Upper disc device of double-side grinding machine

A double-sided grinding and driving device technology, which is applied in the direction of grinding devices, grinding machine tools, grinding driving devices, etc., can solve the problems of complex manufacturing and maintenance, low processing precision, and large vibration, so as to reduce the difficulty of manufacturing and processing and improve the accuracy of equipment , Solve the effect of poor fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

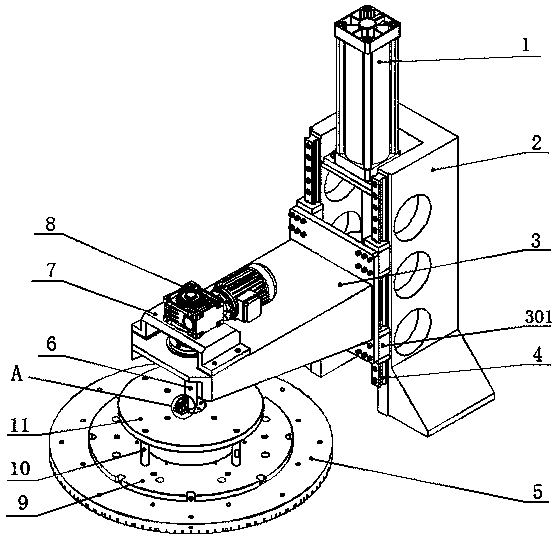

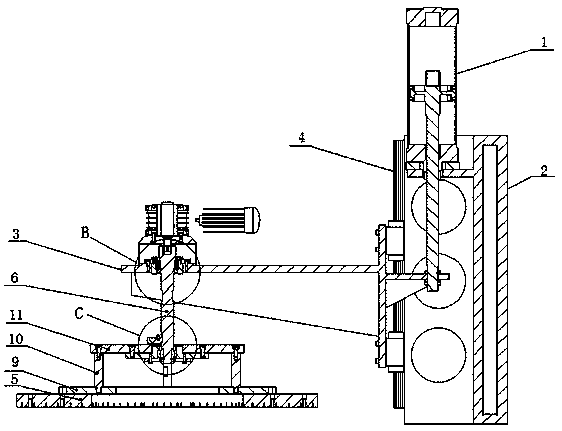

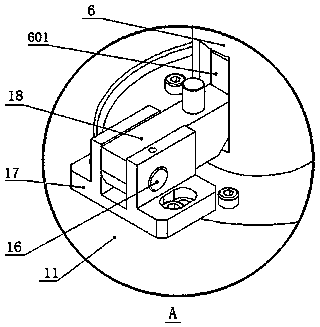

[0018] See figure 1 —— Figure 5 , the upper plate device of the double-sided grinding machine provided by the present invention comprises a frame 2, a moving support 3, a main shaft 6 and an upper plate assembly, the top of the frame 2 is provided with a first driving device cylinder 1, and one side of the frame 2 There are two parallel linear slide rails 4 vertically, the moving bracket 3 is installed on the linear sliding rail 4 through the slider 301, the cylinder 1 is connected with the moving bracket 3; the moving bracket 3 is a cantilever beam, and the end of 7. The second driving device deceleration motor 8 is installed. The output shaft of the deceleration motor 8 is connected to the main shaft 6. A pair of rolling bearings 14 are installed on the main shaft 6 through a rolling bearing nut 12. The outer ring of the rolling bearing 14 is mounted on the bearing fixed on the moving bracket 3. The lower end of the main shaft 6 is equipped with a joint bearing 20, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com