Injector reducing residual volume of liquid medicine

A syringe and residual volume technology, applied in the field of medical tools, can solve the problems of inaccurate dose of injected drugs, reduced drug efficacy, residual drug volume, etc., and achieve the effects of ensuring drug efficacy and efficacy, reducing patient costs, and eliminating drug waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

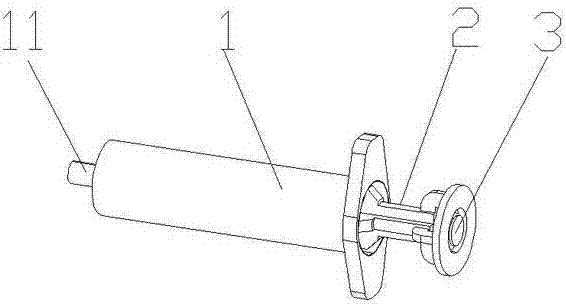

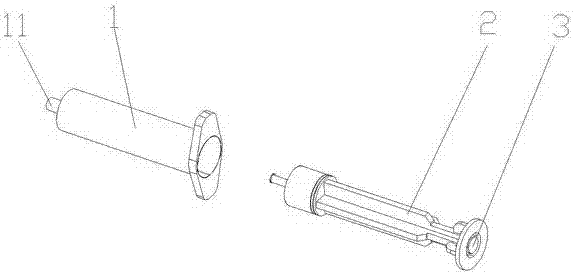

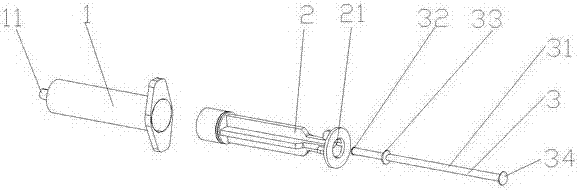

[0016] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a syringe for reducing the residual amount of liquid medicine comprises an empty syringe barrel 1 and an injection piston 2. The empty syringe barrel 1 has a nipple 11, and the injection piston 2 is arranged in the empty syringe barrel 1. It is characterized in that: the injection The inside of the piston 2 has a through hole 21, and the front end of the injection piston 2 has a return spring. The residual medicine piston 3 is arranged in the through hole 21 of the injection piston 2, and is sealed and matched with the through hole 21. The residual medicine piston 3 includes a piston rod 31, a sealing Washer 32, spring retaining ring 33 and push plate 34, sealing washer 32 and spring retaining ring 33 are respectively fixedly arranged on the front end of piston rod 31, push plate 34 is fixedly arranged on the rear end of piston rod 31, and sealing washer 32 cooperates with nipple 11, The spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com