Mounting and construction method of U-shaped tunnel pipelines

A technology of pipeline installation and construction method, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of high safety hazard, difficult to guarantee installation quality, long construction period, etc., to improve work efficiency and reduce The effect of working time and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

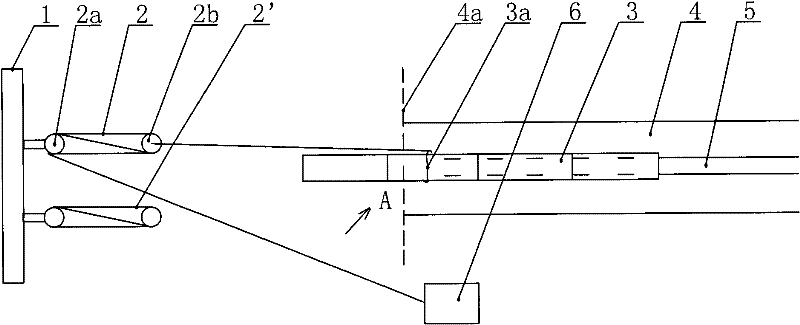

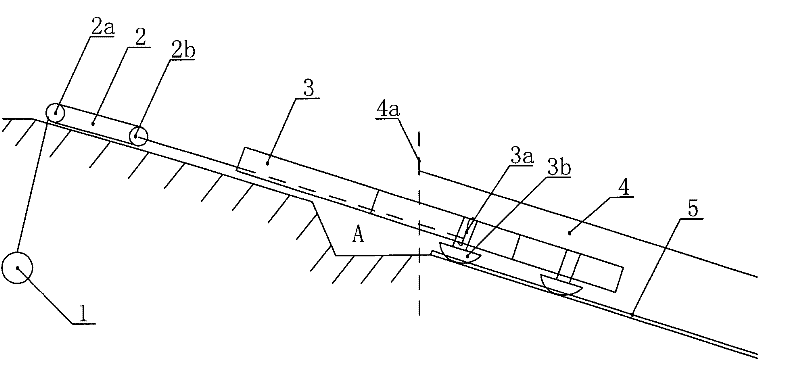

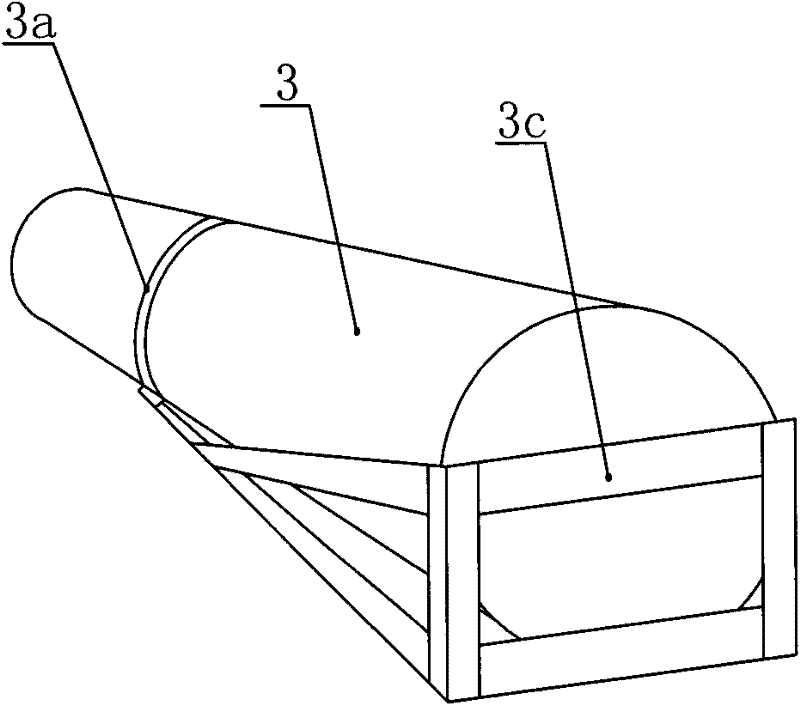

[0012] The U-shaped tunnel includes left inclined shaft section, level road section and right inclined shaft section. like figure 1 , figure 2 As shown in the figure, the U-shaped tunnel pipeline installation and construction method of the present invention includes the following steps: firstly, the pipeline installation of the left-inclined well section is carried out, and at the same time, the pipeline transportation and distribution of the roadway section is carried out. The pipelines in the right inclined well section are installed and finally connected at the level road section.

[0013] The pipeline installation steps of the inclined shaft section are as follows: (1) Lay a light rail at the bottom of the tunnel inclined shaft 4 as a guide device for the pipeline to slide down; (2) bury a ground anchor 1 capable of carrying the pipeline slide load in front of the tunnel mouth 4a, and at the bottom of the tunnel 4a. Fix the hoist in a proper position; (3) excavate the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com