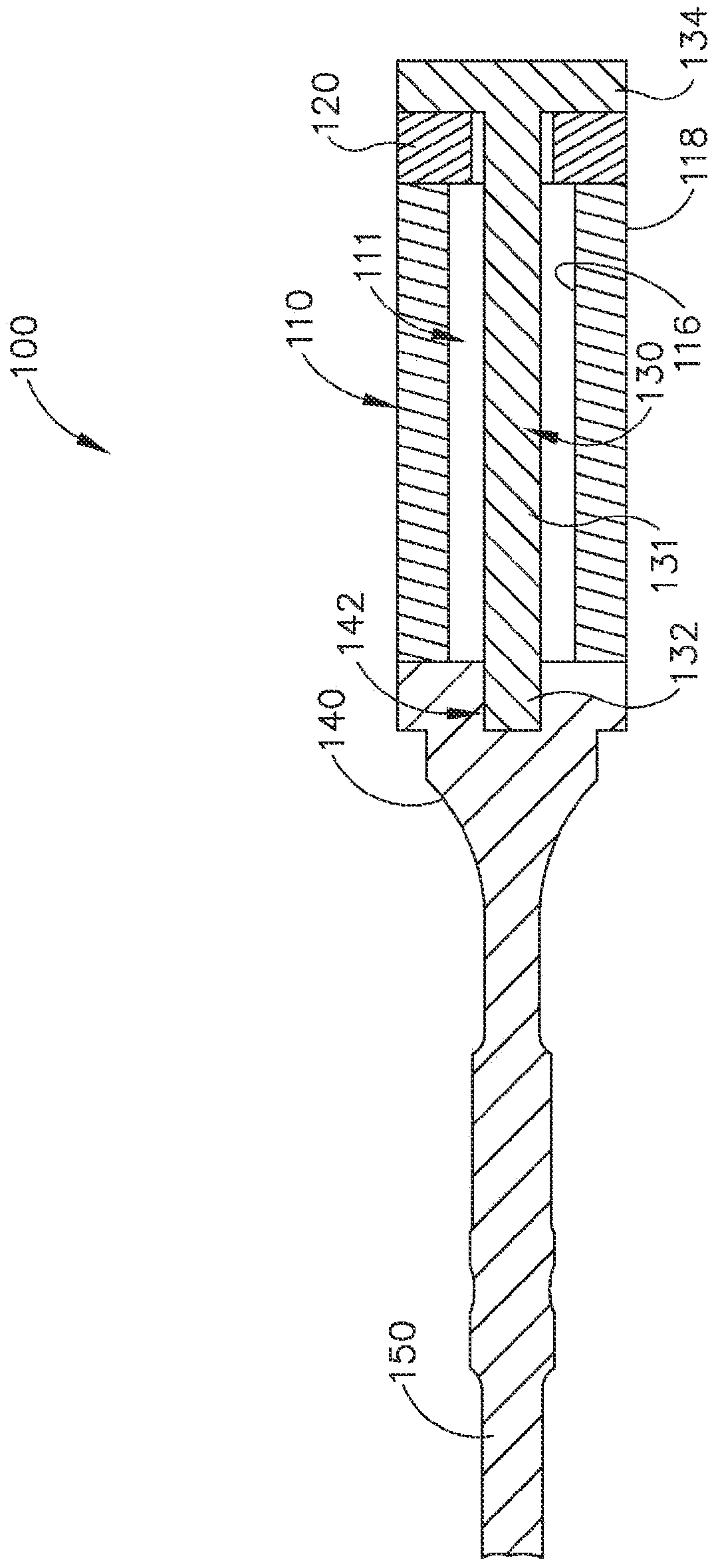

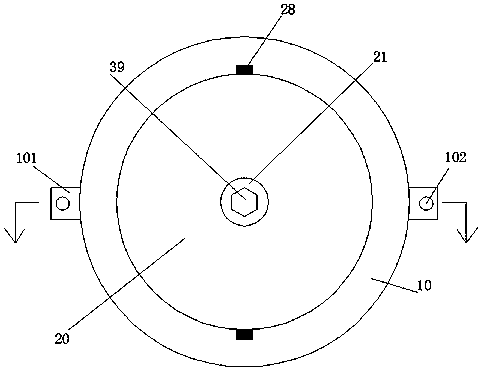

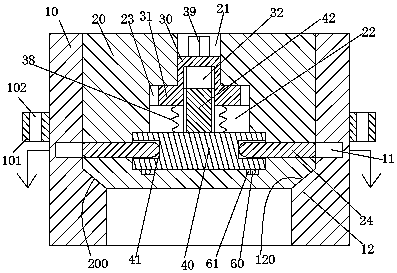

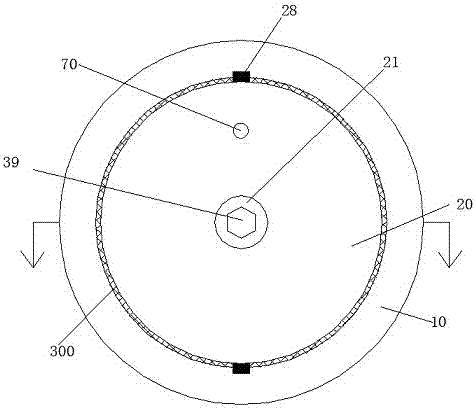

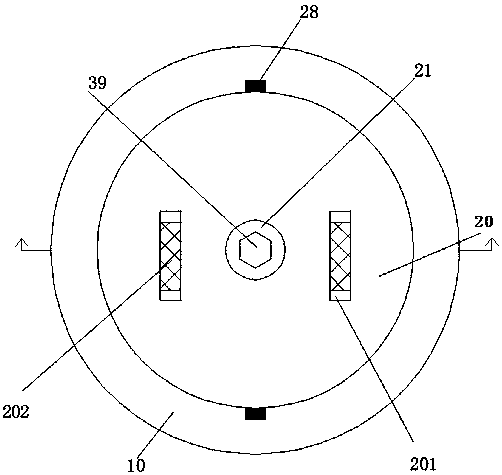

Transducer features for ultrasonic surgical instruments

The invention discloses a device for operating tissue, which includes a main body, a shaft, an ultrasonic knife and an acoustic assembly. The shaft extends distally from the body. The knife is disposed at the distal end of the shaft. The acoustic assembly includes an acoustic waveguide coupled to a blade, a piezoelectric transducer element, a fastener, and a coupling member. The transducer element defines an inner diameter surface and an outer diameter surface. The fastener is configured to secure the transducer element relative to the waveguide. The coupling member is configured to provide electrical continuity between the fastener and the inner diameter surface of the transducer element. The outer diameter surface of the transducer element includes an annular recess. The other coupling member is configured to provide electrical continuity between the annular recess of the piezoelectric transducer element and the power source while allowing the piezoelectric transducer element to rotate relative to the body.

Owner:ETHICON ENDO SURGERY INC

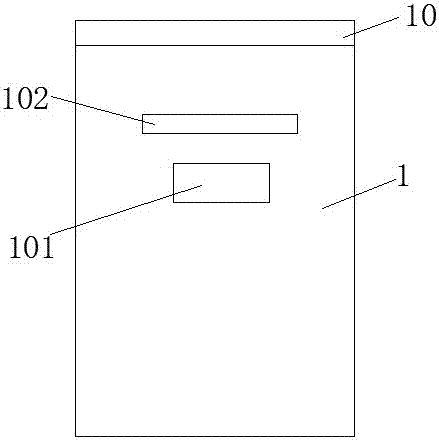

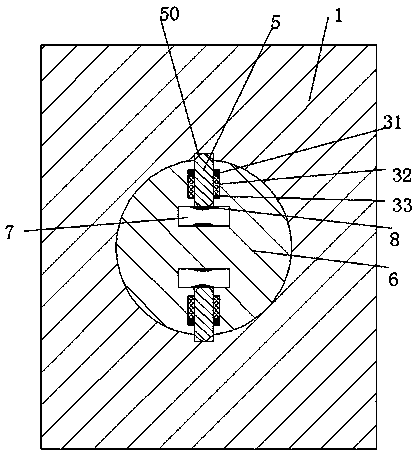

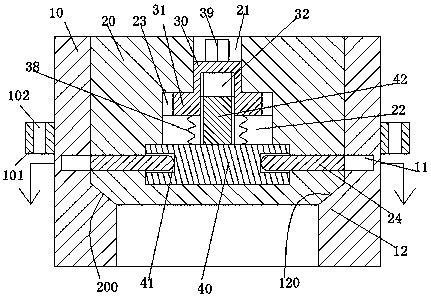

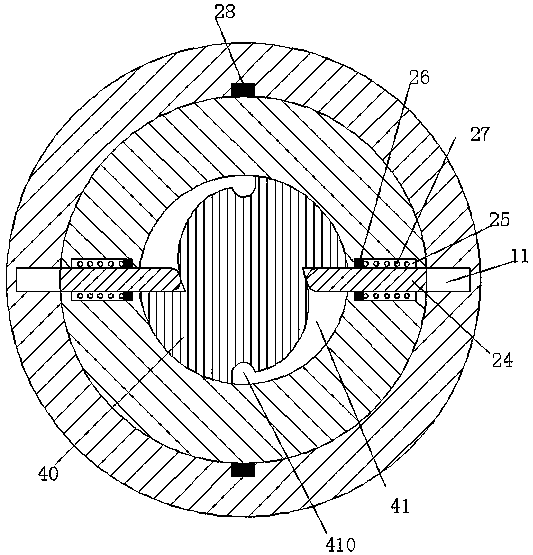

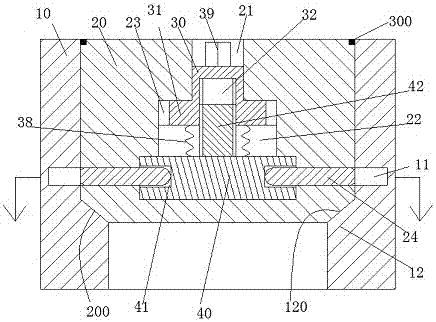

New material device for catalyst support

InactiveCN108380110AAllow rotationAvoid accidental rotationRotating receptacle mixersTransportation and packagingEngineeringNew materials

The invention discloses a new material device for a catalyst support. The new material device comprises a base, a left bearing frame and a right bearing frame, wherein the left bearing frame and the right bearing frame are fixedly mounted on the base; the bottoms of four corners of the base are simultaneously provided with mounting grooves; roller wheels are rotationally mounted in the mounting grooves; a charging barrel is arranged between the left bearing frame and the right bearing frame; a cavity is formed in the charging barrel; the left and right ends of the outer side of the charging barrel are provided with a left rotating rod and a right rotating rod respectively; the left rotating rod and the right rotating rod are rotatablely mounted in the left bearing frame and the right bearing frame respectively; the left rotating rod is connected with a first motor, which is fixedly mounted on the left end surface of the left bearing frame, in a power manner; a uniform agitating shaft which extends in a left-right manner is arranged in the cavity; the left end of the uniform agitating shaft is rotatablely mounted in the left rotating rod; the right end of the uniform agitating shaftis rotatablely mounted in the right rotating rod and is connected with a second motor, which is fixedly mounted on the right end surface of the right bearing frame, in the power manner; the uniform agitating shaft is provided with uniform agitating vanes, and flow guiding pipes which are mutually symmetrical in an up-down manner and are further outwards lengthened are arranged in the charging barrel.

Owner:HUANGSHAN KETAI ENVIRONMENTAL PROTECTION TECH CO LTD

Improved environmentally-friendly paint bucket device

ActiveCN107554966ASimple structureEasy to assemble and disassembleLocking devicesSlide plateEngineering

Disclosed is an improved environmentally-friendly paint bucket device. The improved environmentally-friendly paint bucket device comprises a bucket sleeve and a bucket cover, wherein the bucket sleeveis fixedly installed on the top of a paint bucket, and the bucket cover is matched with the bucket sleeve. A strong twisting belt is arranged on the paint bucket, and a hand lifting portion is fixedly arranged in the middle of the strong twisting belt. A stop block is arranged in the bucket sleeve, a first diagonal plane is arranged on the stop block, and a second diagonal plane which is matchedwith the first diagonal plane is arranged at the lower end of the bucket cover. Locking grooves are formed in the bucket sleeve in a left-and-right symmetry mode. A first rotating groove with an upward end opening is formed in the middle of the upper end face of the bucket cover, a second rotating groove is formed in the lower end of the first rotating groove, a third rotating groove is formed inthe lower end of the second rotating groove, and stretching grooves which are connected with the outer end are symmetrically formed in the left side and the right side of the third rotating groove. Arotating plate is installed in the third rotating groove in a rotatable mode, semi-ring grooves are symmetrically formed in the left side and the right side of the rotating plate, and arc-shaped grooves are formed in the tail ends of the semi-ring grooves. A sliding plate is installed in the second rotating groove in a rotatable and up-and-down slide mode.

Owner:江苏汉唐环保科技有限公司

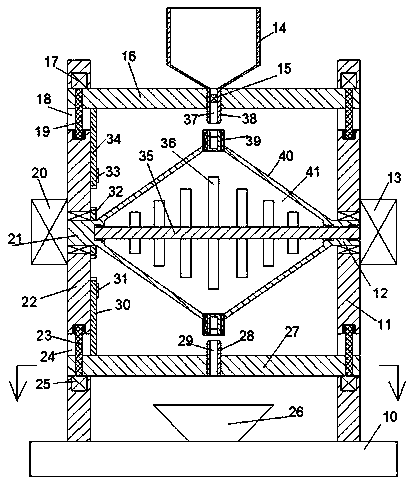

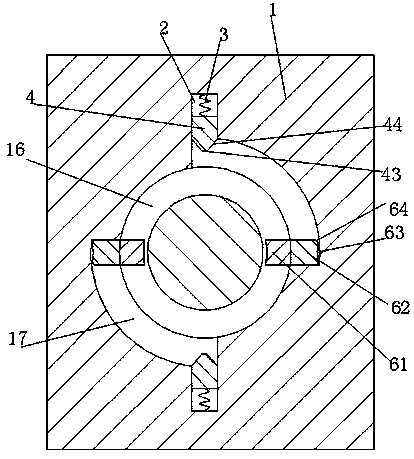

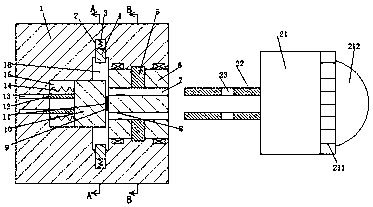

Mould comprising mobile elements which are obtained by sintering

ActiveCN106660282AAllow rotationEasy to demouldAdditive manufacturing apparatusTyresMaterials science

Owner:OCIETE DE TECH MICHELIN

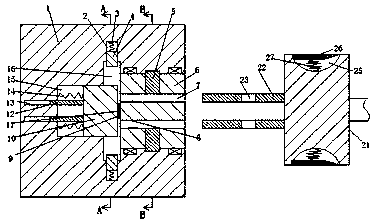

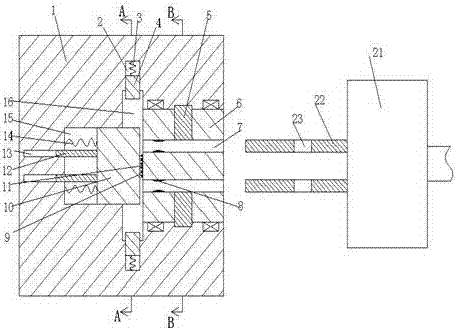

Welding device

InactiveCN107253002APrevent rotationSimple structureWelding/cutting auxillary devicesAuxillary welding devicesElectricityEngineering

Provided is a welding device. The welding device comprises a distribution box and an electric connecting head which is connected with a welding machine. At least more than one group of electric connecting bases is arranged in the distribution box and is separated up and down through separation plates. Transferring holes with rightward through openings are formed in the electric connecting bases, and transferring pieces are rotatably installed in the transferring holes. Left-and-right intercommunicated plugging grooves are formed in the transferring pieces equivalently up and down, and electric connecting pieces are fixedly installed in the plugging grooves. Wear-proof pieces are fixedly installed in the middles of the left end faces of the transferring pieces, and empty holes are formed in the left end faces of the wear-proof pieces. Ring connecting grooves are formed in the part, located at the left ends of the transferring holes, of the electric connecting bases. Middle grooves are formed in the middles of the left ends of the ring connecting grooves. Sliding connecting pieces capable of sliding left and right are installed in the middle grooves. Plug pins are fixedly installed in the middles of the right end faces of the sliding connecting pieces. Crescent grooves located in the rear parts above the sliding connecting pieces and located in the front parts below the sliding connecting pieces are formed in the end walls of the ring connecting grooves. Pushing grooves extending up and down are formed in the end walls of the ring connecting grooves equivalently up and down. The pushing grooves communicate with the crescent grooves, and electricity connecting blocks are installed in the pushing grooves in a sliding connecting mode.

Owner:何华勇

Improved bridge facility

ActiveCN107558498AAvoid lossReduce security risksArtificial islandsUnderwater structuresEngineeringSewage

The invention discloses an improved bridge facility. The improved bridge facility comprises a cover sleeve and a sewage cover matched with the cover sleeve. Fixing rings are arranged on the left sideand the right side of the cover sleeve correspondingly. A fixing hole is formed in each fixing ring. A protruding abutting portion is arranged in the cover sleeve. A first slant abutting face is arranged on the protruding abutting portion. A second slant abutting face matched with the first slant abutting face is arranged at the lower end of the sewage cover. Locking grooves are formed in the inner wall of the cover sleeve correspondingly in the left and right direction. A first rotating chamber with an upward through opening is formed in the center of the upper end face of the sewage cover. Asecond rotating chamber is arranged at the lower end of the first rotating chamber. A third rotating chamber is arranged at the lower end of the second rotating chamber. Each of the left side and theright side of the third rotating chamber is provided with a pushing groove communicating with the corresponding outer end of the third rotating chamber. A rotating ring is rotationally installed in the third rotating chamber. Slots are correspondingly formed in the left side and the right side of the rotating ring. A circular chamber is formed in the tail end of each slot. A sliding pushing plateis installed in the second rotating chamber in a rotational and vertically movable manner.

Owner:NANTONG CHENGXIN MUNICIPAL ENG CO LTD

A lighting device

ActiveCN107238022BPrevent rotationAllow rotationLight fasteningsSemiconductor devices for light sourcesLight headMechanical engineering

An illuminating lamp device comprises a lamp holder and a lamp base. A turning hole with a rightward notch is formed in the lamp holder. A turning piece is rotatably mounted in the turning hole. A left insertion groove and a right insertion groove communicating with the left insertion groove are formed in the turning piece in a vertically corresponding mode. Wafers are fixedly mounted in the insertion grooves. A compression sheet is fixedly mounted on the midpoint of the left end face of the turning piece, and a hole is formed in the left end face of the compression sheet. An annular groove is formed in the portion, located at the left end of the turning hole, of the lamp holder, a midpoint groove is formed in the midpoint of the left end of the annular groove, and a horizontal sliding piece is mounted in the midpoint groove and can horizontally slide left and right in the midpoint groove. A fixing pin is fixedly mounted on the midpoint of the right end face of the horizontal sliding piece. A semicircular groove which is located behind and above the horizontal sliding piece and a semicircular groove located in front of and below the horizontal sliding piece are formed in the end wall of the annular groove. Pushing grooves which stretch up and down are arranged in the end wall of the annular groove in a vertically corresponding mode and communicate with the semicircular grooves. Charged sliding blocks are mounted in the pushing grooves in a horizontal sliding mode.

Owner:南通市莱特电气科技发展有限公司

Improved intelligent robot equipment

InactiveCN107511850ASimple structureEasy to assemble and disassembleManipulatorSlide plateEngineering

Improved intelligent robot equipment comprises an overhauling port fixedly arranged in a robot body and an overhauling cover matched with the overhauling port. An ejector block is arranged in the overhauling port and provided with a first slope face. A second slope face matched with the first slope face is arranged at the lower end of the overhauling cover. Locking and fixing grooves are formed in the inner wall of the overhauling port in a left-and-right symmetry manner. A first rotation hole with an upward sloth is formed in the middle end position of the upper end face of the overhauling cover. A second rotation hole is formed in the lower end of the first rotation hole. A third rotation hole is formed in the lower end of the second rotation hole. Shrinkage grooves communicating with the outer end are symmetrically formed in the left side and the right side of the third rotation hole, the third rotation hole is internally and rotationally provided with a rotary disc, and semicircular grooves are symmetrically formed in the left side and the right side of the rotary disc. Circular holes are formed in the tail portions of the semicircular grooves, and a sliding plate is arranged in the second rotation hole in a rotating and up-down sliding manner.

Owner:黄贤水

Improved electricity utilization plugging component

An improved electricity utilization plugging component comprises a bayonet socket fixedly arranged in a wall and a connecting plug connected to electric equipment. The bayonet socket is provided witha rotation hole whose opening faces towards the right. The rotation hole is rotatably provided with a rotation component. The rotation component is vertically and symmetrically provided with plug grooves connected to left and right portions. Elastic conducting strips are fixedly installed in the plug grooves. A center of a left end surface of the rotation component is fixedly provided with a rubber sheet. A left end surface of the rubber sheet is provided with a concave hole. A left end of the bayonet socket, which is located at the rotation hole, is provided with a circular groove. A center of a left end of the circular groove is provided with a center groove. A slide component which can slide horizontally is installed in the center groove. A center of a right end surface of the slide component is fixedly provided with a pin. An end wall of the circular groove is provided with arc rotation grooves which are located in an upper portion behind the slide component and in a lower portionin front of the slide component. The end wall of the circular groove is vertically and symmetrically provided with telescopic grooves which are extended vertically. The telescopic grooves are connected to the arc rotation grooves. Power supply blocks are slidingly arranged in the telescopic grooves.

Owner:徐学铖

A new energy vehicle device

ActiveCN107554624BAllow rotationPrevent rotationSuperstructure subunitsVehicle servicing/repairingNew energySlide plate

The invention relate to a new energy vehicle device. The new energy vehicle device comprises a repairing and checking opening fixedly mounted in a vehicle cabin and a repairing and checking cover cooperating with the repairing and checking opening, wherein a convex part is arranged in the repairing and checking opening; a first oblique sliding surface is arranged on the convex part; a second oblique sliding surface cooperating with the first oblique sliding surface is arranged at the lower end of the repairing and checking cover; locking and supporting grooves are correspondingly formed in theleft part and the right part of the inner wall of the repairing and checking opening; a first rotating bin of which an opening end faces upwards is arranged in the center of the upper end surface ofthe repairing and checking cover; a second rotating bin is arranged at the lower end of the first rotating bin; a third rotating bin is arranged at the lower end of the second rotating bin; pushing and propping grooves which communicate with external ends are correspondingly formed in the left side and the right side of the third rotating bin; a steering plate is rotatably mounted in the third rotating bin; crescent grooves are correspondingly formed in the left side and the right side of the steering plate; a spheroidal groove is formed in the end tail of each crescent groove; and a sliding plate is mounted in the second rotating bin in a manner of capable of steering and sliding up and down smoothly.

Owner:WM MOTOR TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com