Building construction using braced frame slab assemblies having heavy perimeter rails

a technology of bracing frame slab and perimeter rail, which is applied in the direction of girders, walls, joists, etc., can solve the problems of reducing the dimensional limitation, and reducing the lateral (shear capacity) of the wall, so as to reduce the loss of breakage and damage, the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

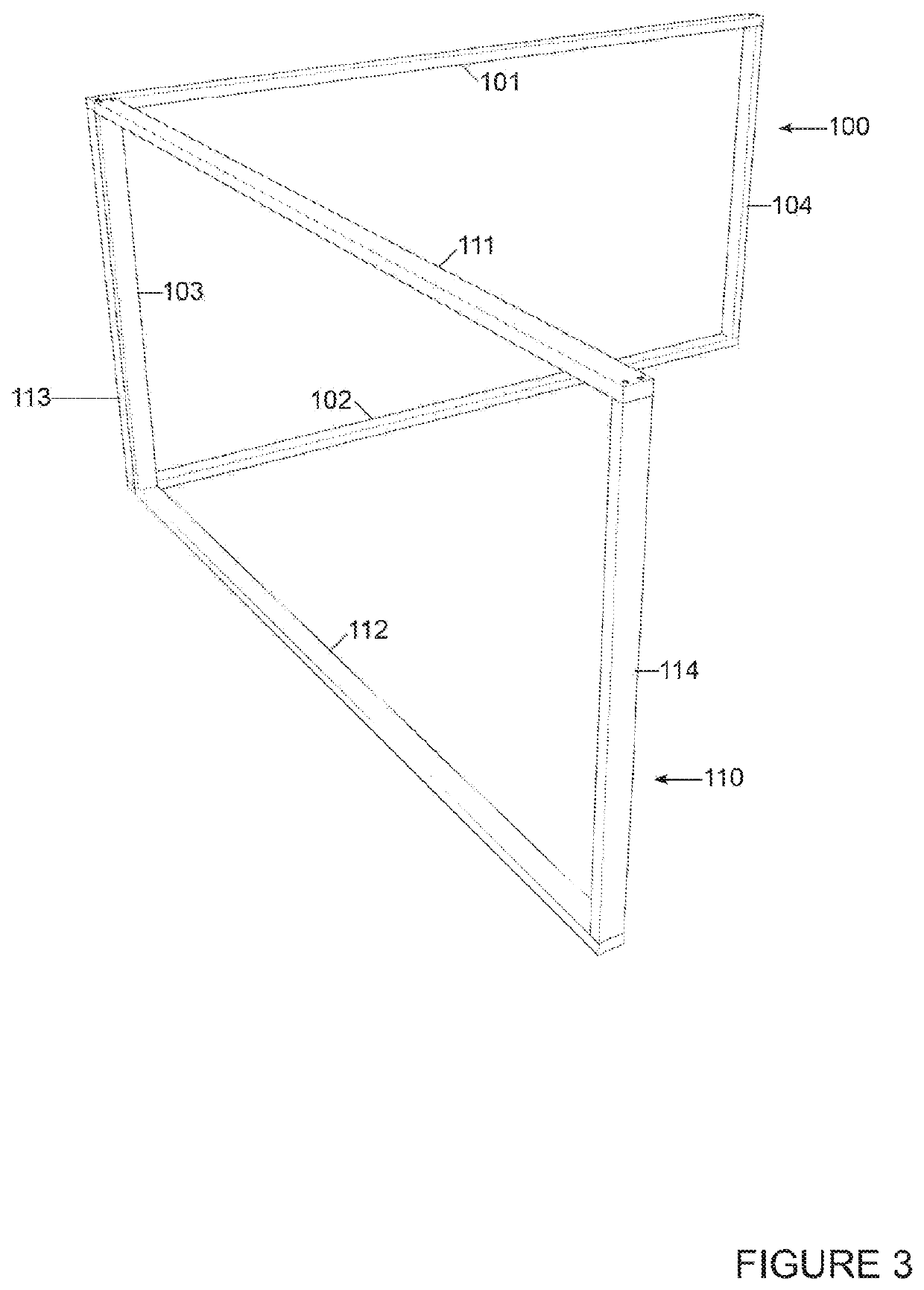

[0045]The standard framing paradigm used in conventional construction is a “braced frame” structure where the bracing is provided via the OSB sheathing that covers the floors and walls once they are secured in place. Standard framing utilizes a uniform sheathing on both floors and walls (except at door and window openings) to create a braced frame (a.k.a. a diaphragm). The emphasis in this type of construction is the continuity of the OSB sheathing across the full extent of the wall and floor elements. For example, each of the parts in a wall frame is dedicated to a specific purpose—bottom plate, full studs, trimmer studs, headers, top plate, etc. There are no pieces in this structure that support another purpose—i.e. for the primary structural attachment of adjoining independent panelized components.

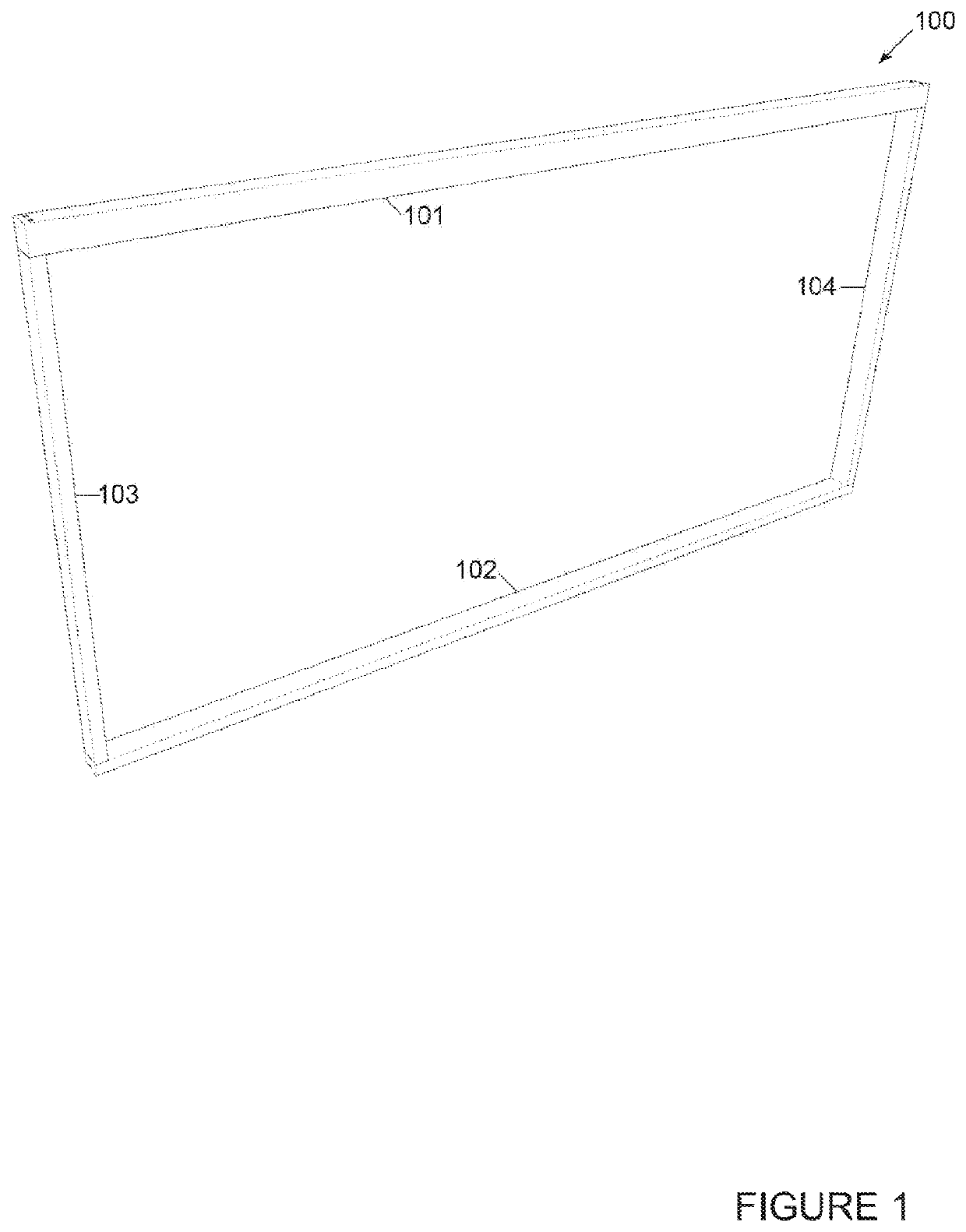

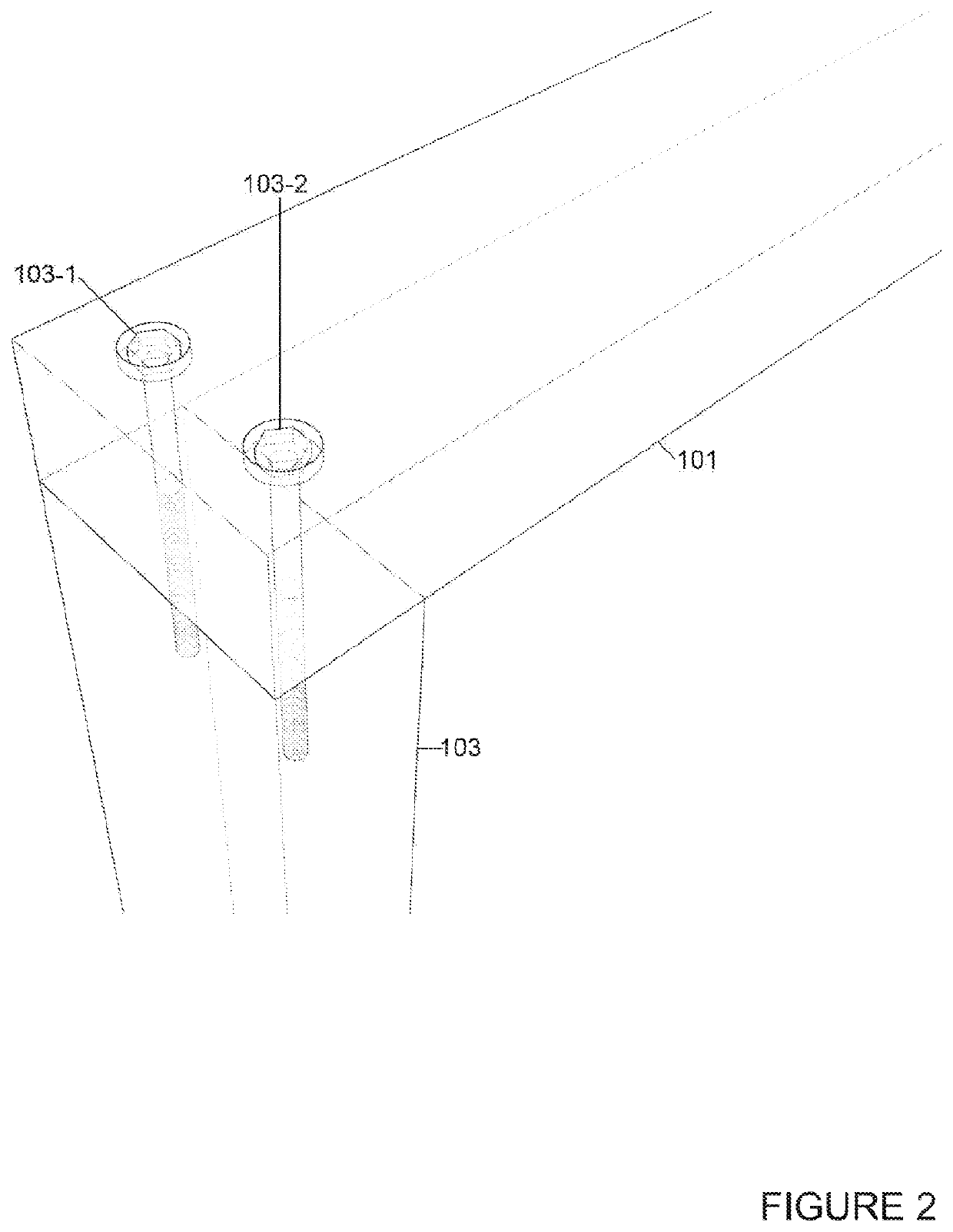

[0046]In contrast, the present Braced Frame Slab Assemblies Having Heavy Perimeter Rails incorporates heavy perimeter Rails for this purpose, which is a fundamental distinction over the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com