Detection and protection assembly for machine tool protective cover

A protective cover and component technology, applied in the direction of maintenance and safety accessories, metal processing machinery parts, measuring/indicating equipment, etc., can solve the problems of detachable fixed protection not installed or not installed, not easy to disassemble, not detachable, etc., to achieve The structure is simple, easy to realize, and the effect of reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

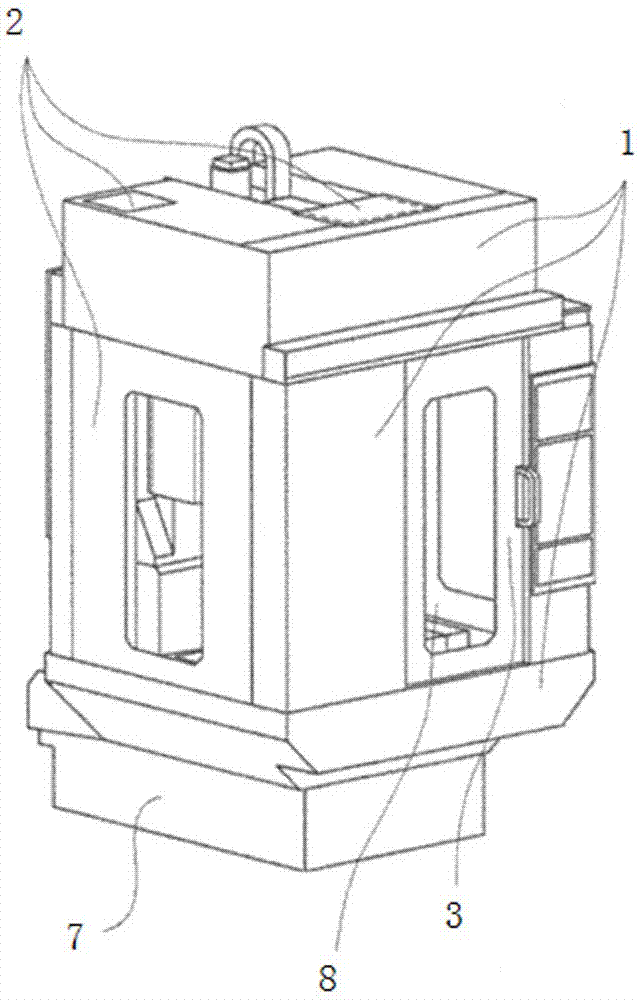

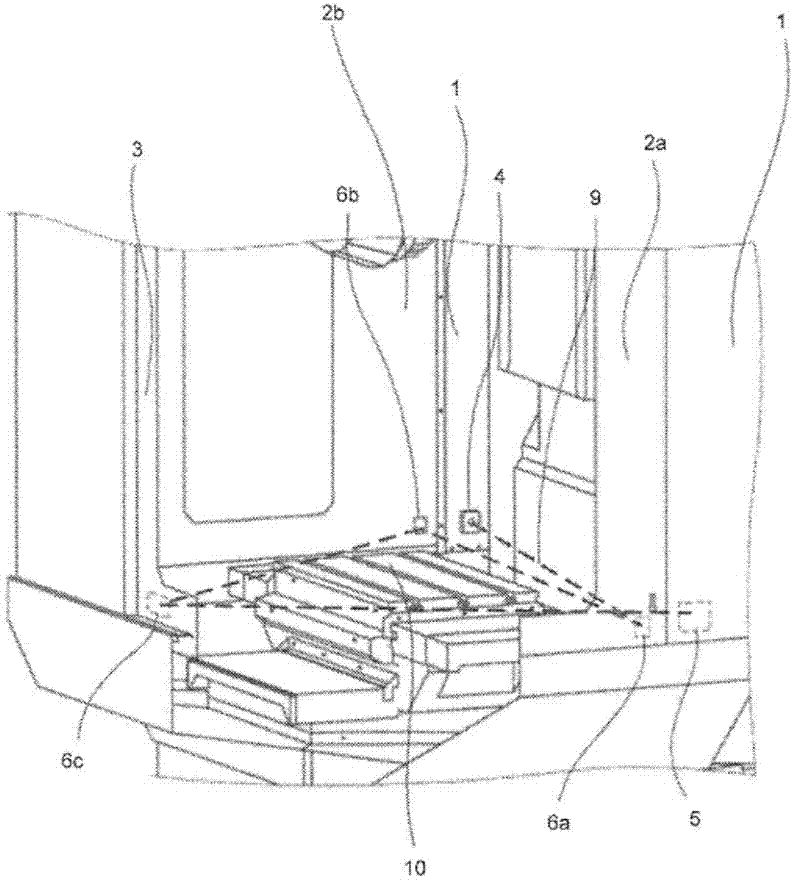

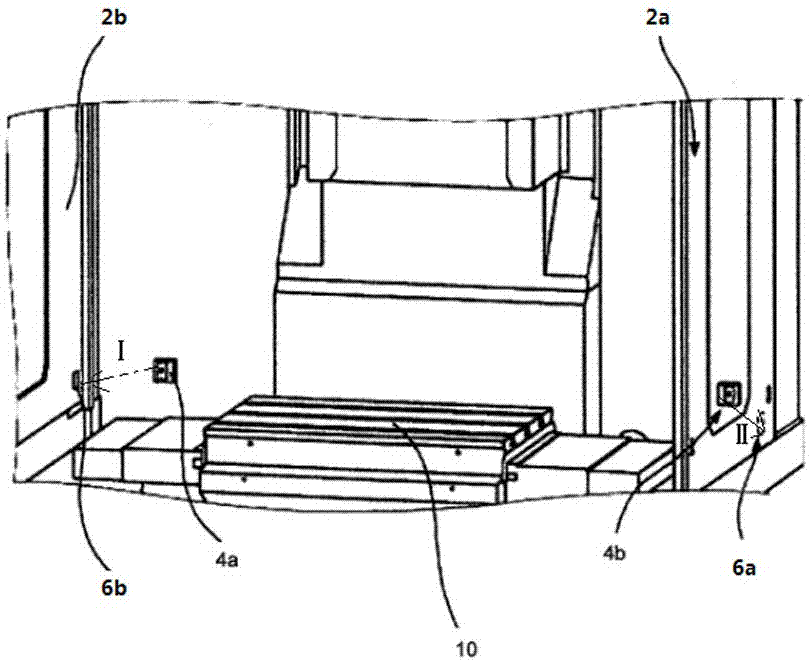

[0025] According to the first embodiment of the present invention, figure 1 It is an isometric view of a machine tool and a protective cover according to the first embodiment of the present invention, figure 2 It is a schematic diagram of the detection and protection assembly installation of the first embodiment of the present invention, refer to figure 1 and figure 2 As shown, the machine tool of the present invention includes: a machine tool base, a machine tool workbench and a machine tool protective cover, wherein the machine tool workbench is arranged inside the machine tool protective cover, and the workpiece to be processed is placed on the machine tool workbench for processing. The machine tool protective cover is arranged on the machine tool base to prevent the cutting fluid from splashing out when the workpiece is processed, and the entire processing area is interrupted and isolated from the outside of the machine tool.

[0026] According to a first embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com