Progressive die and feeding device thereof

A technology of feeding device and concave die, applied in the field of continuous die, can solve the problems of die wear, etc., and achieve the effect of protecting the strip and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

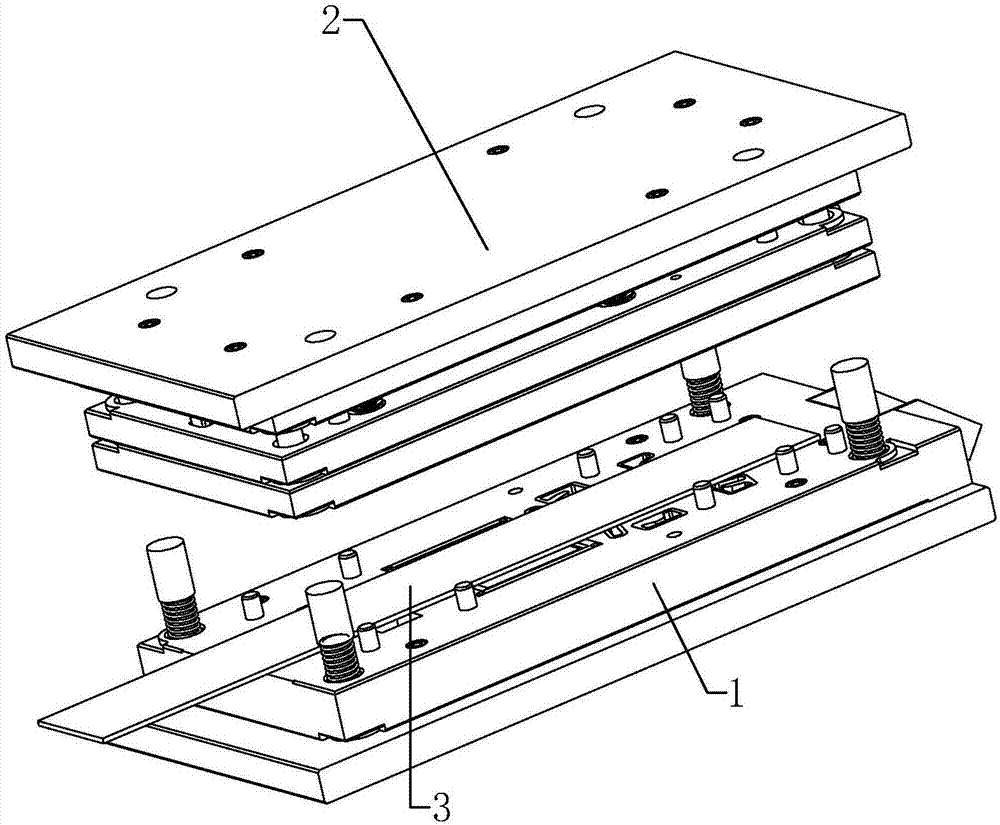

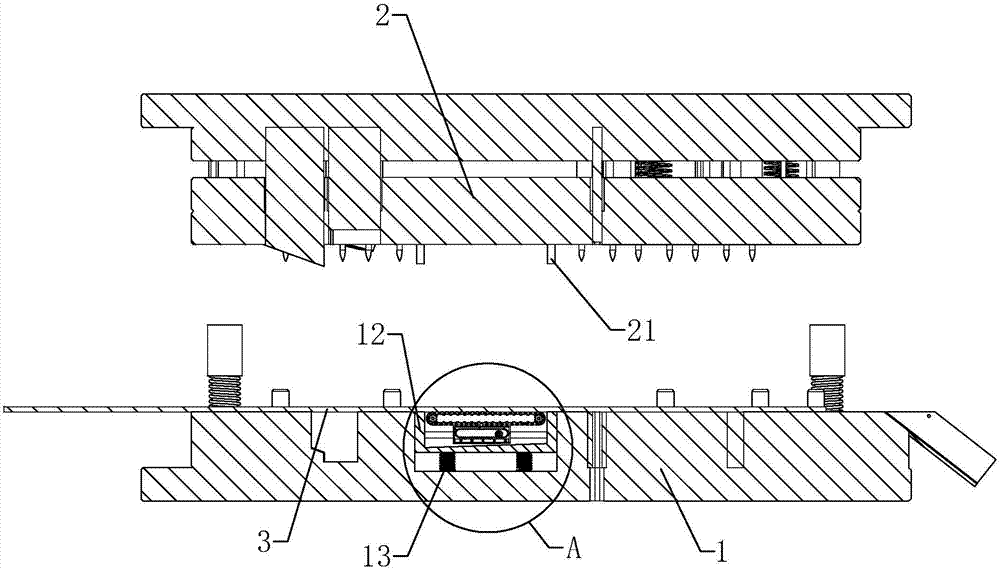

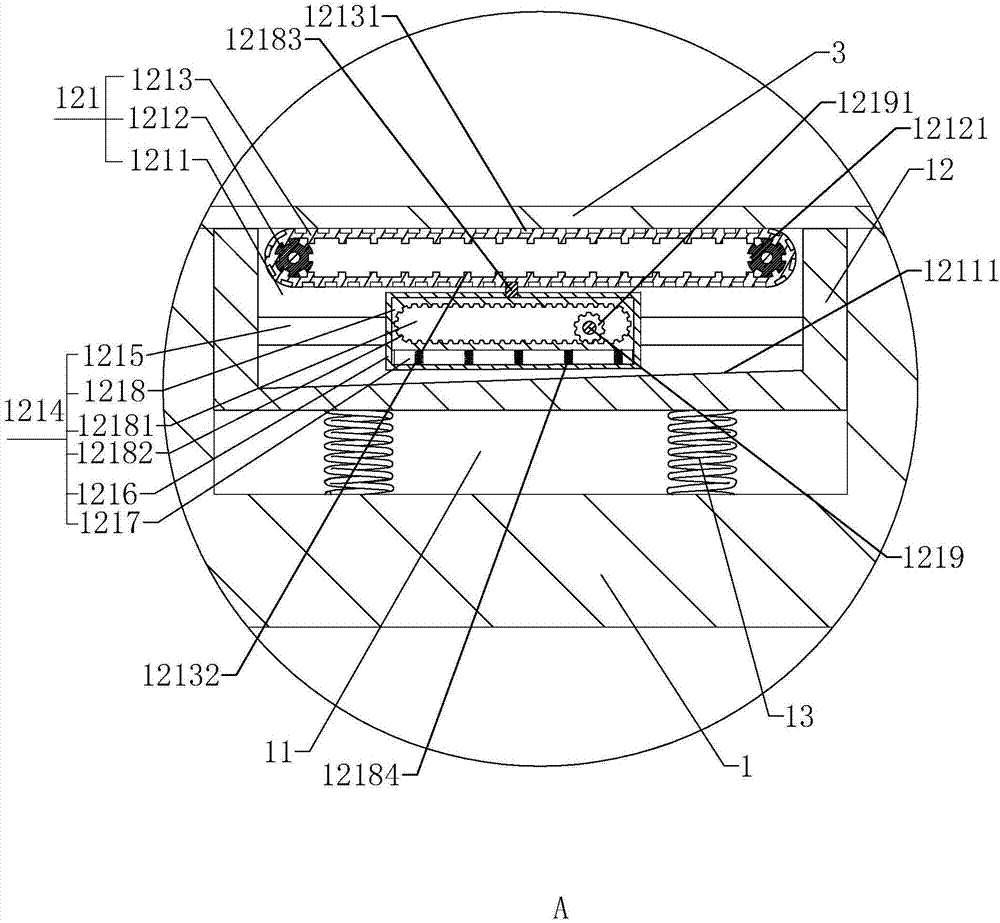

[0039] A continuous mold feeding device, such as figure 1 , including the moving slots 11 opened between the dies of the lower die 1 (such as figure 2 ), sliding the moving block 12 connected in the moving groove 11 along the vertical direction (such as image 3 ), a number of first compression springs 13 arranged between the moving block 12 and the bottom of the moving groove 11, and a push rod 21 corresponding to the moving block 12 arranged on the upper die 2 (such as figure 2 ), and the moving block 12 is provided with a guide hole 124 for the insertion of the ejector rod 21 (such as Figure 5 ).

[0040] Such as figure 2 , when the first compression spring 13 is in the original state, the upper end of the moving block 12 extends out of the notch of the moving groove 11 and the material strip 3 at the upper end of the moving block 12 is located at the upper end of each die, that is, there is a gap between the material strip 3 and the die, At this moment, upper mold ...

Embodiment 2

[0047] Embodiment 2: A kind of continuous die, comprises upper die 2, lower die 1 and above-mentioned embodiment 1, feeding device sends material strip 3 into each station step by step, reduces the friction between material strip 3 and each die, Then the material strip 3 is protected, and the product quality is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com