Shuttle propeller and circular weaving machine

A propeller and shuttle technology, applied in circular looms, looms, textiles, etc., can solve the problems of severe friction wheel wear, slipping, and abnormal rolling noise, so as to improve service life, improve transmission efficiency, reduce wear and tear The effect of movement noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-5 The application is described in further detail.

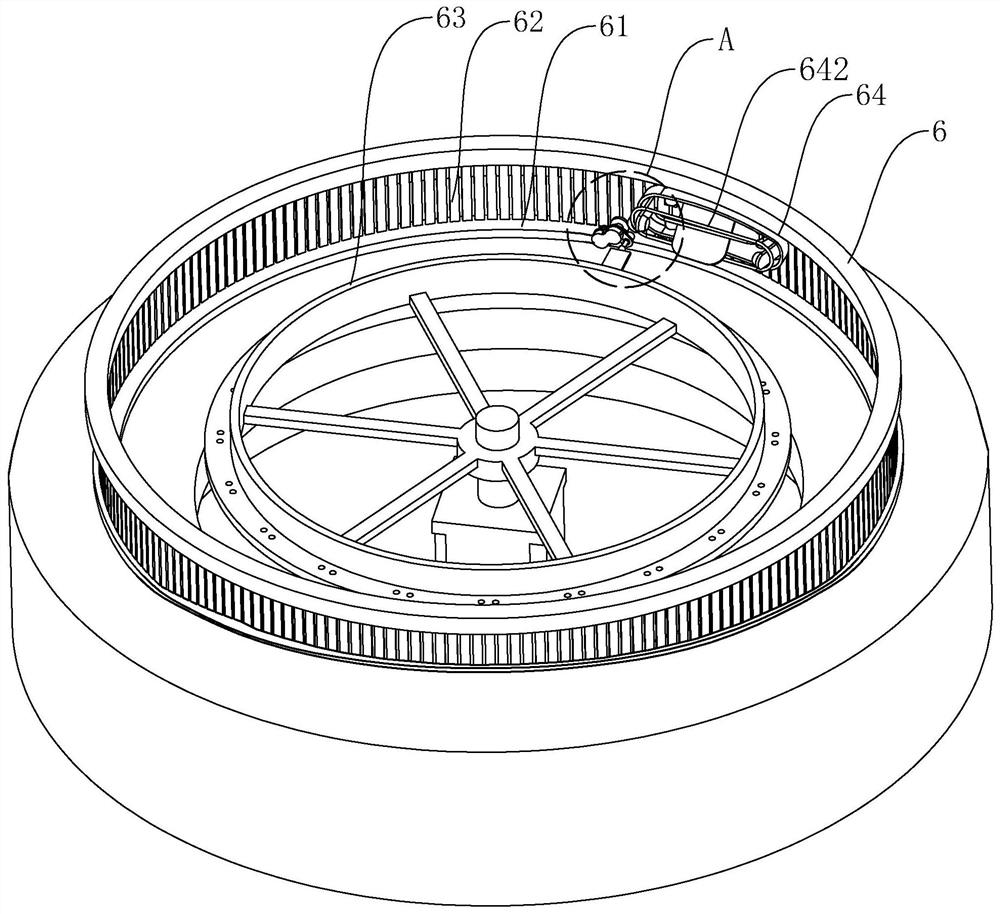

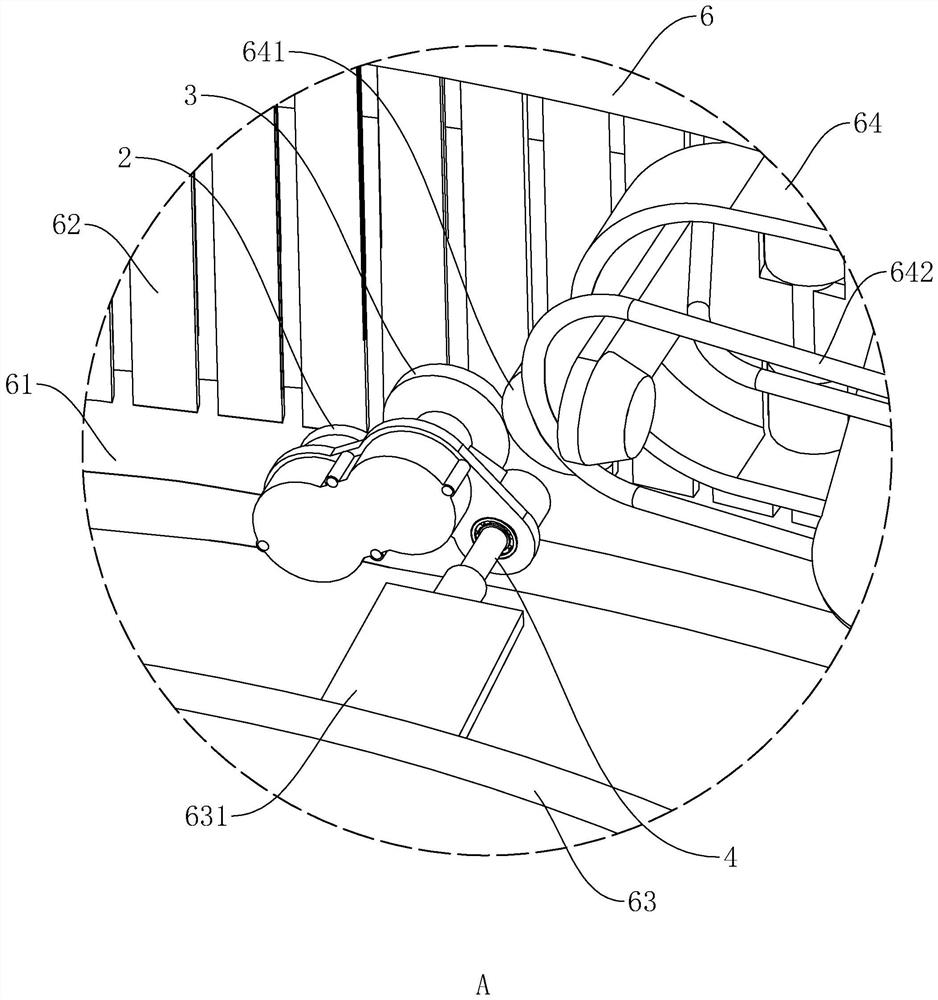

[0039] The embodiment of the present application discloses a shuttle propeller and a circular loom, such as figure 1 As shown, the circular loom includes a frame 6, the frame 6 is provided with a concentric propulsion disc 63, a friction track 61 and a circular shed 62, the circular shed 62 is provided with a shuttle 64, and the shuttle propeller is installed on the propulsion disc 63 On, and be used for pushing shuttle 64 and be positioned at running in circular shed 62.

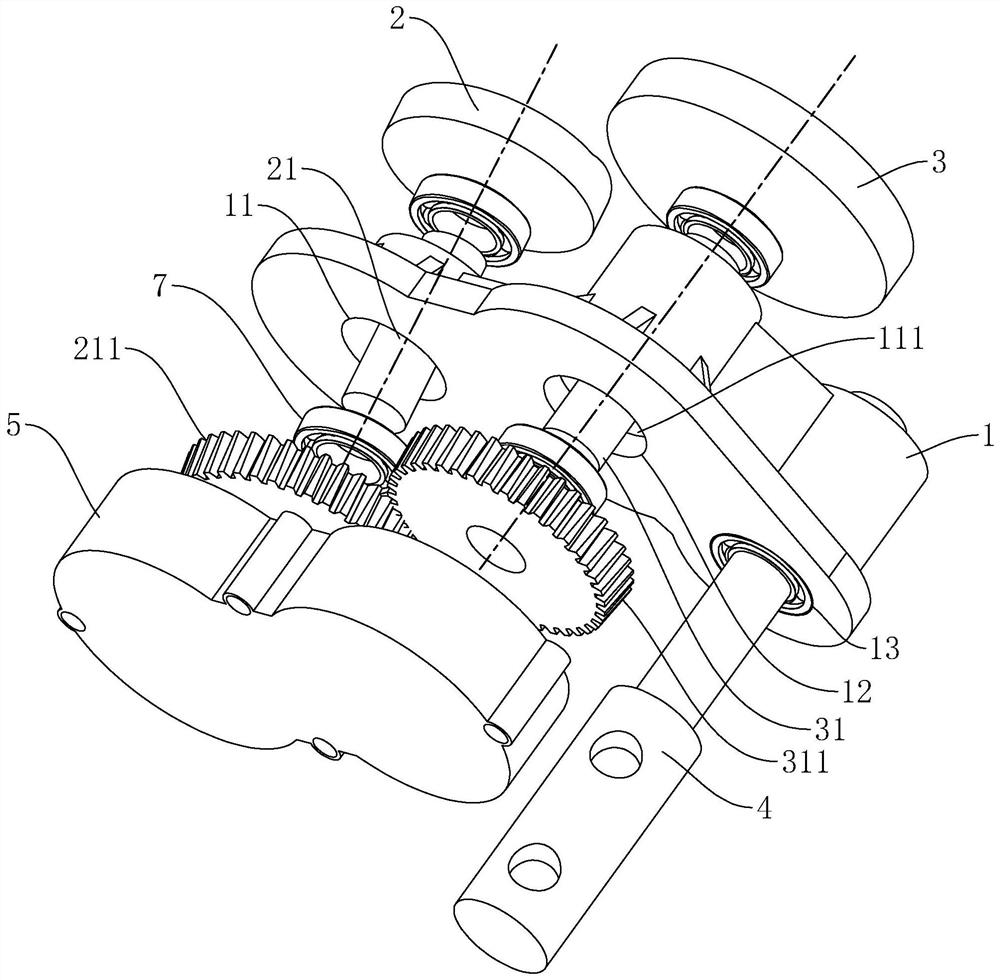

[0040] like figure 2 and 3 As shown, the shuttle propeller includes a propulsion frame 1, a friction wheel 2 and a propulsion wheel 3. A first installation hole 11, a second installation hole 12 and a third installation hole 13 are sequentially opened on the propulsion frame 1 along its thickness direction. The sequence is the same as the revolution direction of the propulsion disc 63 . A friction wheel sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com