U-shaped steel bushing shed structure for roadway support

A roadway support and section steel technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as increased roadway maintenance costs, non-uniform effects, and accelerated roadway damage, so as to reduce roadway maintenance costs and improve stability and support. The effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

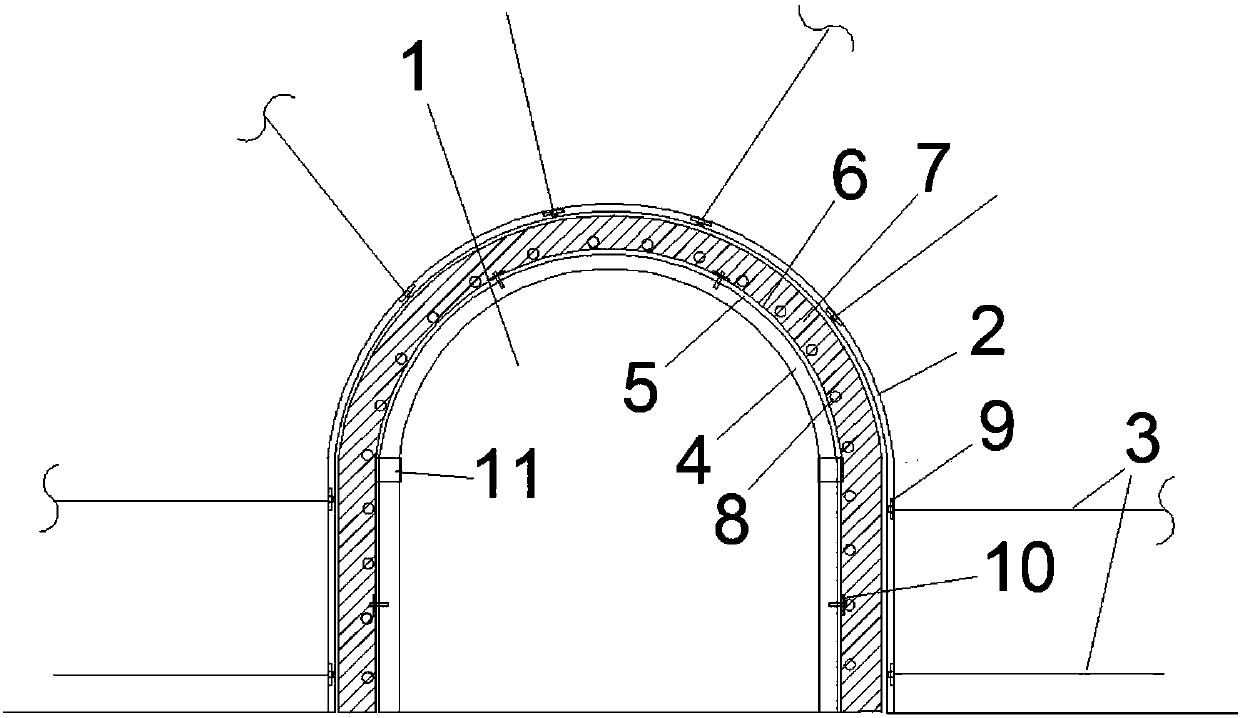

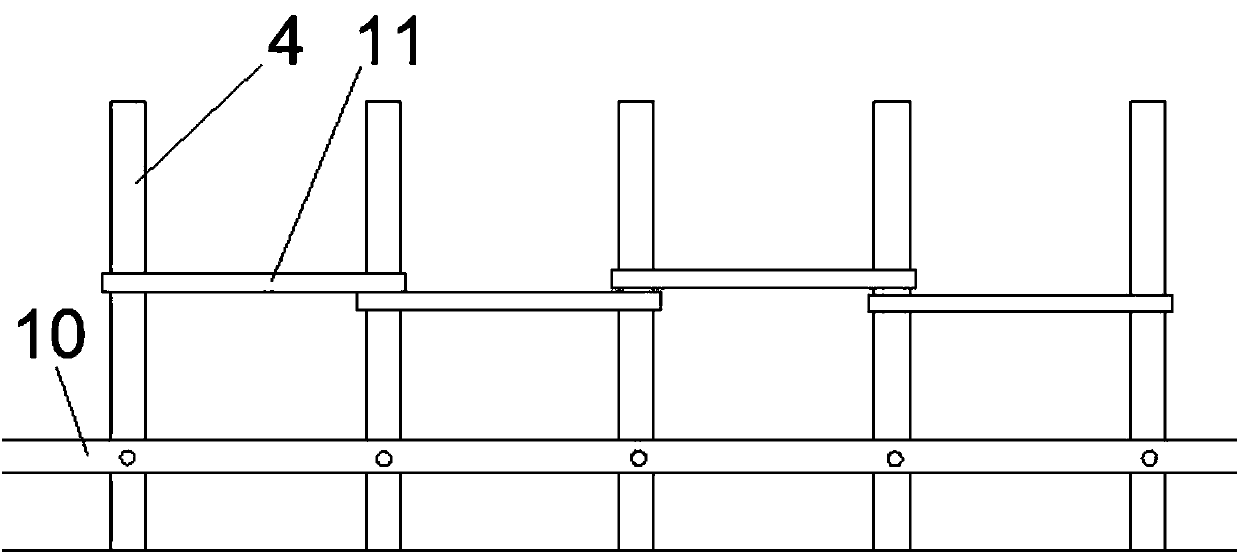

[0013] Refer to attached figure 1 and 2 , this embodiment provides a U-shaped steel shed structure for roadway support, including a metal mesh 2 hung on the surrounding rock surface of the roadway 1, and the metal mesh 2 is fixed on the surrounding rock surface of the roadway 1 through anchor cables 3, and the roadway The top plate and the surrounding rock of 1 are provided with anchor cable holes, one end of the anchor cable 3 is anchored in the surrounding rock through the anchor cable hole, and the other end is fixed on the inner side of the metal mesh 2 through the tray 9, and the inner side of the metal mesh 2 passes through the roadway. 1 Inverted U-shaped steel 4 sets of shed support with matching cross-sections, U-shaped steel 4 is arranged at equal intervals along the length direction of the roadway 1, and U-shaped steel 4 is fixedly connected by connecting rods 10, and two adjacent U-shaped steel 4 The connection between them is strengthened by the clamp cable 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com