Broken surrounding rock and soft rock roadway U-shaped steel sleeve shed support method

A technology for crushing surrounding rock and section steel, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as increased roadway maintenance costs, non-uniform action, and accelerated roadway destruction, so as to reduce roadway maintenance costs, improve stability and The effect of support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

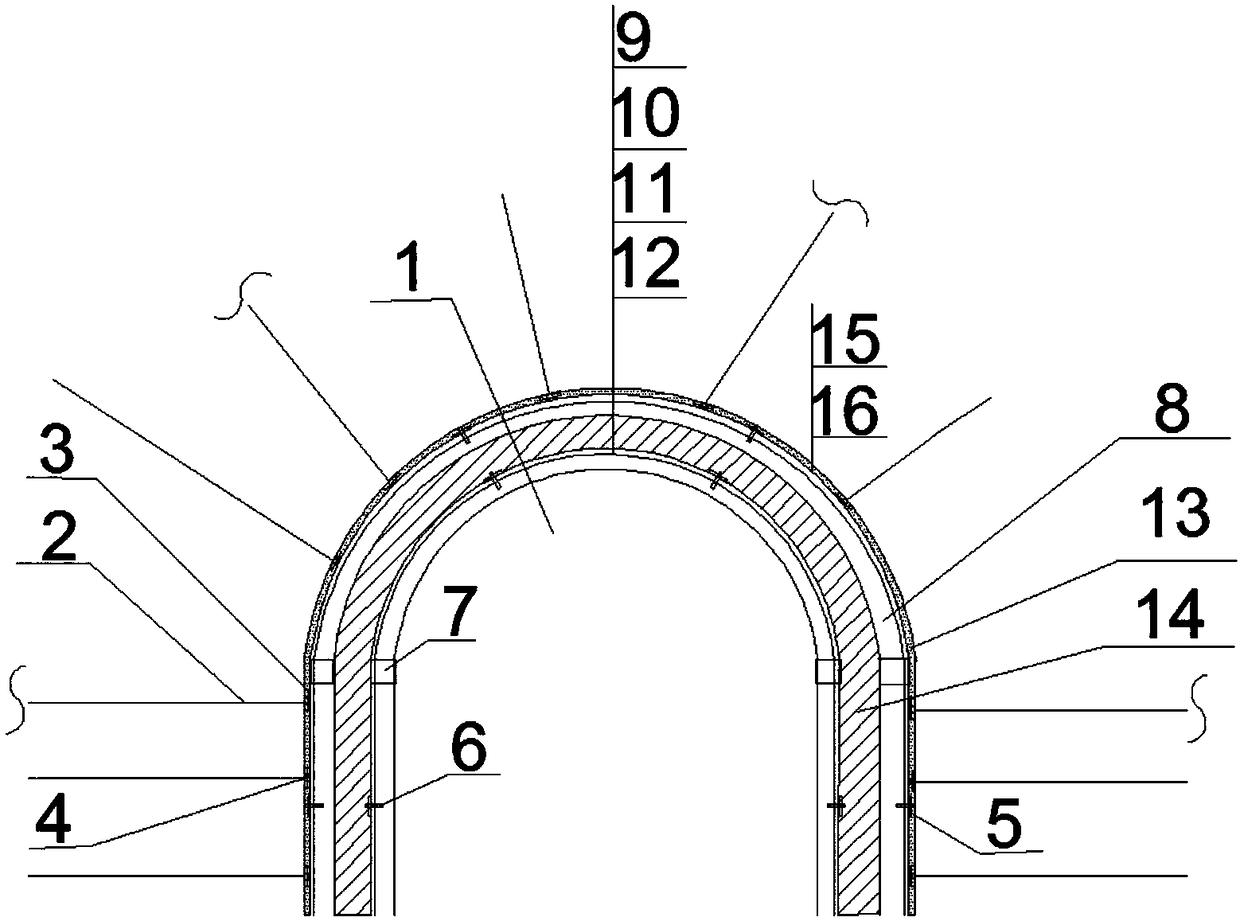

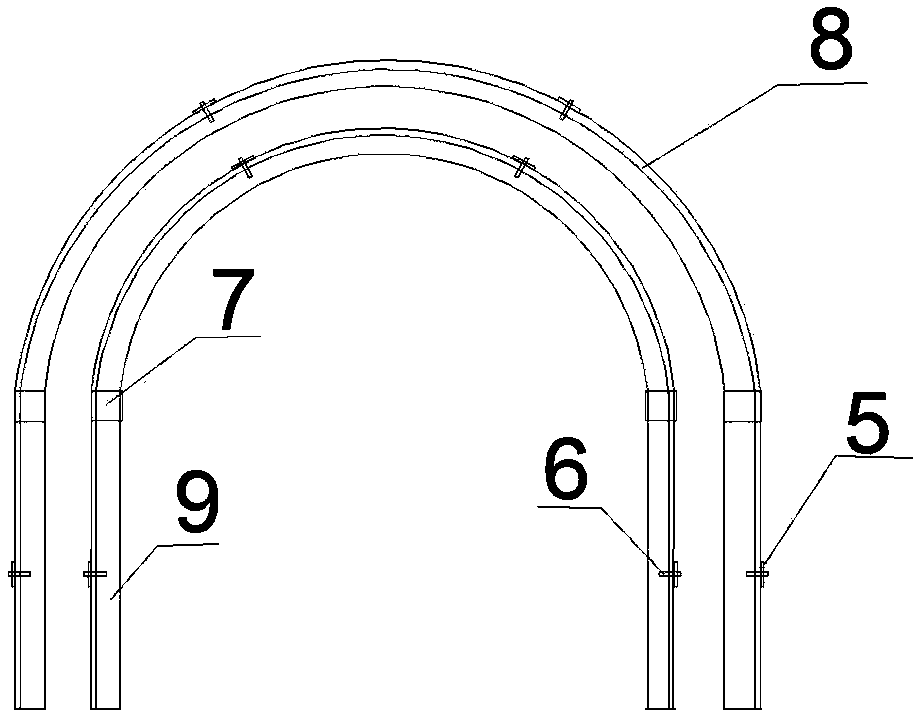

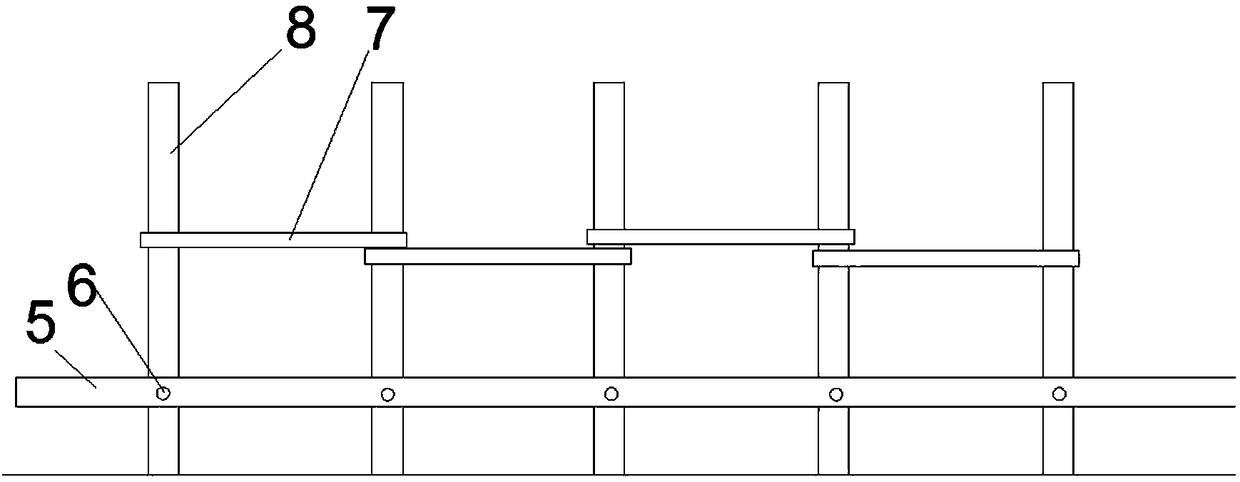

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0022] The invention provides a U-shaped steel shed support method for broken surrounding rock and soft rock roadway. The specific steps are as follows:

[0023] Step 1: After the roadway 1 is excavated, knock on the roof immediately, drill the anchor cable hole on the roof of the roadway 1 and the surrounding rock, and install the anchor cable 2 with strong prestress. The length of the high-strength prestressed anchor cable 2 is 6m, and the row spacing 1200×1200mm, pre-tightening force 55-80KN; metal mesh 15 is hung on the surrounding rock surface and steel bar ladder 16 is arranged in a right-angled way. Install the anchor cable tray 3, make it pass through the anc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com