Improved type grinding device

An improved, electric connection technology, applied in the direction of grinding/polishing safety devices, grinding machines, portable grinding beds, etc., can solve problems such as unstable locking mode, inconvenient grinding work, loose plugging, etc., to improve power supply safety, Improve the stability of plugging and prevent loosening of plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

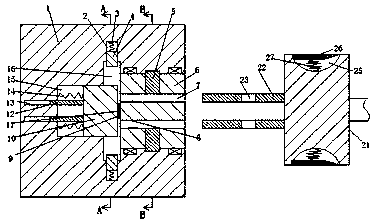

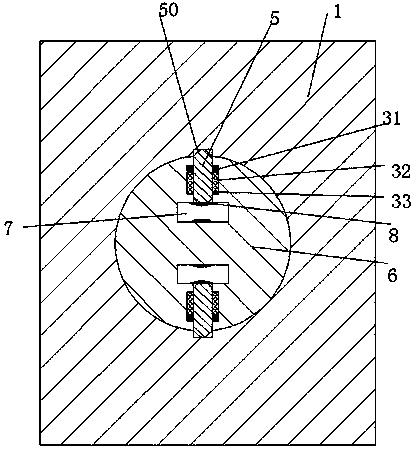

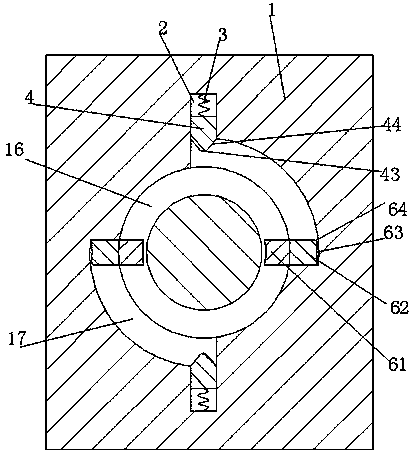

[0027] Combine below Figure 1-7 The present invention will be described in detail.

[0028] refer to Figure 1-7 , an improved grinding device according to an embodiment of the present invention, including an electrical connector and an electrical connector 21, the left end surface of the electrical connector 1 is fixed with a fixed shaft 100, and the fixed shaft 100 is up and down. A plurality of sets of fixing screw holes 101 are equidistant in the direction, and the fixing shaft 100 is used for fixing the electrical connector 1. The electrical connector 1 is provided with a twist hole with the mouth facing right, and A torsion part 6 is rotatably installed, and the upper and lower sides of the torsion part 6 are correspondingly provided with sockets 7 connected to the left and right, and an electrical connecting piece 8 is fixedly installed in the socket 7, and the center of the left end surface of the torsion part 6 is fixed A friction piece 11 is installed, and the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com