Low-frequency cable component press joining system labeling device

A cable assembly and low-frequency technology, which is applied in the field of labeling devices for low-frequency cable assembly crimping systems, can solve problems such as easy falling and label sticking is not firm, and achieve low manufacturing costs, avoid easy falling, and avoid excessive pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

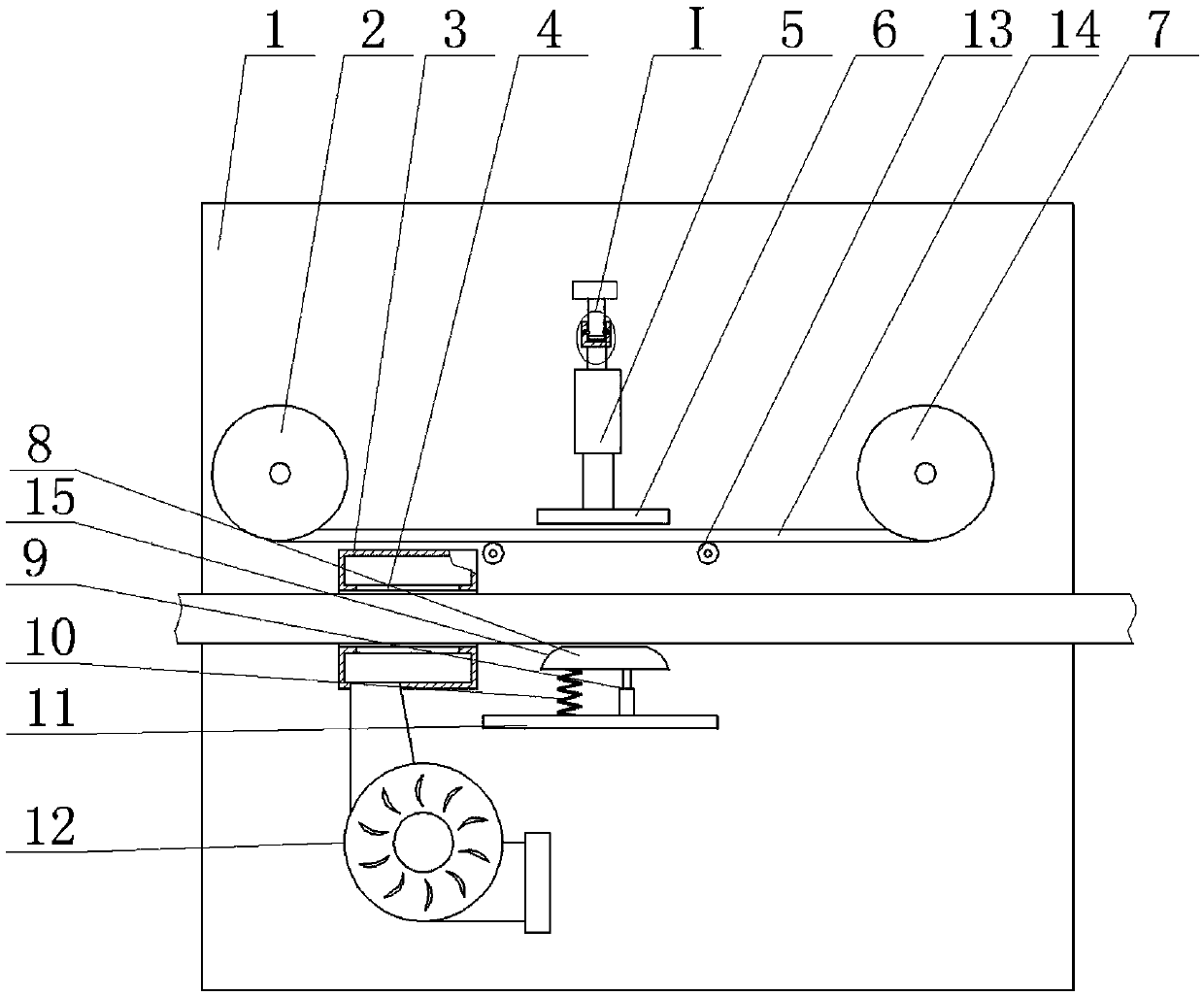

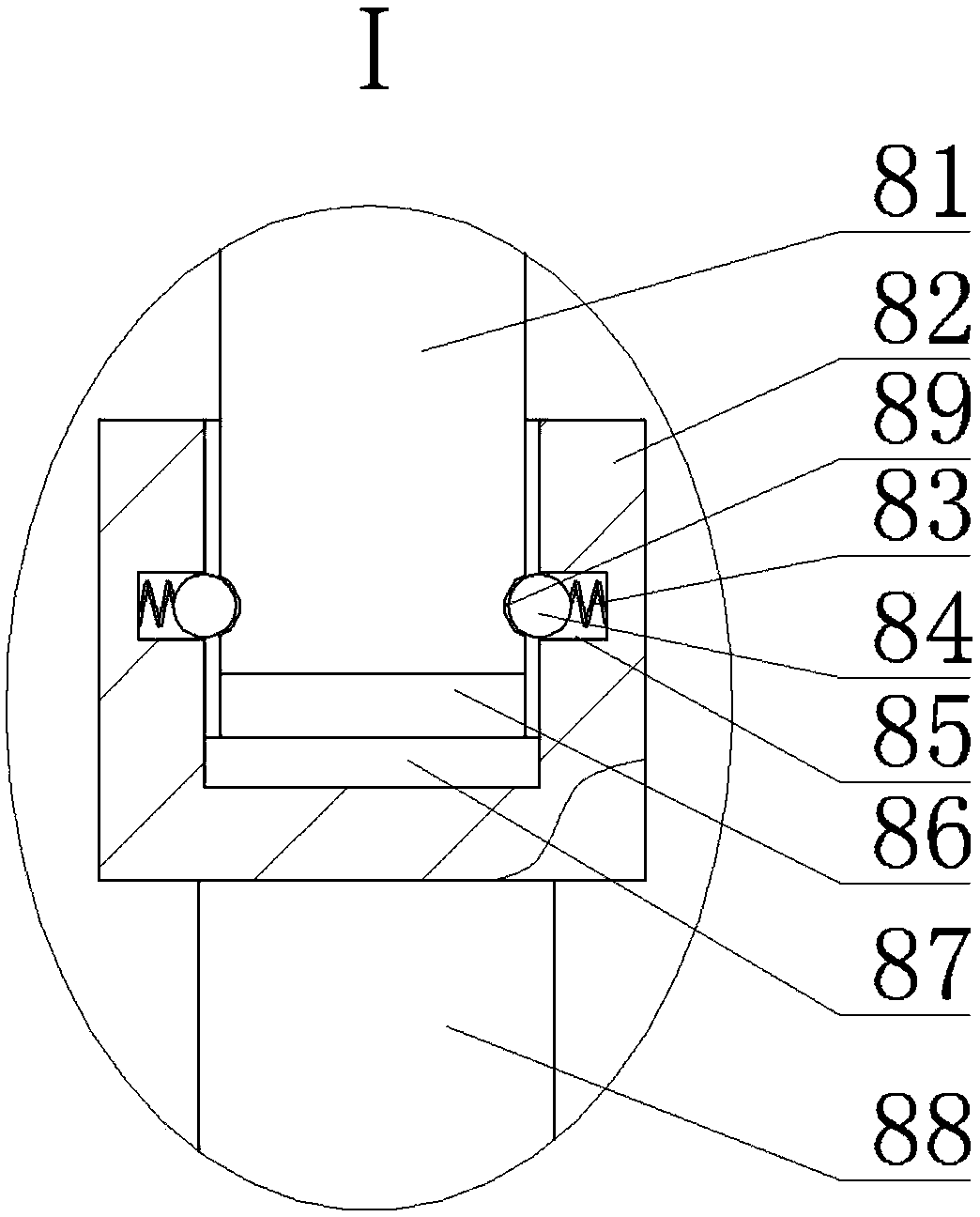

[0009] Such as figure 1 , figure 2 and image 3 As shown, a low-frequency cable assembly crimping system labeling device includes a chassis 1, on which a labeling roller 2, a storage roller 7, an electric push rod 5, an annular tube 3 and a buffer bracket device are installed, and the labeling The labeling belt 14 is installed on the roller shaft 2, and one end of the labeling belt 14 is connected to the storage roller 7, the labeling belt 14 is in a horizontal state, and the end of the push rod of the electric push rod 5 is installed with a pressure plate 6, and the pressure plate 6 is located on the labeling belt 14 Above, the buffer bracket device includes a fixed plate 11, the fixed plate 11 is installed on the cabinet 1, the upper part of the fixed plate 11 is equipped with a telescopic rod 9 and a spring 10, the upper end of the telescopic rod 9 and the upper end of the spring 10 are connected to the base 8, Arc-shaped surfaces 15 are arranged on both sides of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com