Device for achieving three-dimensional laser volume measurement by worm wheel and worm transmission mode

A three-dimensional laser and volume measurement technology, which is applied in the direction of gear transmission, measurement device, transmission device, etc., can solve the problems of inability to achieve high-torque, stable and high-precision transmission, irregular distortion of point cloud, and inaccurate data, etc., to reduce Measuring the effect of cost, wide application range and large application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

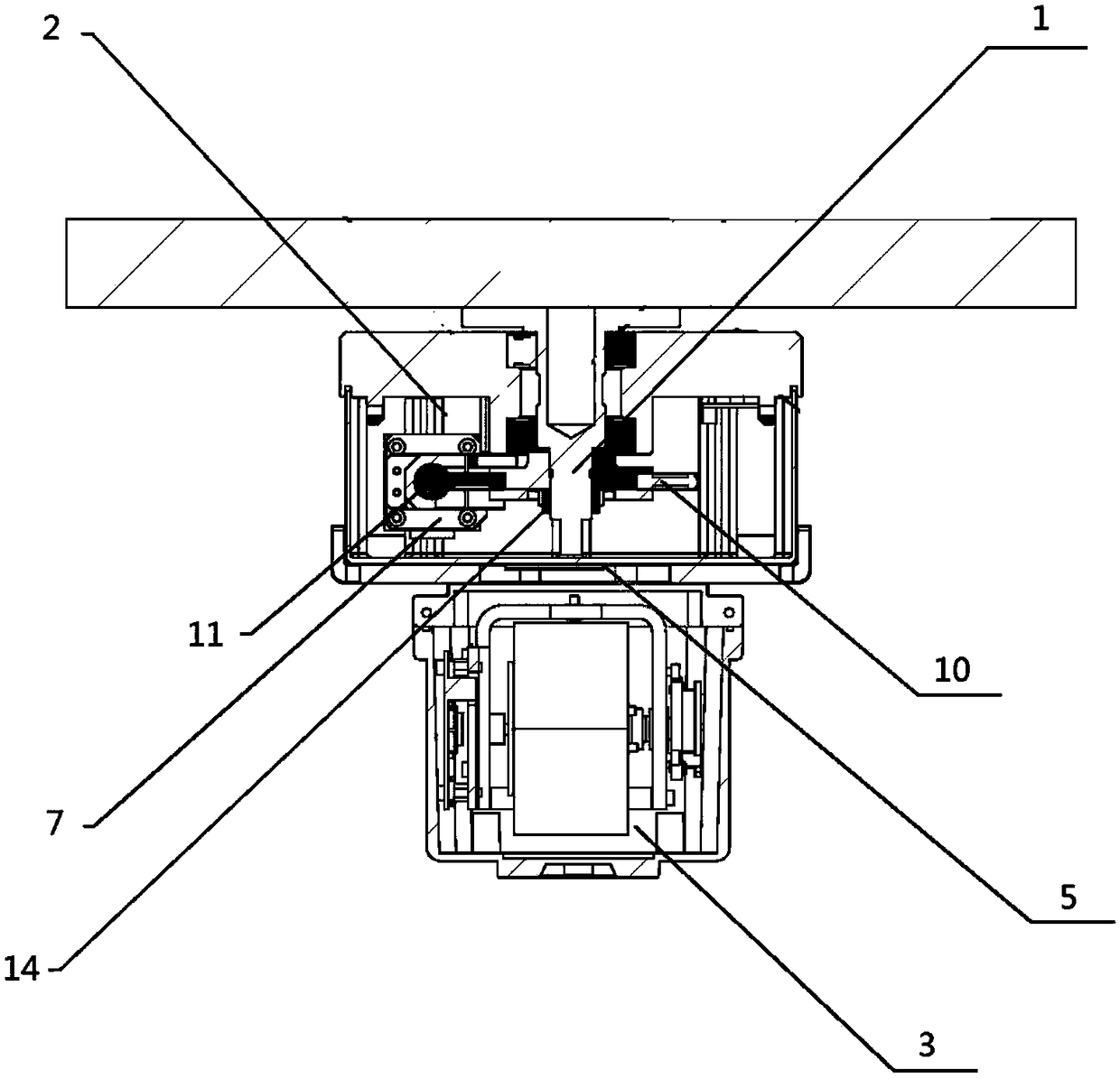

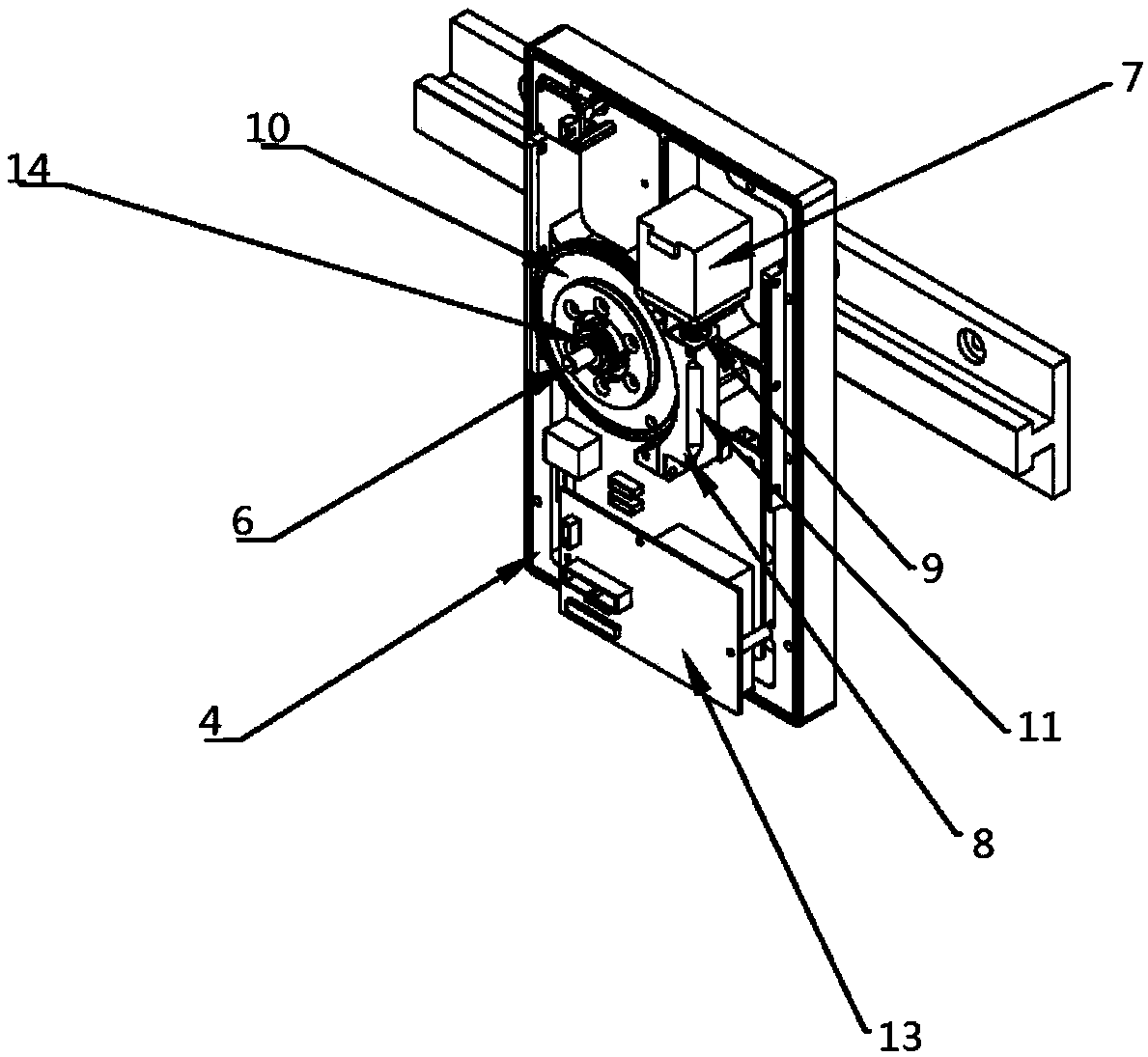

Embodiment 1

[0033] A three-dimensional laser volume measurement device using worm gear transmission, the number of worm gears is 4, and the number of worm gears is 200;

[0034] Transmission ratio i=speed of worm (n1) / speed of worm wheel (n2)=number of teeth of worm wheel (n2) / number of heads of worm (n1);

[0035] Transmission ratio i=200 / 4=50;

[0036] 50=n1 / n2;

[0037] 50n2=n1;

[0038] The speed of the stepper motor is controlled by the instructions of the main board to drive the worm 50 revolutions per minute through the coupling, so that the worm gear can drive the shaft and the base to 1 revolution per minute, and finally realize the low-speed transmission of the laser measurement module. The measured point cloud image is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com