Bagging machine

A bagging machine and sleeve technology, applied in the field of bagging machines, can solve the problems of manpower and material resources, time, waste, affecting the efficiency and quality of grapefruit bagging, and achieve the effect of reducing injuries and avoiding hard collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

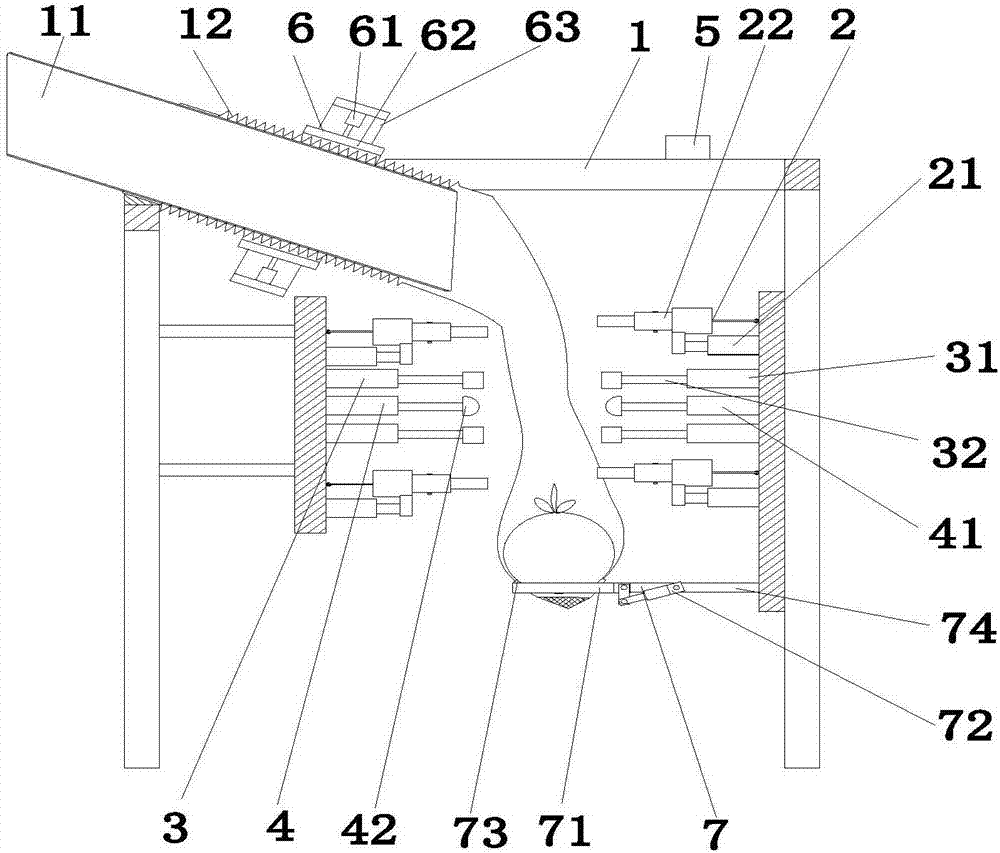

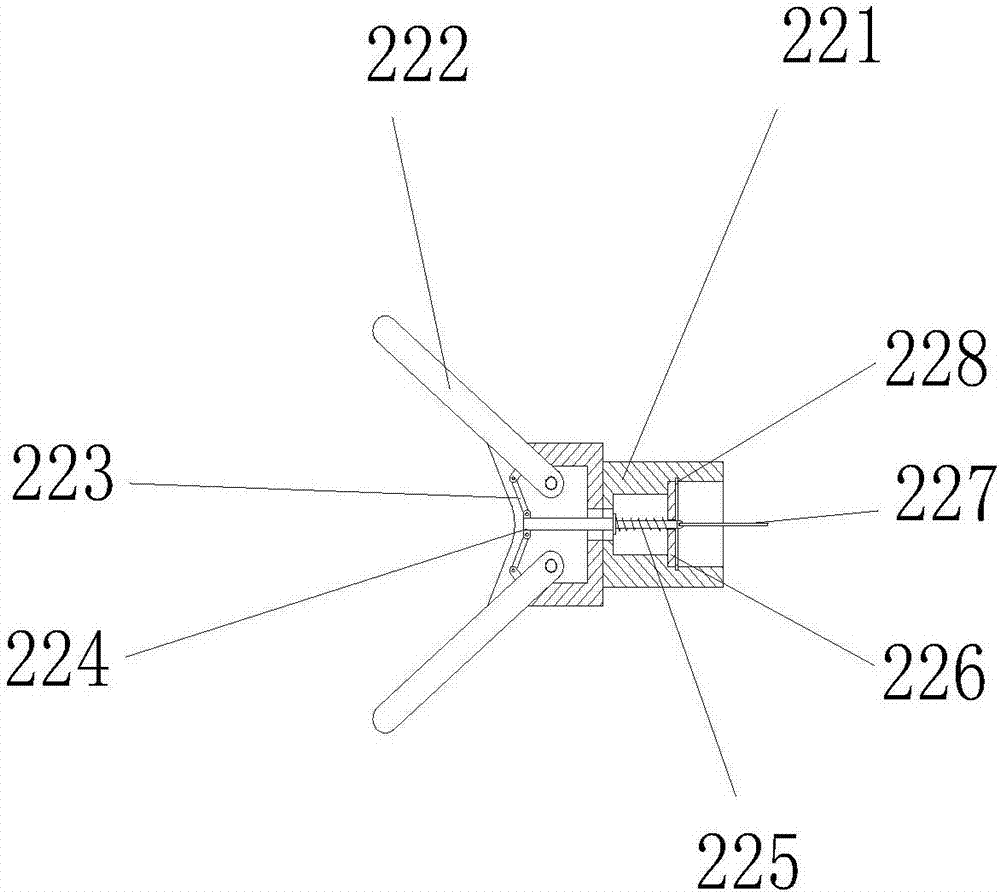

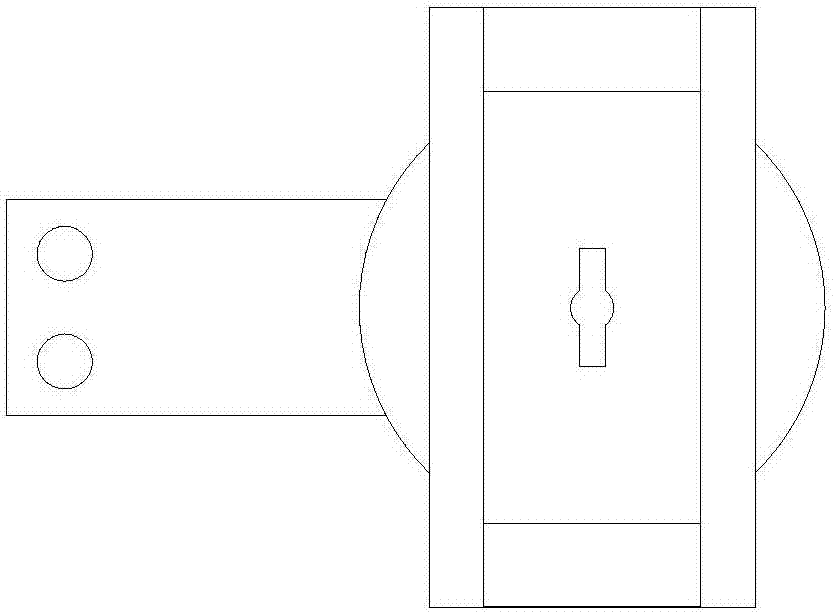

[0025] During specific implementation: Figure 1-2 As shown, a bagging machine includes a mounting bracket 1, a sleeve 11 is arranged above the mounting bracket 1, and a packaging bag 12 in the form of a cylindrical structure is sleeved on the outer side of the sleeve 11, the packaging bag Below 12 are provided two folding mechanisms 2, two sealing mechanisms 3 capable of sealing the packaging bags 12, and a cutting mechanism 4 for cutting the packaging bags 12, the mounting bracket The closing mechanism 2, the sealing mechanism 3, the cutting mechanism 4, the sealing mechanism 3, and the closing mechanism 2, the closing mechanism 2, the sealing mechanism 3, and the cutting mechanism are arranged in order from top to bottom. 4 are electrically connected to the controller 5. The folding mechanism 2 includes a pair of electric cylinders 21 arranged on both sides of the packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com