Parallel industrial robot training table

A technology of industrial robots and training platforms, applied to instruments, educational tools, teaching models, etc., can solve the problems of unrealistic and lack of practical teaching of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

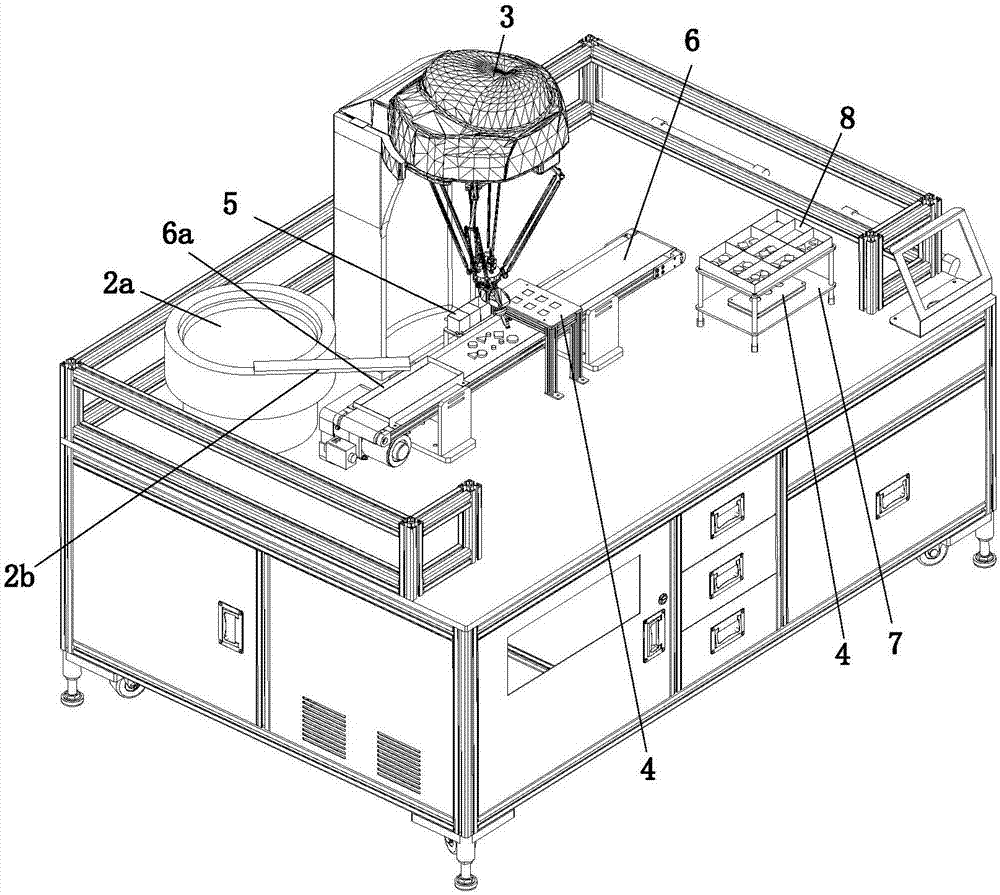

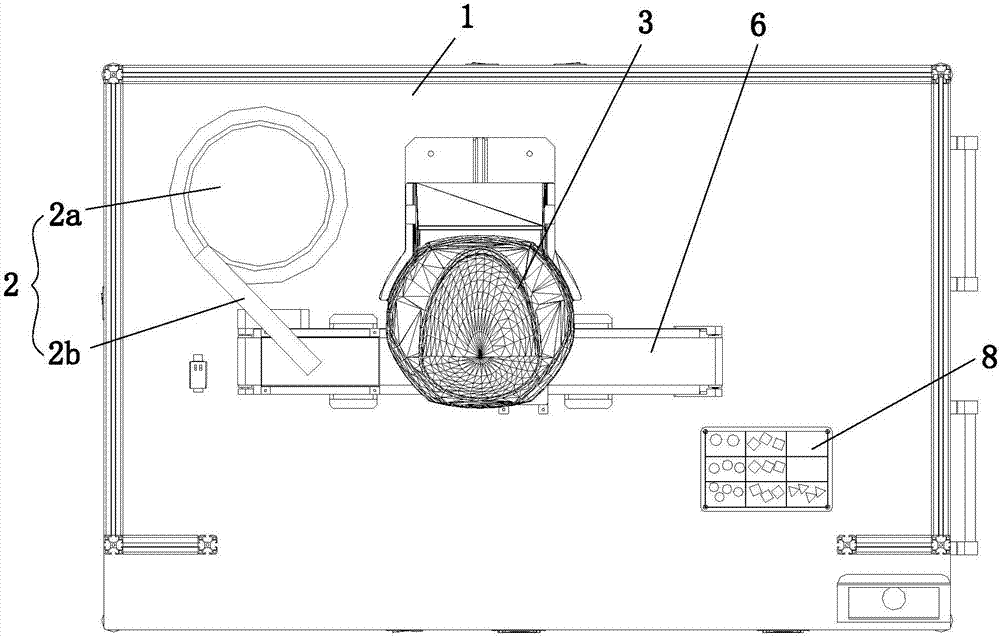

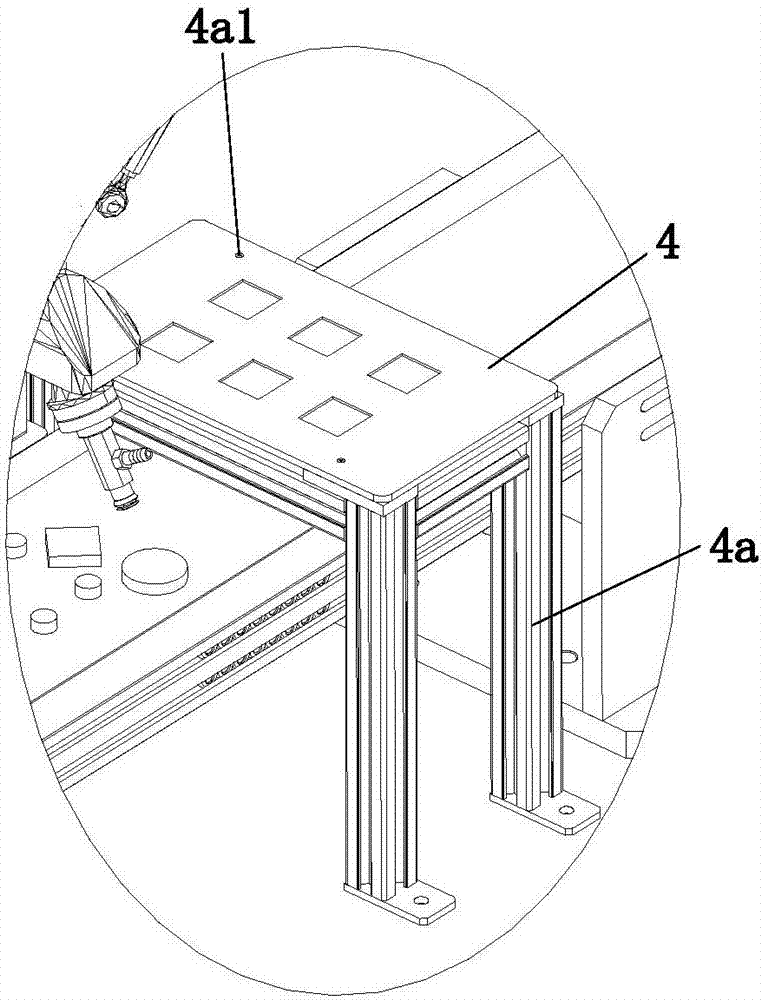

[0021] refer to Figure 1 to Figure 3 A kind of parallel industrial robot training platform shown, comprises training workbench 1, feeding mechanism 2, conveying assembly line mechanism and parallel robot body 3, and described parallel robot body 3 is fixed on the training workbench 1, and feeding The mechanism 2 is connected to the feeding end of the conveying assembly line mechanism, and the conveying assembly line mechanism passes under the parallel robot body 3, and the parallel robot body 3 is equipped with a two-dimensional vision system for distinguishing the color and size of the workpiece passing under it, The conveying line mechanism is provided with a replaceable material tray 4, and the material tray 4 is provided with a plurality of grooves of the same shape, and the outside of the conveying line mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com