Explosion-proof test system

A test system and special technology, applied in the direction of material explosion, can solve problems such as difficult operation, complex structure, and heavy movement process, and achieve the effect of convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

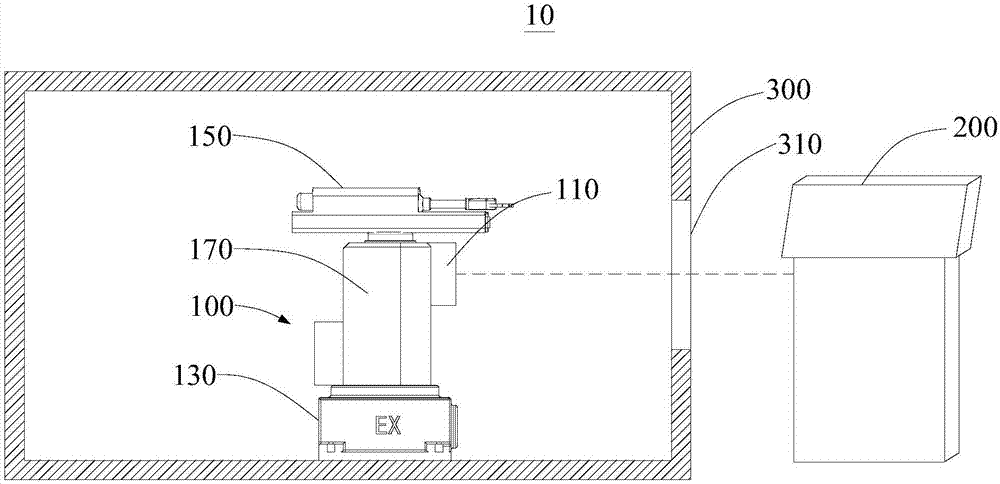

[0034] see in conjunction Figure 1 to Figure 2 , an explosion-proof test system 10, comprising a remote console 200, an explosion-proof chamber 300 and a special explosion-proof manipulator 100, the remote console 200 is arranged outside the explosion-proof chamber 300, the special explosion-proof manipulator 100 is accommodated in the explosion-proof chamber 300, and the explosion-proof chamber 300 A viewing window 310 is provided on the side wall.

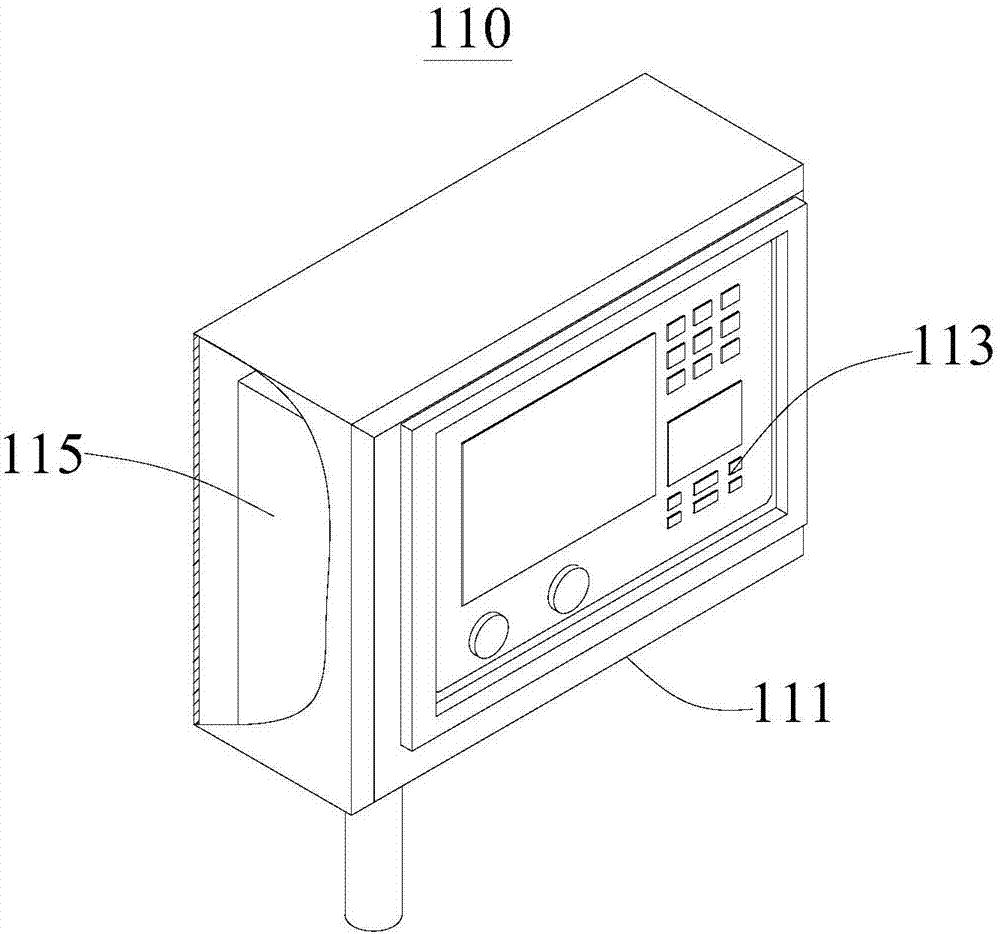

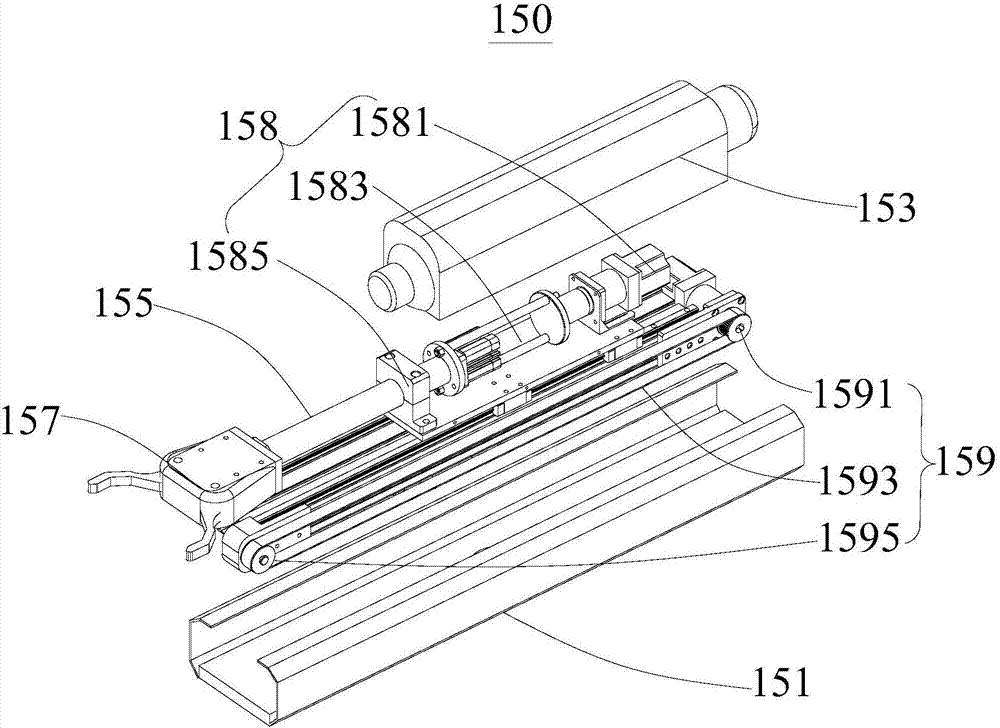

[0035] The special explosion-proof manipulator 100 includes an explosion-proof hand control box 110, an explosion-proof electrical base 130, a telescopic arm 150, a lifting rotating shaft 170 and a protective shell 190. The telescopic arm 150 is rotatably connected to the top of the lifting rotating shaft 170. Into the protective shell 190, the protective shell 190 is fixedly connected to the top of the explosion-proof electrical base 130, the explosion-proof manual control box 110 is fixedly connected to the protective shell 19...

no. 2 example

[0054] This embodiment provides an explosion-proof test system 10, whose basic structure, principle and technical effect are the same as those of the first embodiment. content. Compared with the first embodiment, the difference of this embodiment is that a power supply unit (not shown in the figure) is added.

[0055] The explosion-proof test system 10 includes a remote console 200, an explosion-proof room 300, a special explosion-proof manipulator 100, and a power supply unit. The remote console 200 and the power supply unit are all arranged outside the explosion-proof room 300. A viewing window 310 is provided on the side wall of the chamber 300 , and the power supply unit is electrically connected to the special explosion-proof manipulator 100 and the remote console 200 to supply power to the special explosion-proof manipulator 100 and the remote console 200 .

[0056] The special explosion-proof manipulator 100 includes an explosion-proof hand control box 110, an explosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com