Fan spot welding fixture

A spot welding and fixture technology, used in welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of unstable welding quality of fan blades, low welding efficiency, and low degree of automation, so as to improve the degree of automation and production efficiency, The effect of reducing labor costs and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

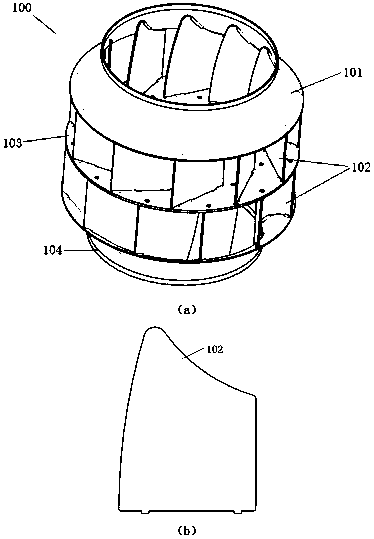

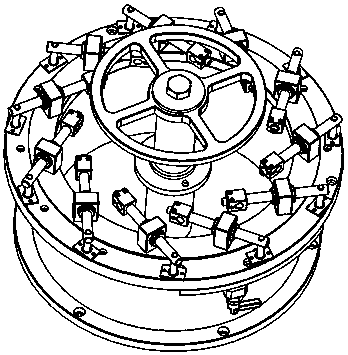

[0028] Such as Figure 1-10 As shown, the fan spot welding fixture of the present invention includes a base assembly and a central axis assembly;

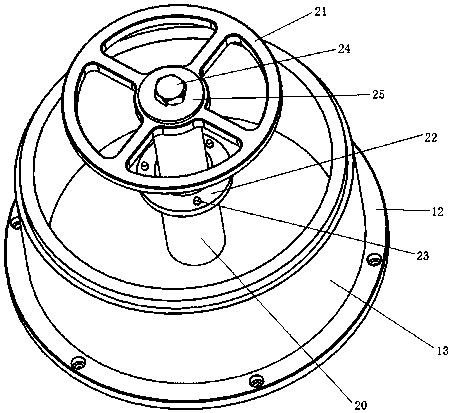

[0029] The base assembly is welded by a round bottom plate 12 and a cylinder 13;

[0030] The central shaft assembly includes a central shaft 20 and a cover ring 21. The bottom of the central shaft 20 is vertically welded on the round bottom plate 12, and the cover ring 21 is detachably fixed on the top of the central shaft 20, such as by a combination of a washer 25 and a screw 24. , the middle part of the central axis 20 is fixed with a partition support plate 22, and a plurality of positioning pins 23 protruding from the upper surface of the partition support plate 22 are uniformly provided on the partition support plate 22;

[0031] An inner ring 1 is fixed on the upper edge of the cylinder 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com