Cyclone separation type sintered-plate composite deduster

A technology of cyclone separation and sintered plate, which is applied in the direction of separation method, dispersed particle separation, combined device, etc., can solve the problem that the sintered plate dust collector cannot be used normally, and achieve easy cleaning, good separation effect, and excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

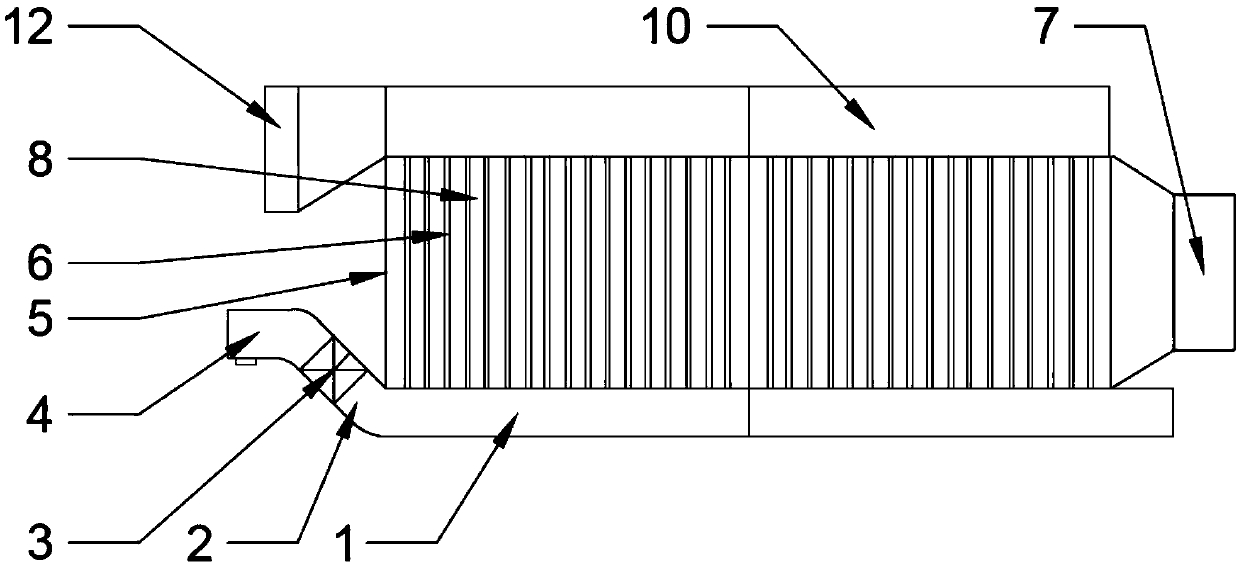

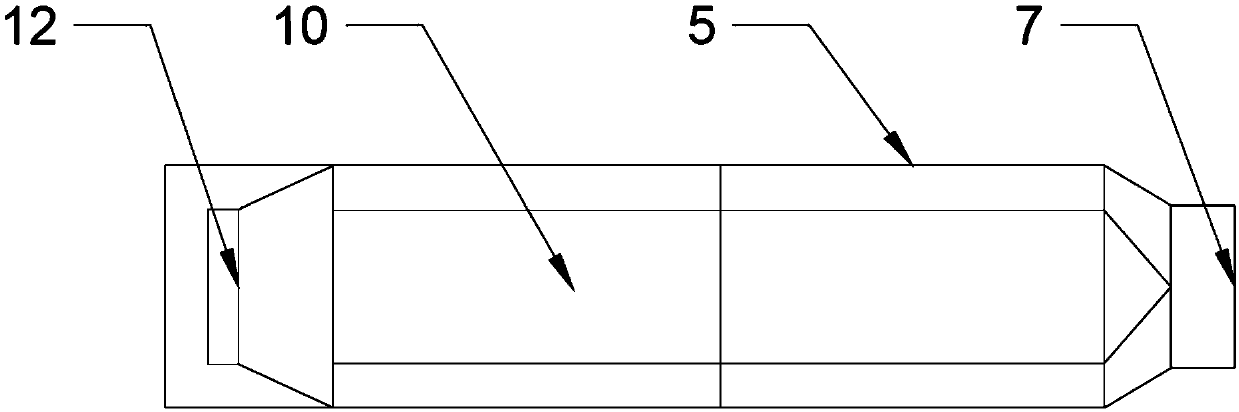

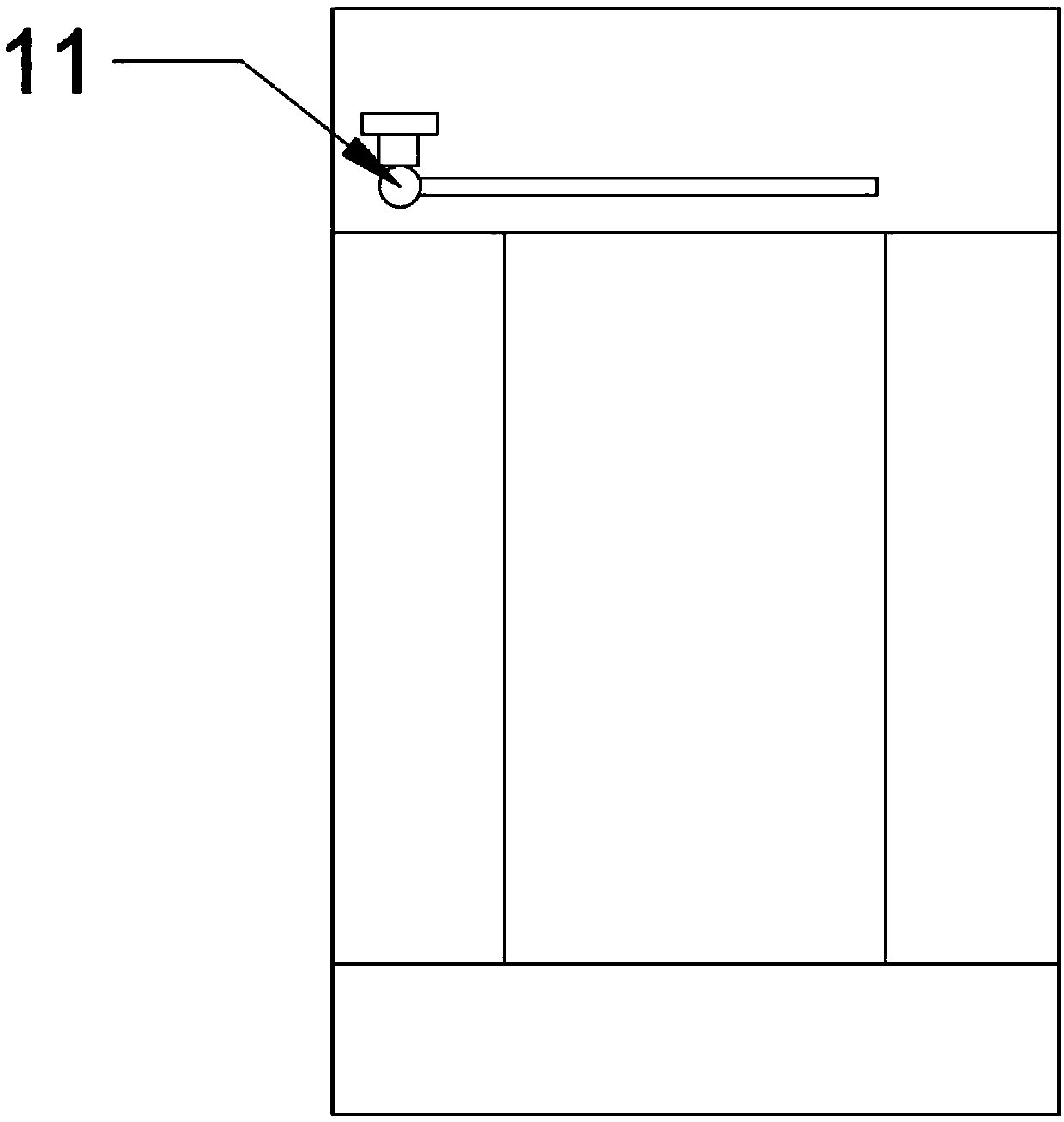

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] When the present invention is implemented in practice, a cyclone separation type sintered plate composite dust collector includes a scraper machine 1, and a scraper machine exhaust pipe 2 is connected to the scraper machine 1, and the scraper machine The exhaust pipe 2 is provided with a backstop seal 3, the scraper machine exhaust pipe 2 is connected with a scraper machine ash discharge port 4, and the scraper machine 1 is connected with a middle box body 5, The middle box 5 is provided with a sintered plate 6, and one side of the middle box 5 is connected with an air inlet 7, and the air inlet 7 is connected with the air inlet channels 8 on both sides of the middle box 5 , the air inlet 7 is provided with a swirl device 9, the middle box 5 is connected with an upper box 10, the middle box 5 and the upper box 10 are connected structures, and the One ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap