Replacing and sampling device for honeycomb-type denitrification catalyst

A denitrification catalyst and sampling device technology, which is applied in the field of honeycomb denitrification catalyst replacement and sampling devices, can solve the problems of being unable to take out, drop, and easy to loosen, and achieve the effect of simple and practical device, preventing loosening, and reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

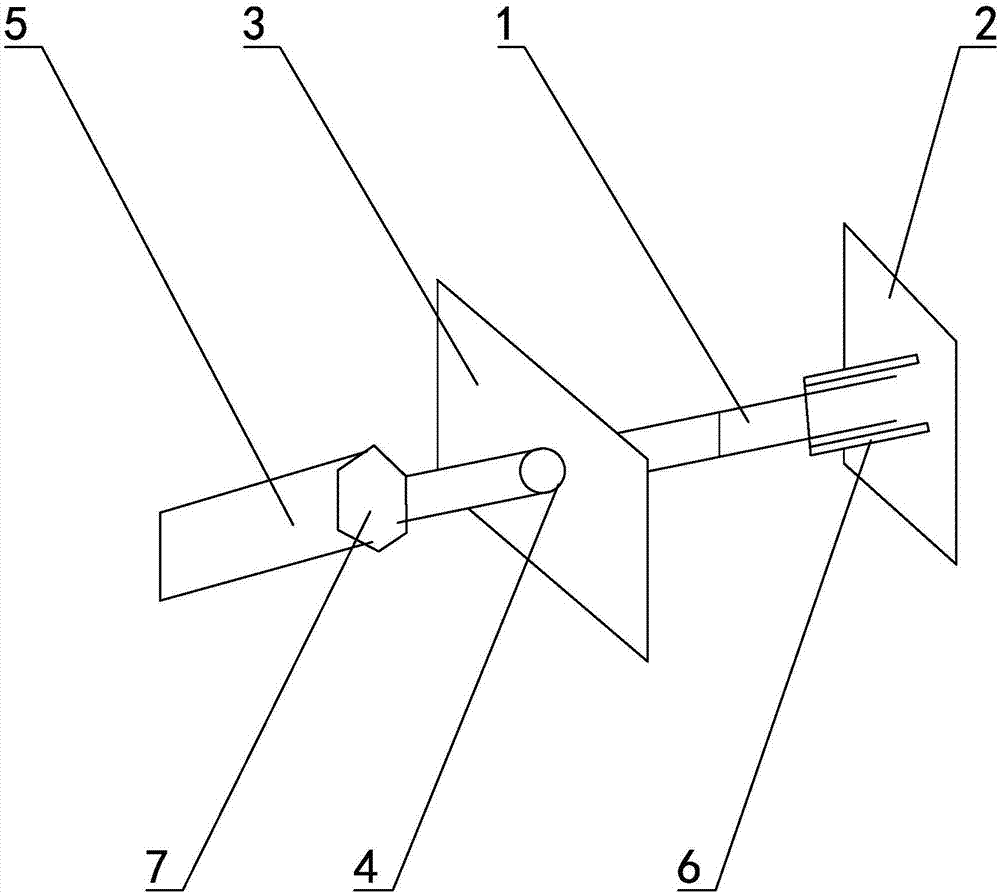

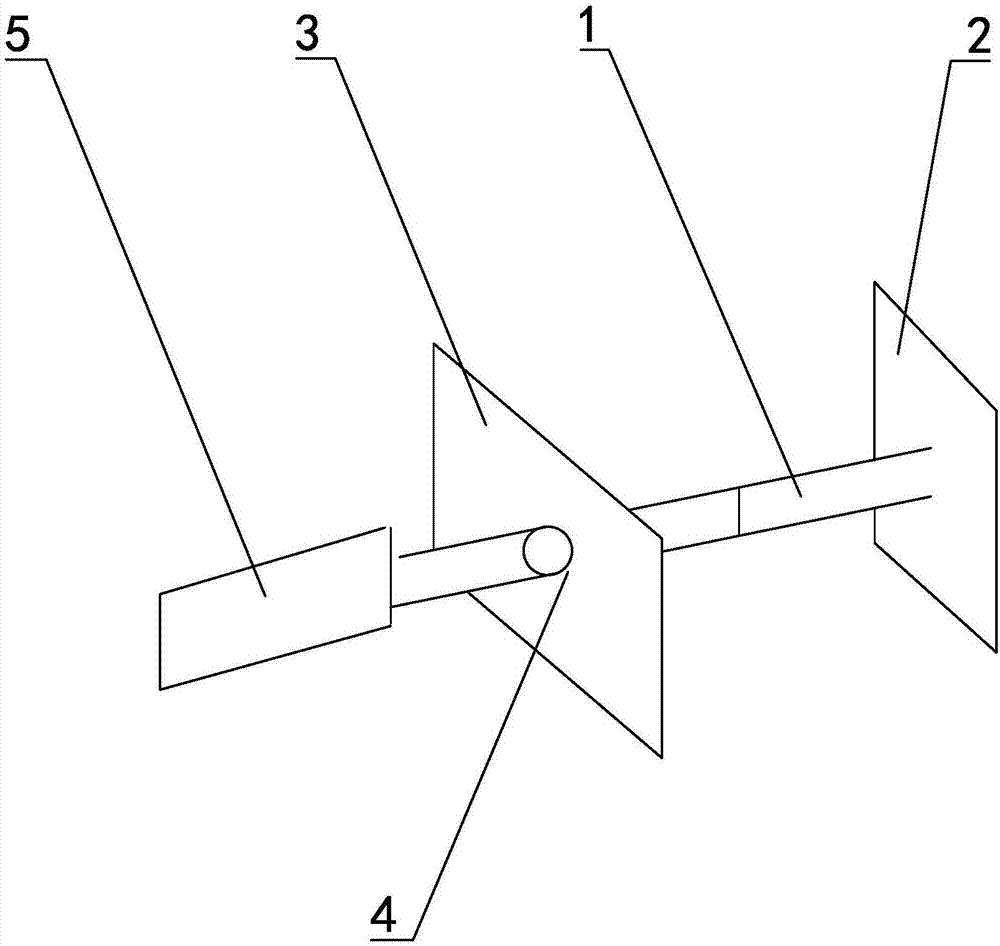

[0020] Such as figure 1 Shown is Embodiment 1 of the present invention: a honeycomb denitration catalyst replacement and sampling device, including a plurality of unit body action components acting on the catalyst module, and the unit body action components act on the unit body to be ejected or the unit to be ejected The unit body around the body, the unit body action components include a transmission shaft 1, a support plate 2 and a fastener 3, the fastener 3 is installed on the outer bracket of the catalyst module, the fastener 3 is provided with a limit hole 4, and the transmission shaft 1 is connected to the fastener 3 through the limiting hole 4, one end of the transmission shaft 1 passes through the limiting hole 4 and acts on the support plate 2, and the other end of the transmission shaft 1 is connected to the power device 5.

[0021] The limit hole 4 is provided with an internal thread, the transmission shaft 1 is provided with an external thread, and the limit hole 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com