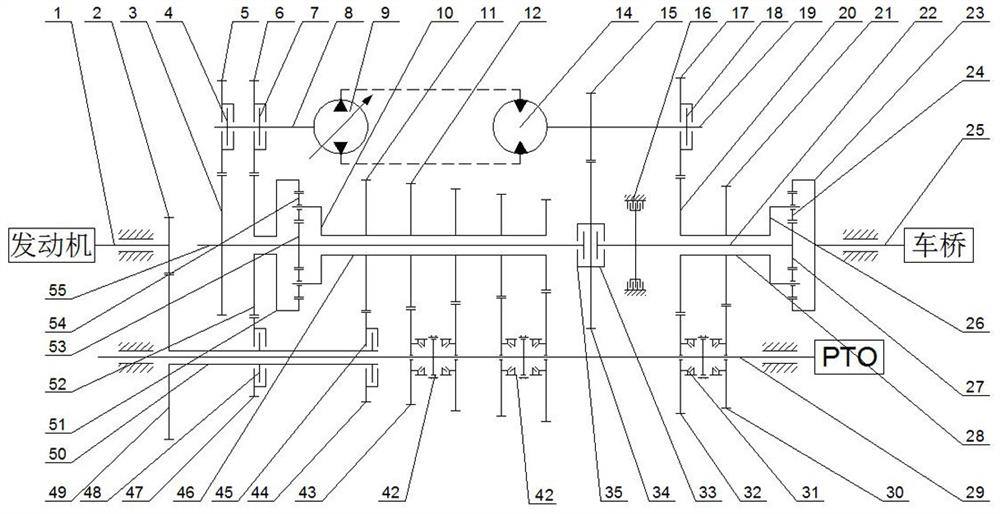

A multi-stage multi-mode continuously variable transmission for high-power vehicles

A continuously variable transmission, multi-mode technology, applied in the direction of transmission, components with teeth, gear transmission, etc., can solve the problems of low processing and assembly accuracy requirements, high performance requirements of hydraulic components, complex control, etc., and achieve a simple structure. The effect of compactness, increased shifting range, and flexible switching control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

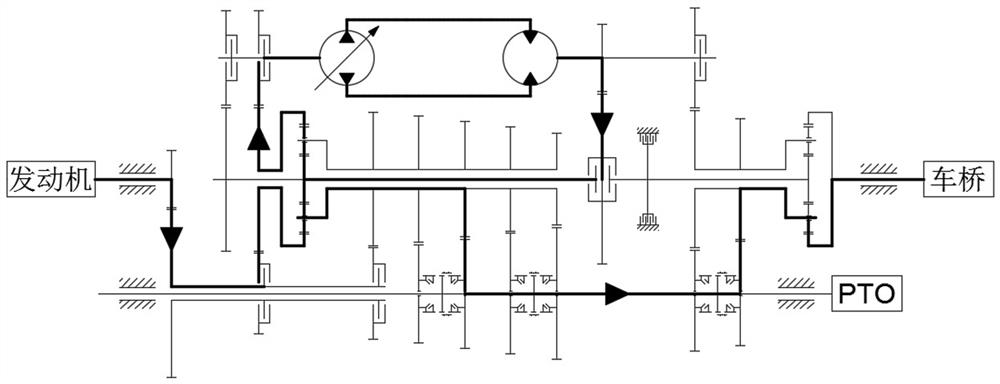

Embodiment 1

[0029] Embodiment 1. The transmission process of the first torque-fraction-combined-speed hydraulic-mechanical hybrid mode of a multi-stage multi-mode continuously variable transmission for high-power vehicles is as follows: specifically, as figure 2 As shown, the power transmitted from the engine is transmitted to the first hollow shaft 50 through the first gear 2 and the second gear 49, the sixth gear clutch 48 is closed, and the power is realized at the front ring gear 52 through the sixth gear 47. All the power is transmitted to the hydraulic circuit through the fifth gear 6 and the closed fifth gear clutch 7, and then the front sun shaft clutch 35 is combined, and the power is transmitted to the front through the seventeenth gear 15, the eighteenth gear 34, and the front sun shaft 55. The sun gear 53; the other power is located on the front ring gear 52; after the two powers converge on the front planetary row, they pass through the front planet carrier 10, the second hol...

Embodiment 2

[0033] Embodiment 2. The transmission process of the second split-torque combined-speed hydraulic-mechanical hybrid mode of a multi-stage multi-mode continuously variable transmission for high-power vehicles is: specifically, as image 3 As shown, the power transmitted from the engine is transmitted to the first hollow shaft 50 through the first gear 2 and the second gear 49, the sixth gear clutch 48 is closed, the eighth gear clutch 45 is closed, and the third gear clutch 4 is closed, so that the power Moment splitting is realized at the first hollow shaft 50; power is transmitted to the hydraulic circuit through the front ring gear 52 and the fifth gear 6, and the rear sun shaft clutch 33 is combined, and then the power is transmitted to the rear sun gear through the rear sun shaft 22 27; One way of power is transmitted to the first ninth gear 12 from the right and the tenth gear 43 from the right through the second hollow shaft 46, and the first synchronizer 42 on the right ...

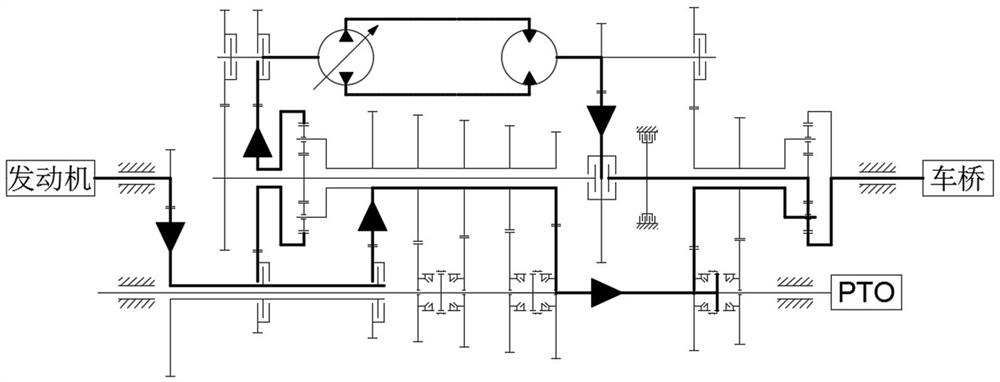

Embodiment 3

[0037] Embodiment 3. The transmission process of the split-speed converging moment hydraulic-mechanical hybrid mode of a multi-stage multi-mode continuously variable transmission for high-power vehicles is: specifically, as Figure 4 As shown, the power transmitted from the engine is transmitted to the first hollow shaft 50 through the first gear 2 and the second gear 49, the sixth gear clutch 48 is closed, the third gear clutch 4 is closed, and the power is transmitted to the front planetary row to realize the speed Divide; One way of power passes through the front sun gear 53, the front sun shaft 55, the fourth gear 3, the third gear 5, and the closed third gear clutch 4, and the power is transmitted to the hydraulic circuit. The nineteenth gear clutch 18 is combined, and then the power The nineteenth gear 17, the twentieth gear 20, and the third hollow shaft 28 are transmitted to the rear planet carrier 26; all the power is transmitted to the second ninth gear 12 from the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com