High Iron zinc calcine process method

A treatment method, high-iron-zinc technology, applied in the field of zinc smelting, can solve the problems of resource waste, production cost not economically feasible, high equipment requirements, etc., achieve the effect of reducing production cost, having economic feasibility, and reducing material handling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

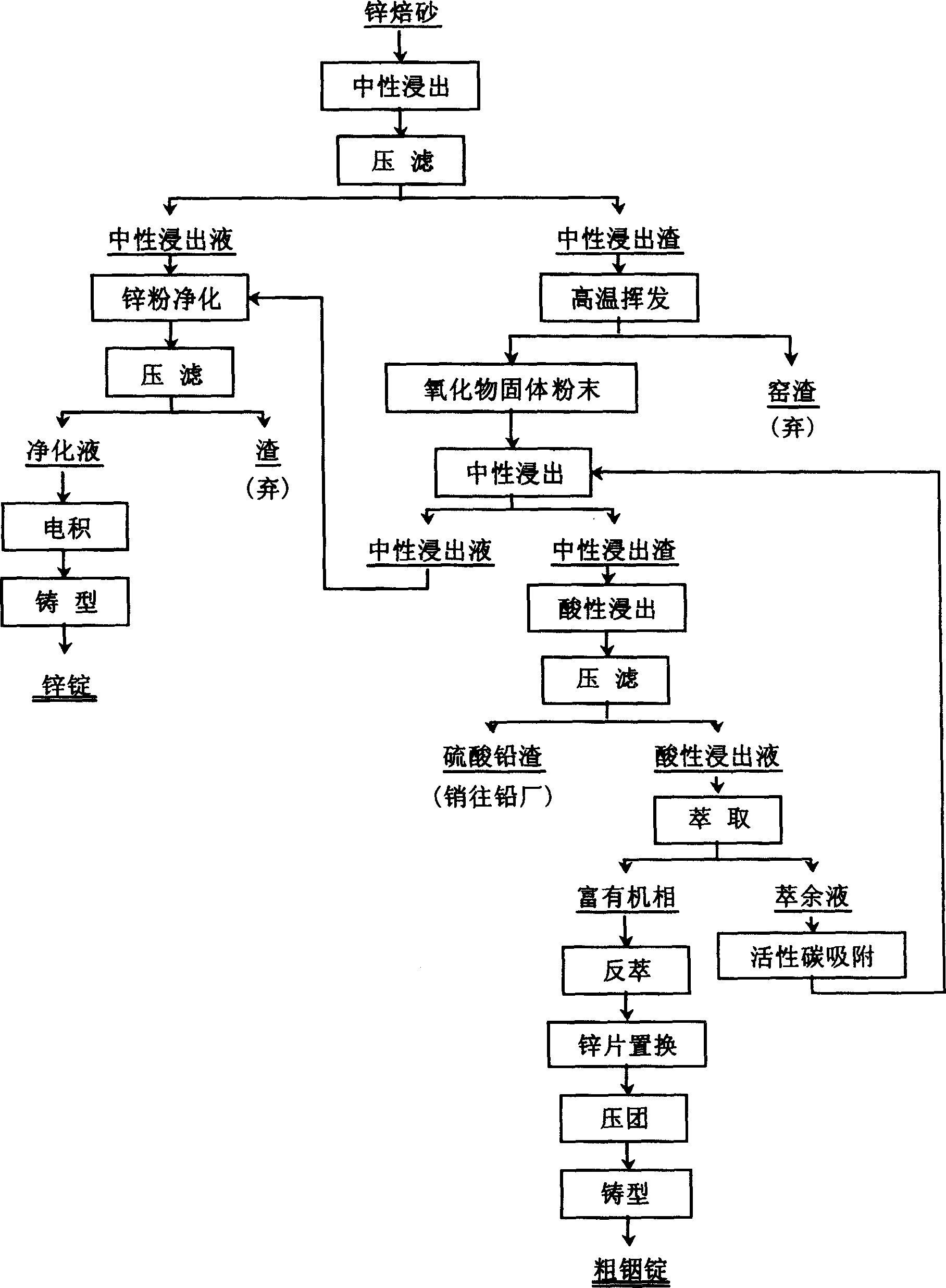

Image

Examples

Embodiment 1

[0038] The present invention is used to process the high-iron zinc calcined sand with the following weight percentages: Zn54.18%, Fe20.20%, In0.043%, Cu0.62%, Cd0.78%, and Pb3.21%. conduct:

[0039] Step 1: The high-iron zinc calcine is subjected to neutral leaching treatment in a conventional leaching equipment according to a conventional method, and the pH value is adjusted to 4.5. After using a filter press to obtain a neutral leachate and a neutral leach residue, the neutral leachate is pressed by The conventional method is to add zinc powder to purify and remove impurities, and then carry out electrowinning to obtain precipitated zinc flakes, which are then cast into molds to obtain products that meet the requirements of GB / T470-1997 for Zn99.995 zinc ingots;

[0040] Step 2: Mix the neutral leaching slag and coke powder obtained in step 1 in a weight ratio of 2:1, mix well, add to the ignited and heated Wei's furnace, blow in air, and raise the temperature to 1300 degree...

Embodiment 2

[0045]The processing composition of Example 1 is the following percentage by weight Zn54.18%, Fe20.20%, In0.043%, Cu0.62%, Cd0.78%, Pb3.21% high-iron zinc calcined sand, the difference is : in the step, the PH value is adjusted to 5.4; in the step 2, the neutral leaching slag is mixed with coal and limestone in a weight ratio of 2:1:0.2, and the coal used is coal with a calorific value of 23000kJ / kg, and the mixture is heated in the furnace Inner residence time is 5 hours, and gained metal oxide solid powder component is zinc 60.56%, lead 9.32%, indium 0.28%, and slag zinc content is 1.65%; In the step 4, sulfuric acid solution concentration is 1.9mol / l, and temperature is 80 degrees, the obtained acidic leaching residue contains 58.88% of lead sulfate; the indium content in the crude indium obtained in step 5 is 98.89%.

Embodiment 3

[0047] Processing composition is following percentage by weight Zn54.18% by embodiment 1, Fe20.20%, In0.043%, Cu0.62%Cd0.78%, the high-iron-zinc calcine of Pb3.21%, difference is:

[0048] In the step, the pH value is adjusted to 5; in step 2, the neutral leached slag is mixed with coke powder and limestone in a weight ratio of 4:1:1, the mixture stays in the furnace for 3 hours, and the temperature is raised to 1000 degrees, and the obtained metal The oxide solid powder component is 59.06% of zinc, 8.90% of lead, 0.27% of indium, and the zinc content of slag is 2.50%. The concentration of sulfuric acid solution in step 4 is 2.0mol / l, and the temperature is 70 degrees. Lead sulfate 58.70%; the indium content in the crude indium obtained in step 5 is 98.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com