Device used for cleaning surface of petroleum pipeline

A surface cleaning device, oil pipeline technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high time cost, long construction period, high operating intensity of construction personnel, etc., to improve work efficiency, The effect of quick cleaning and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

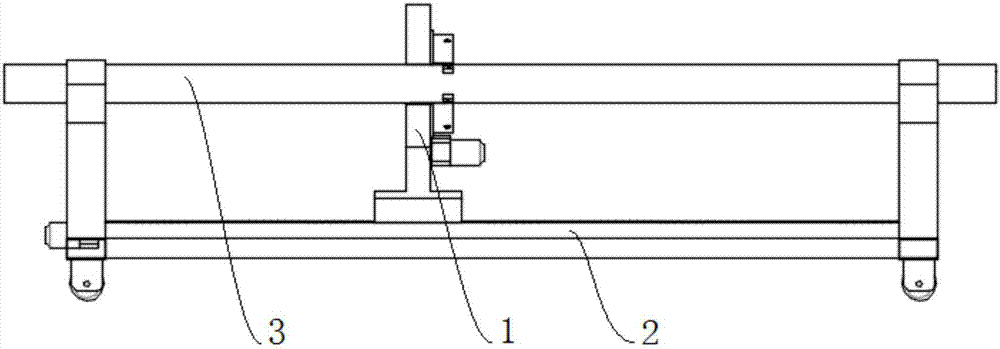

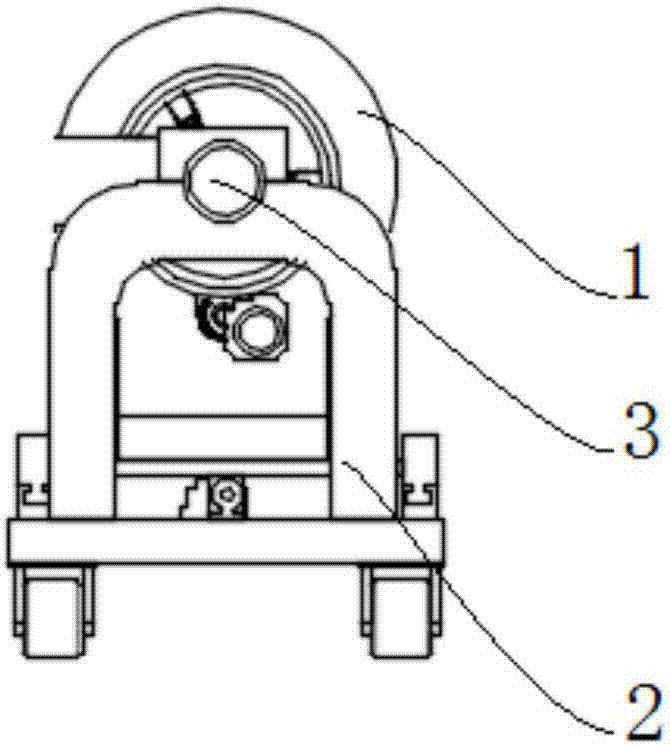

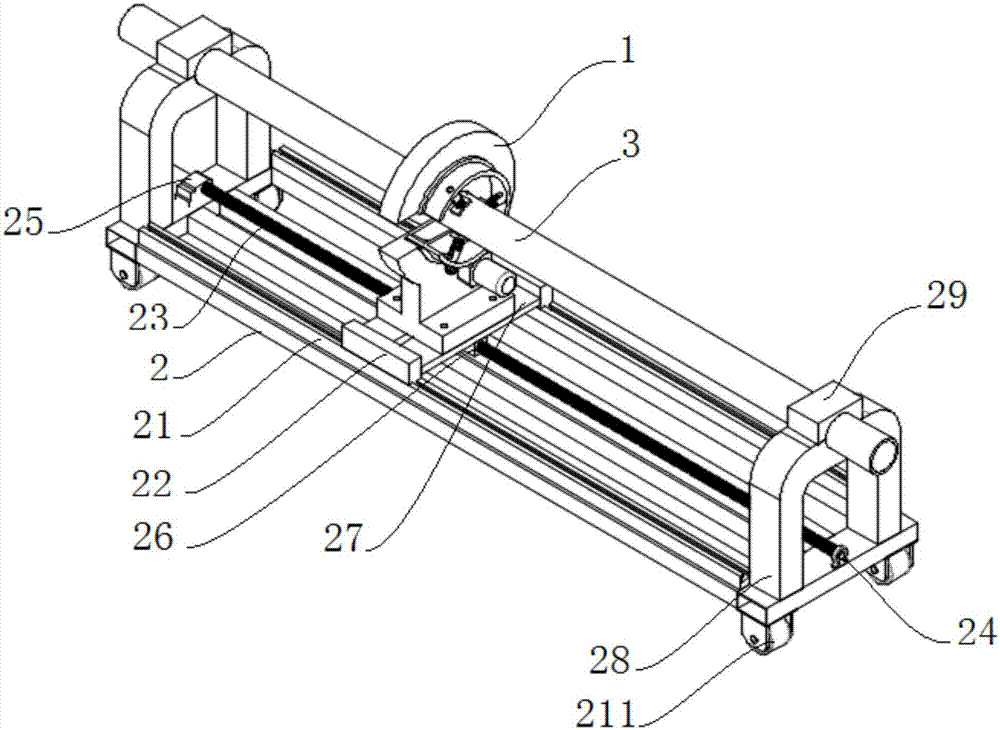

[0027] Such as Figure 1 to Figure 6 As shown, the present invention is used for oil pipeline surface cleaning device, comprises cleaning component 1, and described cleaning component comprises driving disc 11, motor 13, secondary gear 14, driven disc 12, grinding tool 128, and driving disc 11 is Disc-shaped, the drive disc 11 is provided with a first U-shaped notch 111, the first U-shaped notch 111 runs through both ends of the drive disc 11, the length of the first U-shaped notch 111 is greater than the radius of the drive disc 11, The first U-shaped notch 111 is left-right symmetrical along the centerline of the driving disk 11 . One of the end faces of the drive disc 11 is provided with an annular notch 112, the annular notch 112 is concentric with the drive disc 11, the drive disc 11 is provided with a mounting bracket 115, and the driven disc is installed in the annular notch 112 of the drive disc 11. 12. The limit ring 15 fixes the driven disc 12 in the annular notch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com