An SNCR denitration process and SNCR denitration equipment suitable for rotary kiln-grate pellet flue gas

A technology of grate pelletizing and rotary kiln, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of easy hardening of urea stacks, difficult control, and high safety requirements, and achieve low investment and operation costs. , the best SNCR denitrification efficiency, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

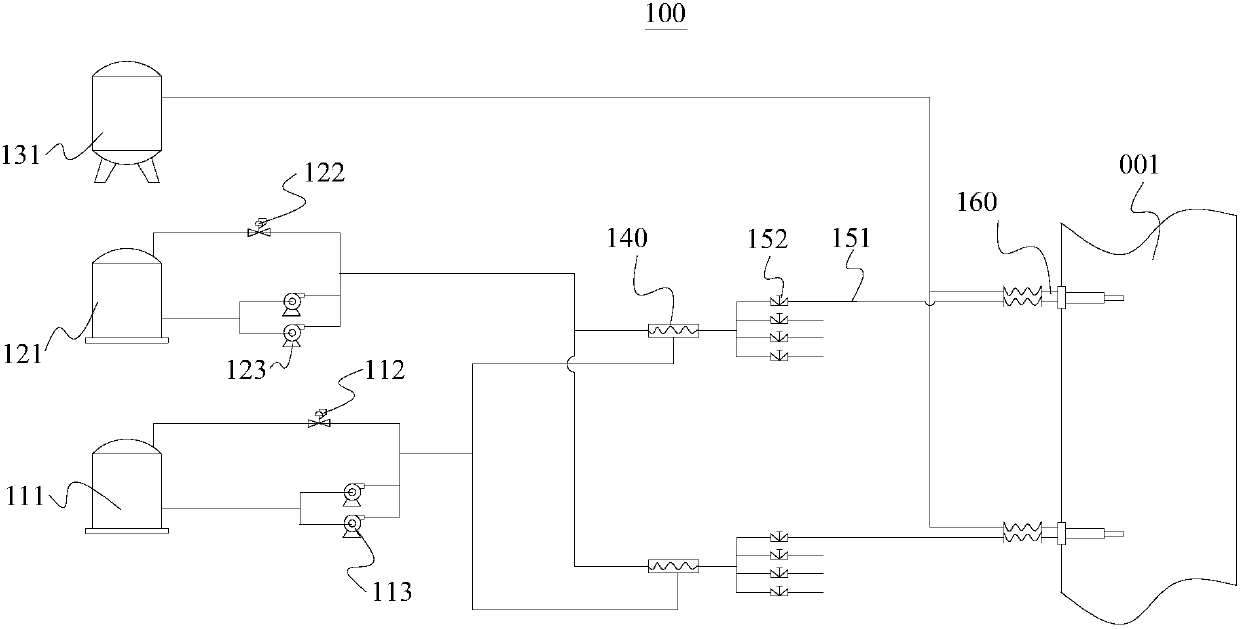

[0030] The embodiment of the present invention provides a SNCR denitrification process suitable for rotary kiln-grate pellet flue gas, which is to dilute the ammonia water produced by the steel plant on-line to a mass concentration of 5% to 10%, and use compressed air to dilute the diluted The final ammonia water is atomized and sprayed into different areas of the rotary kiln reaction zone (temperature is 850-1100°C), the ammonia gas produced by the ammonia water and the NO x Carry out selective non-catalytic reduction reaction to pellet NO in flue gas x converted to non-polluting N 2 and H 2 O. The SNCR denitrification process of the embodiment of the present invention applies the SNCR method to the sintering and pelletizing denitrification of steel mills, and proposes a new idea for sintering and pelletizing denitrification of steel mills. Steel mills generally have coking plants, and the coking process will produce ammonia water. For the denitrification needs of steel mi...

no. 2 example

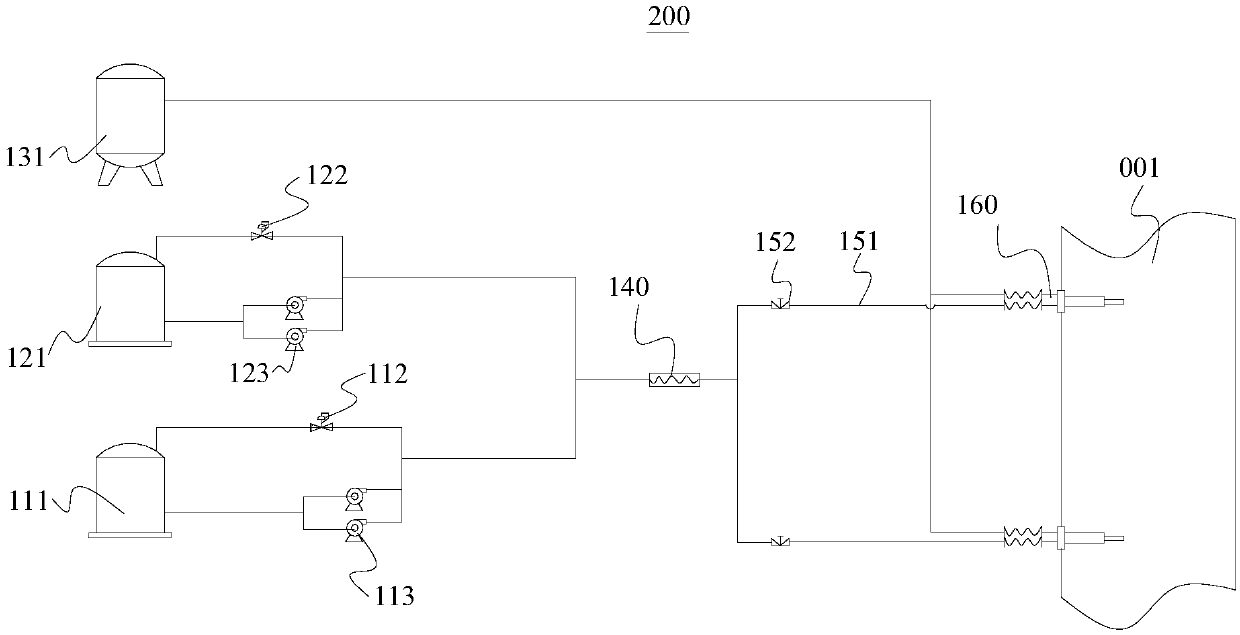

[0041] Please refer to figure 2 , this embodiment provides an SNCR denitrification device 200 suitable for rotary kiln-grate pellet flue gas, which includes an ammonia water tank 111, a dilution water tank 121, a compressed air storage tank 131, a mixing and dilution device 140, a metering distribution device and A plurality of spraying devices 160 arranged in different areas of the reaction zone of the rotary kiln 001, the mixing and diluting device 140 communicates with the ammonia water tank 111 and the dilution water tank 121 respectively, the mixing and diluting device 140, the metering and distributing device, and the spraying device 160 communicate in sequence, and the compression The air storage tank 131 communicates with the injection device 160 . The ammonia water in the ammonia water tank 111 and the dilution water in the dilution water tank 121 are respectively sent to the mixing and diluting device 140 to be mixed and diluted, and then metered and distributed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com