Touch display screen with high-strength corners

A touch display, high-strength technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problem of UV light energy attenuation, full-fit OCA, low viscosity, and can not be fully-fitted OCA is completely cured and other problems to achieve the effect of improving adhesive strength and preventing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

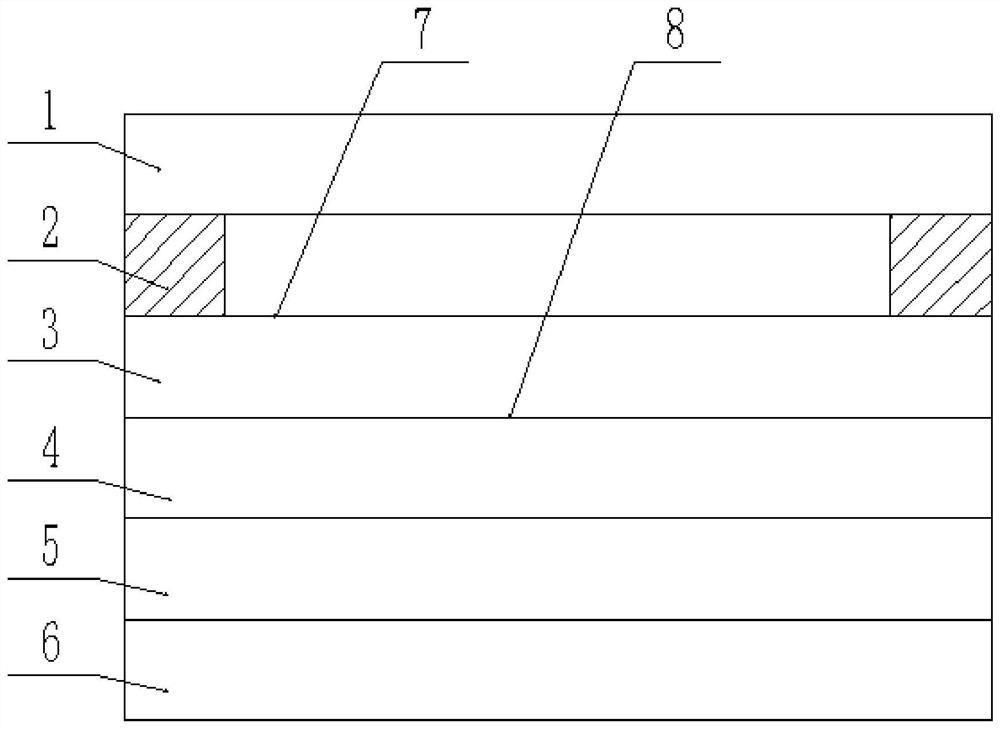

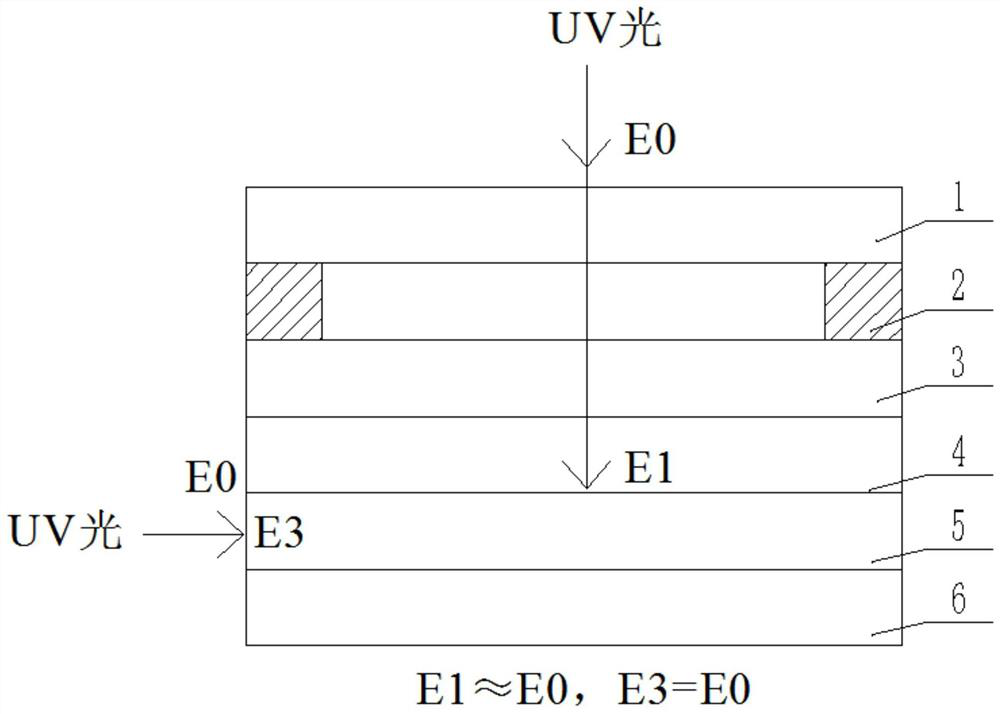

[0026] refer to Figure 1-2 , a high-strength corner touch display screen, including a cover plate 1, an ink layer 2, an adhesive 3, a capacitive sensing layer 4, a full-fit OCA5 and a liquid crystal display module 6, the cover plate 1, the ink layer Layer 2, adhesive 3, and capacitive sensing layer 4 form a touch screen TP7, and the touch screen TP7 and the liquid crystal display module 6 form a touch screen 8 after being bonded by the full lamination OCA5. The four corners of the screen 8 increase UV side curing.

[0027] Further, the cover plate 1 is made of any one of glass material, PET material, 2.5D, and 3D cover plate, and PC, PMMA, and TAC materials cannot be used, because these PC and other materials have a blocking effect on UV light, When the UV light reaches the surface of the cover, it will be blocked by the PC material. The UV-type full-bonded OCA cannot receive UV light, so that the fully-bonded OCA in the visible area and the ink area of the touch screen ca...

Embodiment 2

[0037] refer to Figure 5 , a high-strength corner touch screen UV curing method 2. This curing method requires 4 UV curing lamps to be fixed on the four corners respectively. The curing process does not need to move the UV curing lamp. The shape of the UV curing lamp is L-type, both directions of L-type can emit UV light, and irradiate two sides of the four corners at the same time.

Embodiment 3

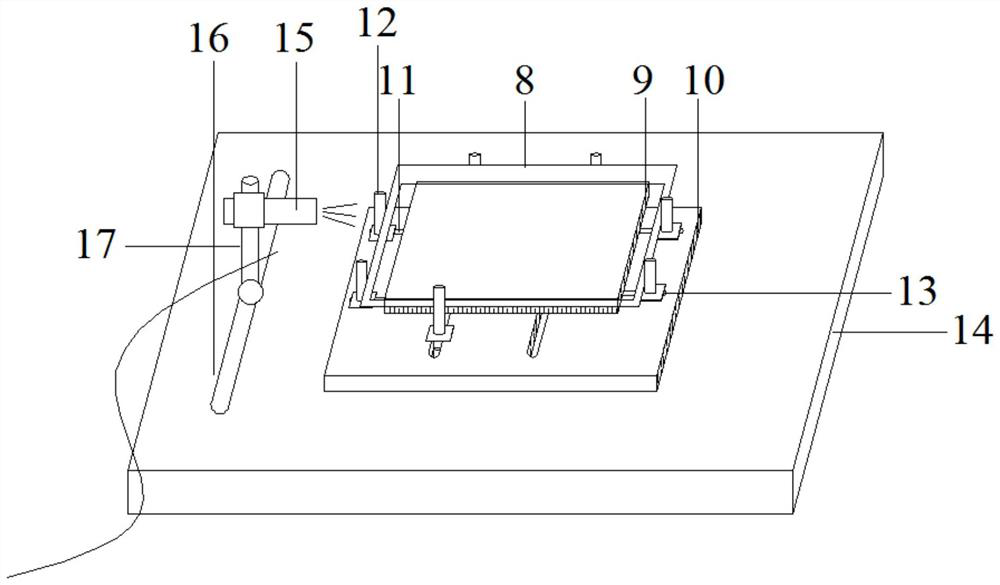

[0039] refer to Image 6 , a high-strength corner touch screen UV curing method 3, this curing method only needs 1 UV curing lamp, the shape of the UV curing lamp is a straight shape, and only one direction can emit UV light. Fix the UV curing lamp on one side 11 of the first corner of the touch display screen for light curing; after UV irradiation is completed, move the horizontal screw 16 to move the UV curing lamp to the other side 12 of the first corner for curing. Illumination curing; after completing the UV irradiation, move the horizontal screw 16 to move the UV curing lamp to one side 21 of the second corner for light curing; after completing the UV irradiation, move the horizontal screw 16 to move the UV curing lamp to the second side 22 places on the other side of the corner for light curing; after UV irradiation is completed, move the horizontal screw 16 to move the UV curing lamp to one side 31 of the third corner for light curing; after completing the UV irradiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com