Large-flow floor drain with observation window

An observation window and large flow technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of small internal space, small flow, inconvenient maintenance, etc., to reduce the frequency of cleaning and the effect of large total flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

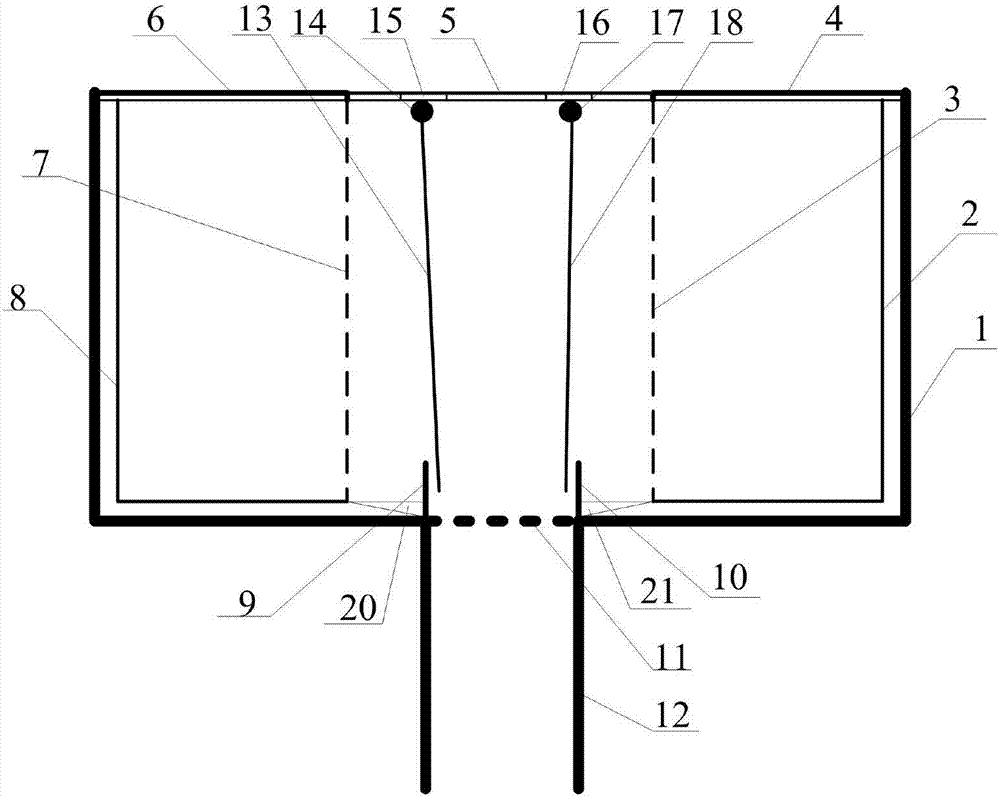

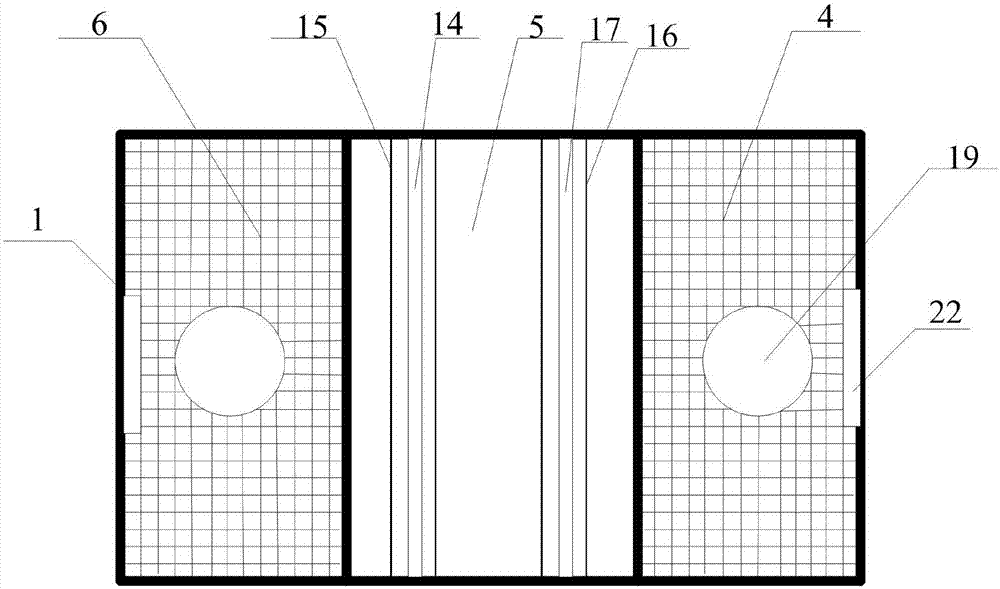

[0049] Such as figure 1 with figure 2As shown, a large-flow floor drain with an observation window of the present invention mainly includes: a casing 1, a second dirt bin 2, a second stainless steel mesh 3, a second upper cover 5, a first upper cover 6, and a first stainless steel mesh. Net 7, first dirt chamber 8, first dirt baffle plate 9, third stainless steel mesh 11, drainage pipe connecting hole 12, first water retaining sheet 13, first rotating shaft 14, first observation window 15, washing machine drain 19 , the first sedimentation tank 20, and the pulling port 22.

[0050] Grooves are arranged on the periphery of the upper edge of the casing 1 to facilitate fixing the upper cover.

[0051] The first loam cake 6 and the second loam cake 5 are all fixed on the top of the shell 1, the second loam cake 5 is a closed lid body, the first loam cake 6 has a water leakage hole, the first loam cake 6 and the second loam cake 5 adjacent to each other, the first upper cover 6...

specific Embodiment approach 2

[0061] Such as figure 1 with figure 2 As shown, a large-flow floor drain with an observation window of the present invention mainly includes: a casing 1, a second dirt bin 2, a second stainless steel mesh 3, a third upper cover 4, a second upper cover 5, a first upper cover Cover 6, first stainless steel mesh 7, first dirt bin 8, first dirt baffle 9, second dirt baffle 10, third stainless steel mesh 11, drainage pipe connection hole 12, first water baffle 13, first The rotating shaft 14, the first observation window 15, the second observation window 16, the second rotating shaft 17, the second water retaining sheet 18, the washing machine drain 19, the first sedimentation tank 20, the second sedimentation tank 21, and the lifting port 22.

[0062] Grooves are arranged on the periphery of the upper edge of the casing 1 to facilitate fixing the upper cover.

[0063] The first loam cake 6, the second loam cake 5 and the third loam cake 4 are all fixed on the top of the shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com