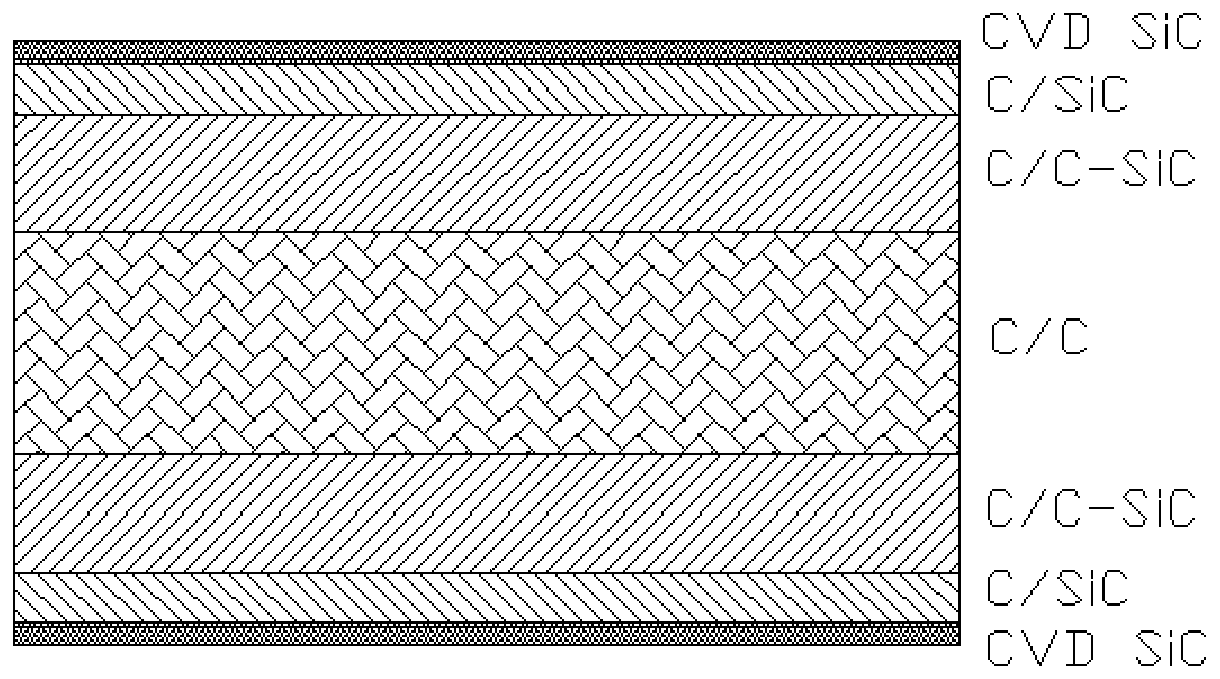

A kind of sandwich structure c/c-sic composite material and preparation method thereof

A composite material and sandwich technology, which is applied in the field of sandwich structure C/C-SiC composite material and its preparation, can solve the problems of long cycle, high preparation cost, and limited popularization and application, and achieve short cycle, lower material density, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

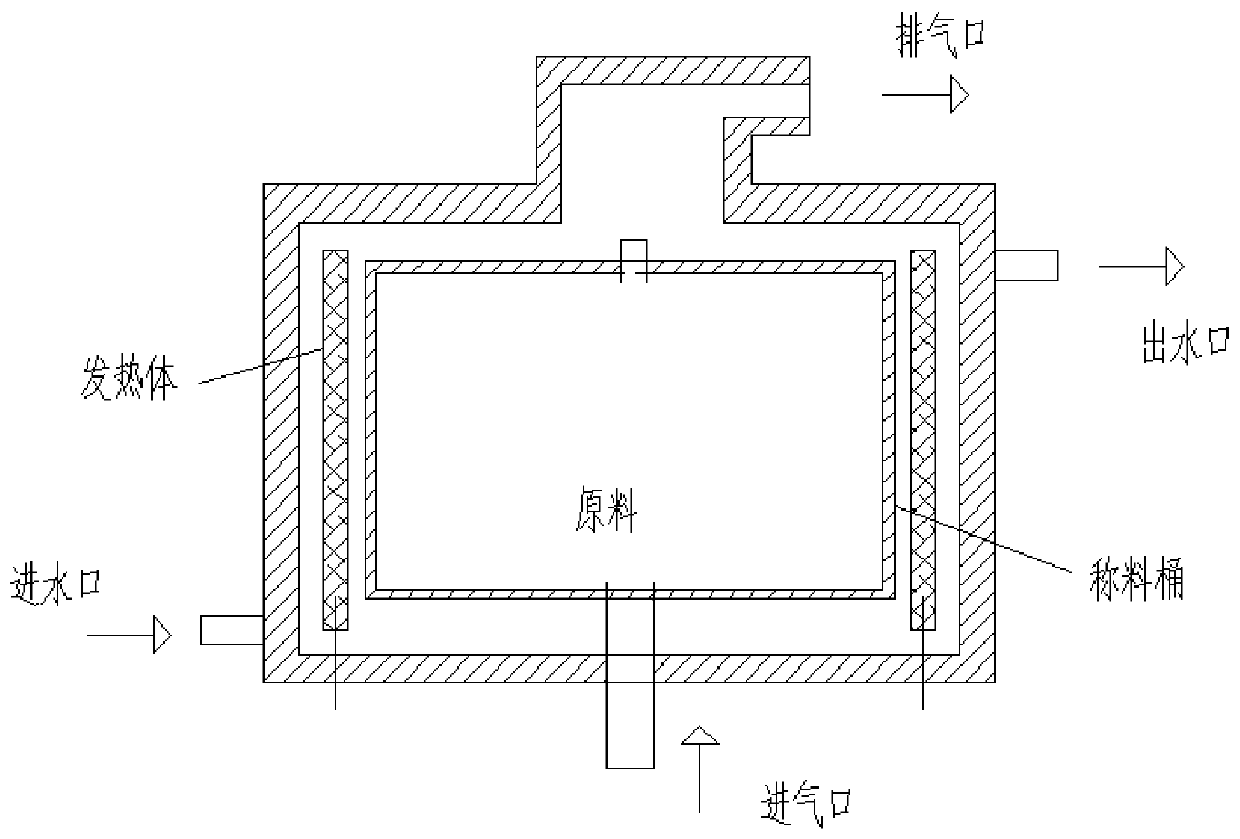

[0043] (2) Preparation of interface layer

[0044] Pyrolytic carbon is used as the carbon fiber interface layer. The introduction of pyrolytic carbon not only makes the material meet the debonding conditions, but also can regulate the residual thermal stress and reduce the frictional resistance caused by the roughness of the debonding surface, thus affecting the debonding. The size of the sliding resistance on the surface affects the contribution of fiber pulling out to the toughening effect.

[0045] The pyrolytic carbon interface layer was prepared by the ICVI process (such as figure 2 ). The raw material gas is Ar or N 2 For diluting gas, the flow rate is 0.05~0.5m 3 / h; liquefied natural gas (or methane, propane) is carbon source gas, the flow rate is 0.01~0.5m 3 / h; the deposition temperature is 700-1100° C., the deposition time is 3-10 h, and the thickness of the finally prepared pyrolytic carbon interface layer is 0.3-2 um.

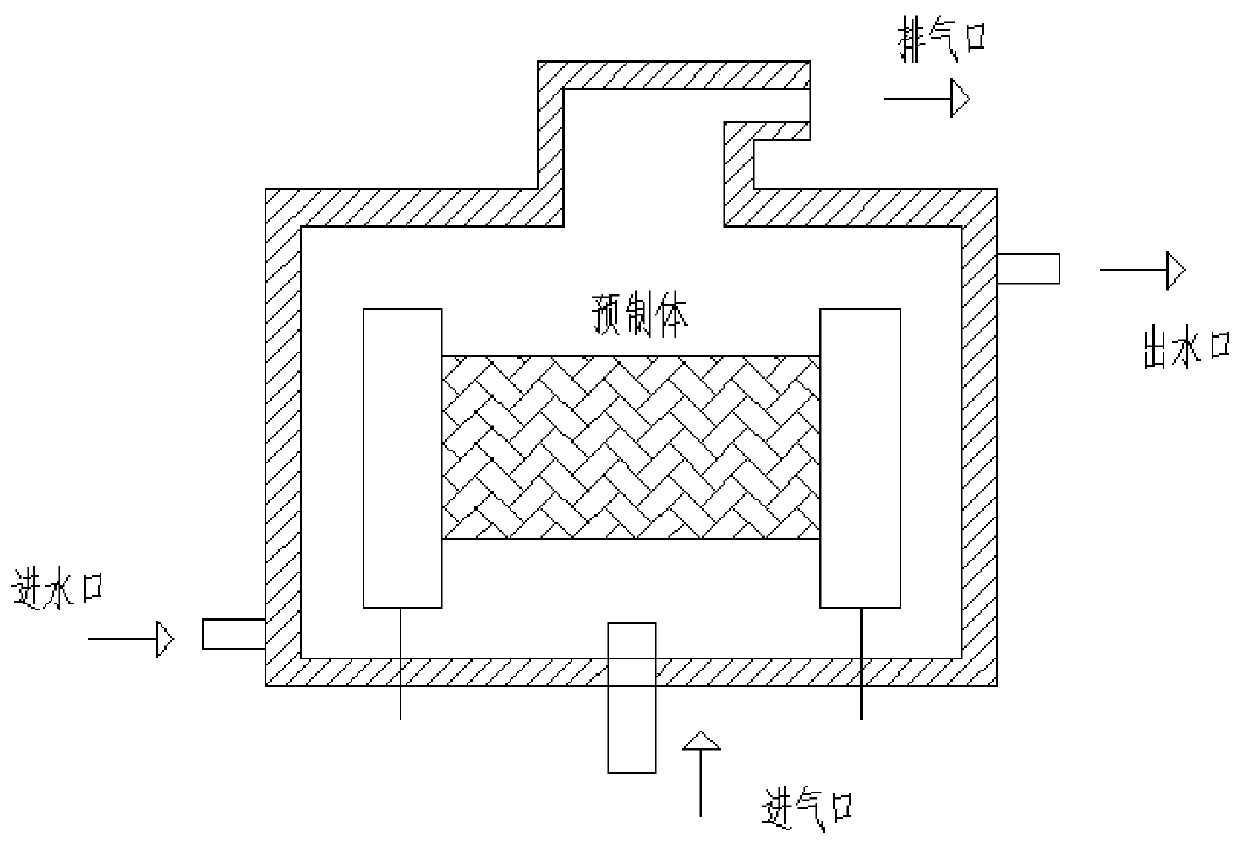

[0046] (3) Preparation of intermediate...

Embodiment 1

[0056] Taking 380×80×9mm as an example, the density is 0.5g / cm 3 2D needle felt; Pyrolytic carbon interface layer prepared by ICVI process, temperature 900°C, argon flow rate 0.2m 3 / h, propane 0.15m 3 / h, the deposition time is 5 hours; the C / C composite material with dense center and porous sides is prepared by E-CVI process, the temperature is 700-1000°C, the flow ratio of argon:propane is 2:1, and the deposition time is 5 hours; E-CVI process to deposit SiC substrate, pass hydrogen, argon and trichloromethylsilane into the E-CVI furnace, the volume ratio is 5:5:1, the temperature is 700-1000°C, and the deposition is 15 hours to obtain the required sandwich structure Composite material; after CNC machining and forming, ultrasonic cleaning; CVD coating, temperature 1200 ° C, hydrogen, argon and trichloromethylsilane, volume ratio 5:5:1, time 30 hours, the final density of the material is 1.95g / cm 3 , The total material preparation cycle is 55 hours. Figure 5 Backscatt...

Embodiment 2

[0058] Take 380×80×30mm as an example, the density is 0.5g / cm 3 2D needle felt; Pyrolytic carbon interface layer prepared by ICVI process, temperature 900°C, argon flow rate 0.2m 3 / h, propane 0.15m 3 / h, the deposition time is 5 hours; the C / C gradient material is prepared by E-CVI process, the temperature is 700-1000 °C, the flow ratio of argon:propane is 2:1, and the deposition time is 15 hours; the SiC substrate is deposited by E-CVI process , put hydrogen, argon and trichloromethylsilane into the E-CVI furnace, the volume ratio is 5:5:1, the temperature is 700-1000°C, and the composite material with the required sandwich structure is obtained after deposition for 25 hours; CNC machining is adopted After forming, ultrasonic cleaning; CVD coating, temperature 1200 ℃, hydrogen, argon and trichloromethylsilane, volume ratio 5:5:1, cycle 30 hours, final density of material 1.90g / cm 3 , The total material preparation cycle is less than 75 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com