Feeding device of binding machine

A technology of feeding device and wire binding machine, which is applied in the direction of thin material handling, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of the overall weight of the cable and the difficulty of the operator's feeding process, so as to improve production efficiency , reduce loading and handling, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

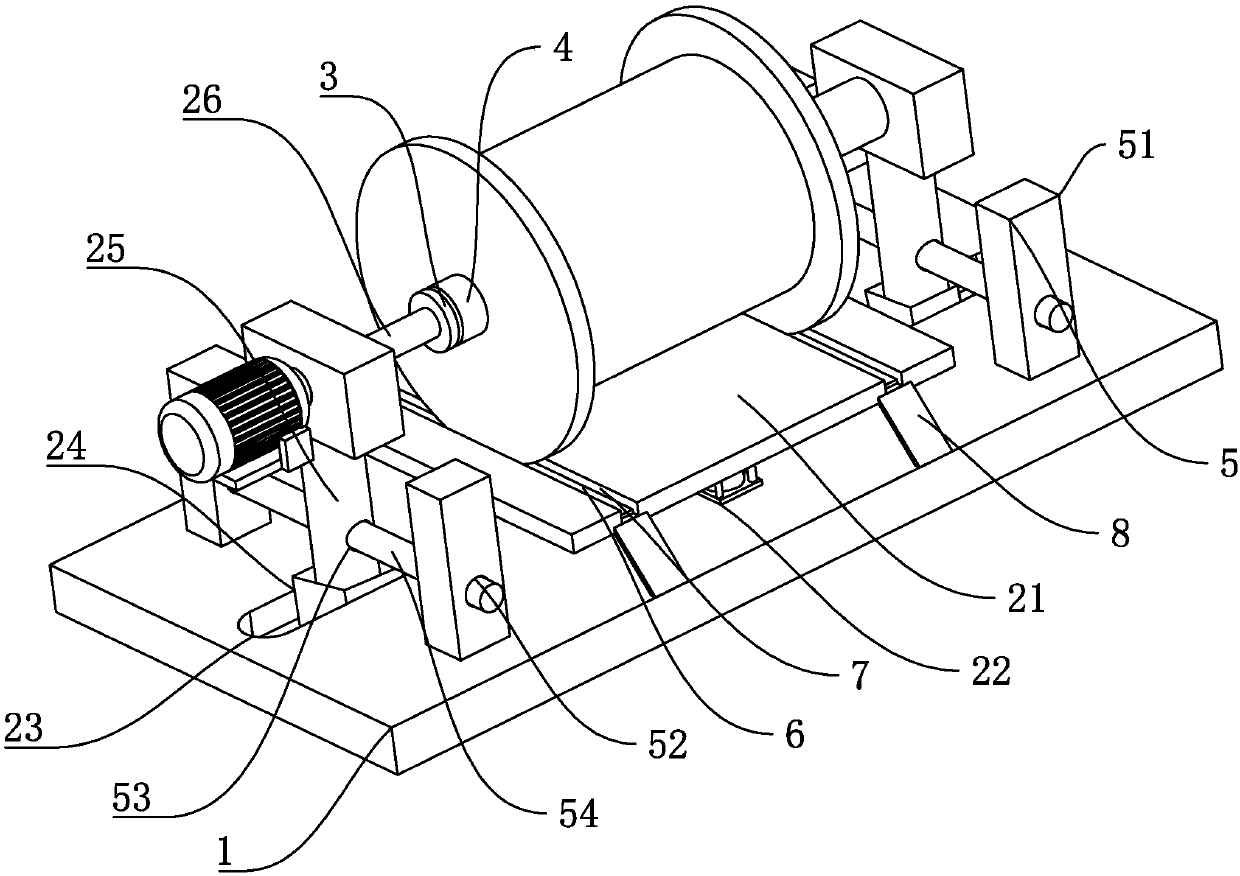

[0023] Embodiment 1: a kind of wire binding machine feeding device, such as figure 1 Shown, comprise frame 1, be provided with feeding device 2 on frame 1, feed device 2 comprises the base 21 that is positioned at the middle of frame 1, is provided with lifting cylinder 22 at the bottom of base 21, the machine on both sides of base 21 The frame 1 is also provided with a chute 23, and a block 24 matching the chute 23 is stuck in the chute 23, and the block 24 is provided with a support rod 25, and the top of the support rod 25 is arranged to rotate with the support rod 25. The connected rotating rod 26 is also provided with a rotating motor fixedly connected with the rotating rod 26 on the frame 1, and at the same time, an outwardly protruding edge 3 is also provided on the end of the rotating rod 26 away from the motor, and the edge 3 is wrapped with Rubber spacer 4.

[0024] Frame 1 is also provided with fixing device 5, and fixing device 5 comprises the support base 51 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com