Insertion type vibrator for channel construction

A plug-in, vibrator technology, applied in the field of channel construction equipment, can solve the problems of poor mobility, dirty motor, inconvenient use, etc., and achieve the effects of avoiding inconvenience in cleaning, convenient in movement, and flexible in movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

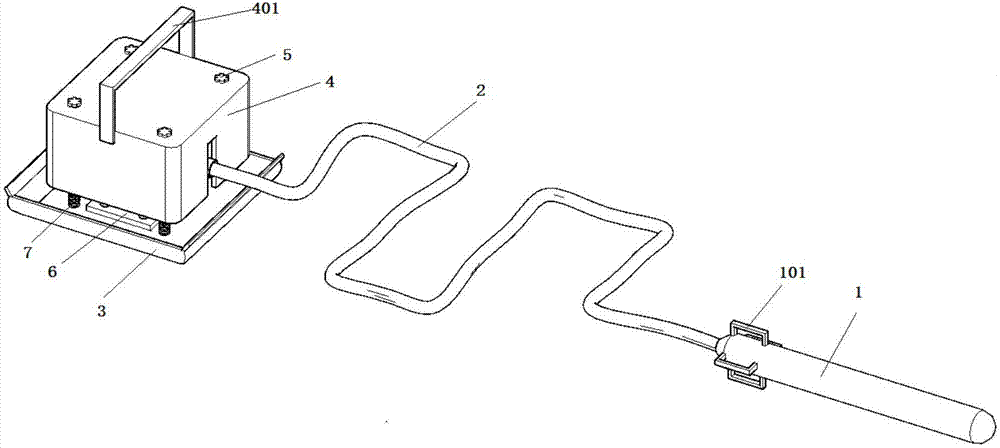

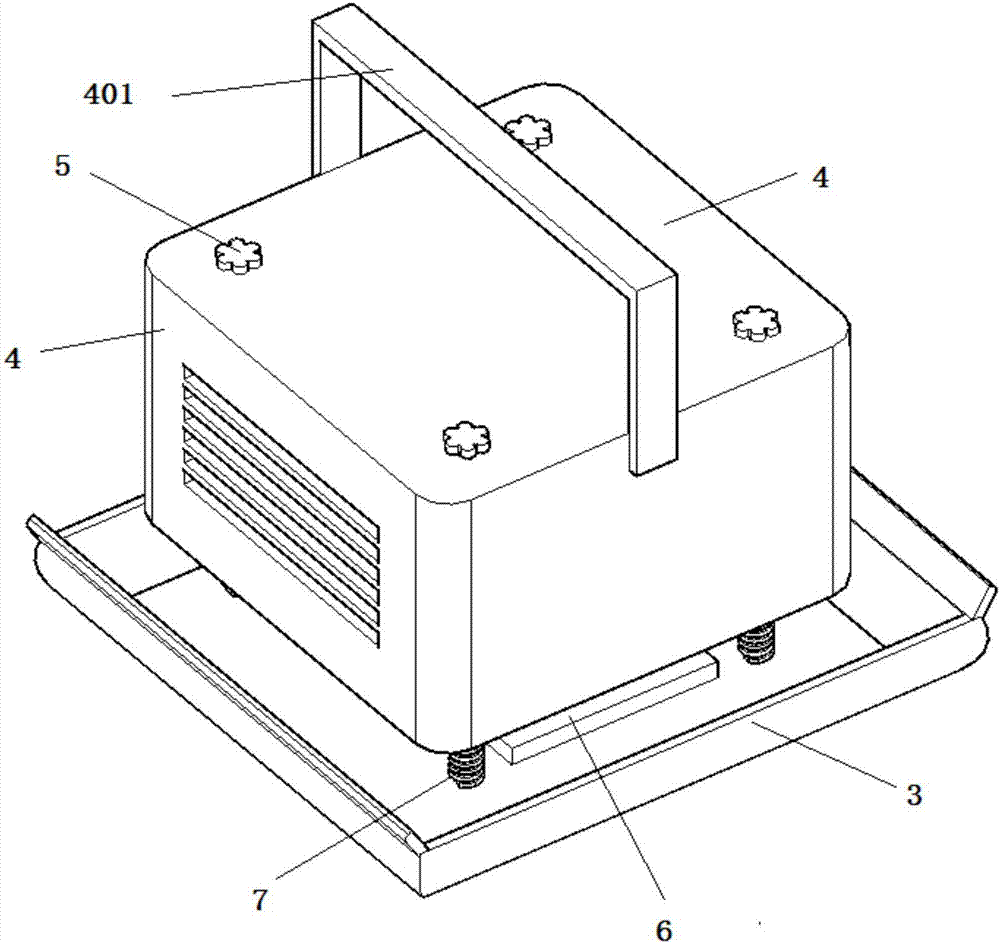

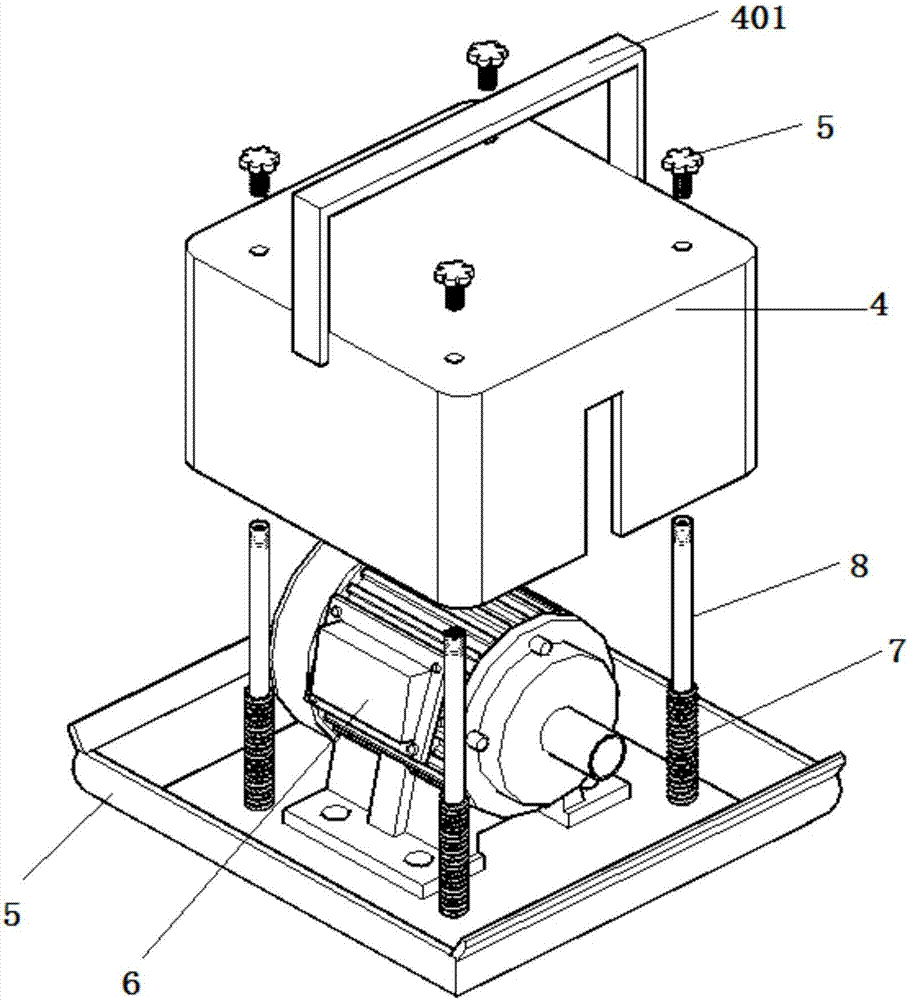

[0025] As attached figure 1 Attached Figure 5 Shown:

[0026] The present invention provides a plug-in vibrator for tunnel construction, which includes a vibrating rod 1, a handle 101, a driving hose 2, a fixed tray 3, a shield 4, a handle 401, a fixed shaft sleeve 402, and a locking bolt 5. , A motor 6, a spring 7 and a positioning shaft 8. A drive wire rope is arranged inside the drive hose 2, and one end of the drive wire rope is rotatably connected with the central drive shaft of the vibrator 1, and the other end is connected to the motor 6. The rotating shafts are rotatably connected together; the motor 6 is screwed to the top of the fixed tray 3, and four positioning shafts 8 are symmetrically and vertically supported around the motor 6; four positioning shafts 8 are provided with a thread on the top end Fixed holes; the front, rear, left, and right side walls of the fixed tray 3 are welded and fixed to an arc-shaped baffle, and the four arc-shaped baffles are welded to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com