A flange structure suitable for underwater electromagnetic ejection device

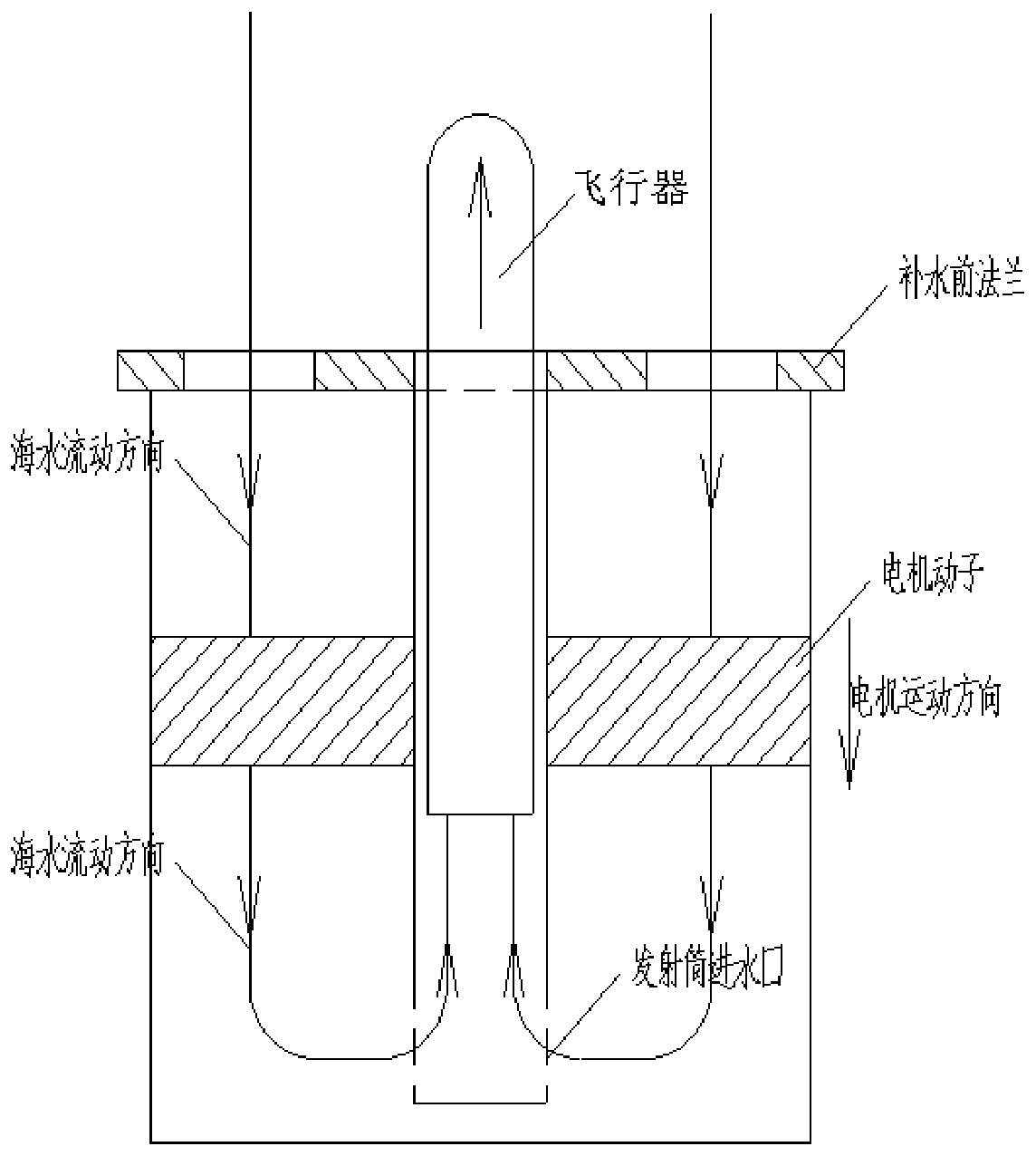

An electromagnetic catapult and flange technology, applied in the field of launch, can solve the problems such as the introduction of seawater outside the boat, and achieve the effects of simple structure, reduced thrust loss, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

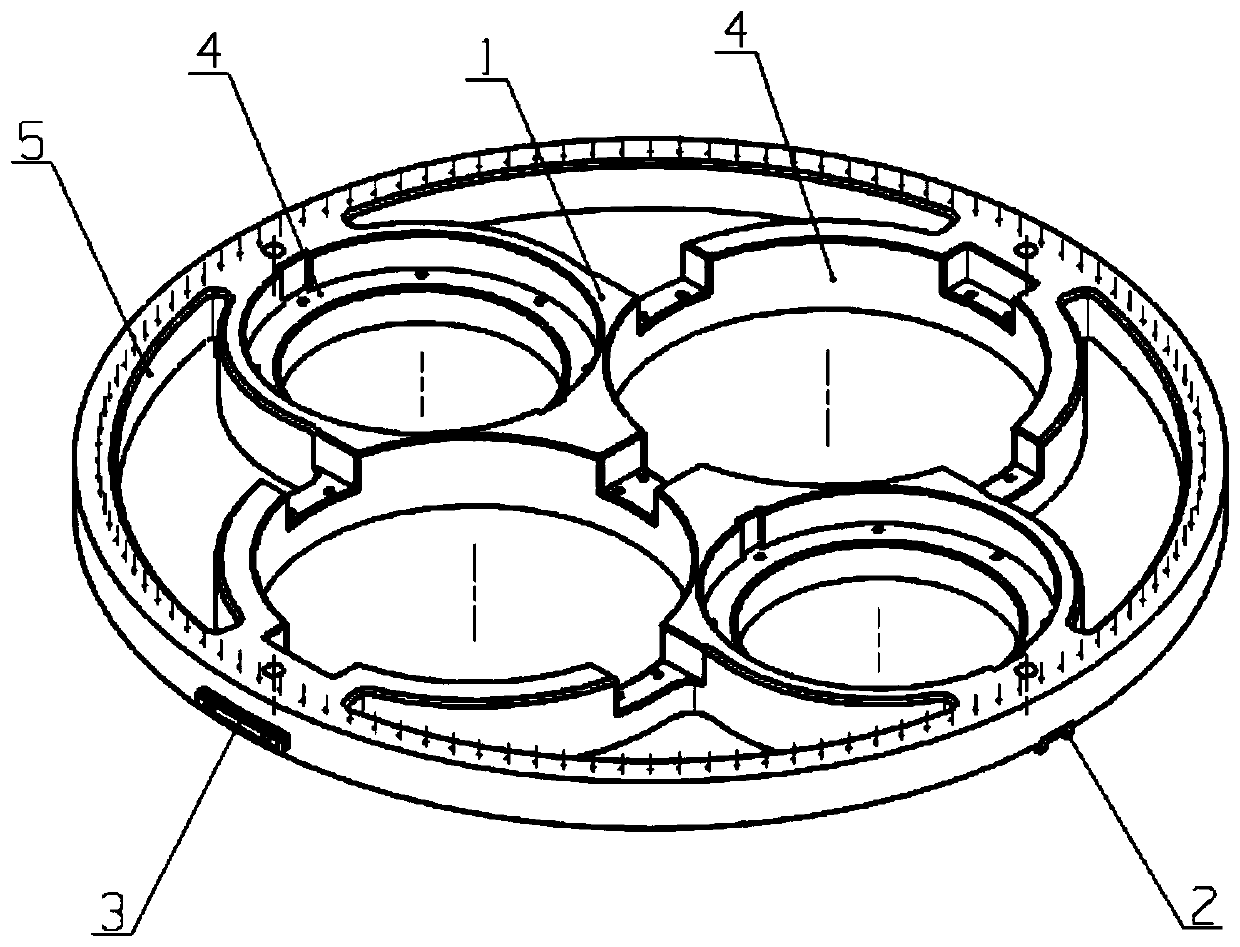

[0015] Such as figure 1 As shown, the present invention provides a schematic diagram of the flange structure suitable for underwater electromagnetic ejection devices. This structure is used to provide an interface for installing and fixing the launch tube of the aircraft when the launching device is stored and transported, and it is installed and fixed on the launching device. on the device. The structure includes a flange body 1 , a connecting cylinder positioning block 2 , and a flange circumferential positioning block 3 .

[0016] The flange body 1 is made of precipitation hardened stainless steel. The connecting cylinder positioning block 2 is two pieces, which are arranged on the bottom of the flange body 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com