An integrated low-power consumption tri-axial magnetic field sensor with high Z-direction resolving force

A magnetic field sensor and resolution technology, which is applied in the field of weak magnetic signal detection, can solve the problems of low compensation efficiency and insufficient resolution in the Z direction, and achieve the effects of simple implementation, improved resolution, aggregation amplification and planar measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

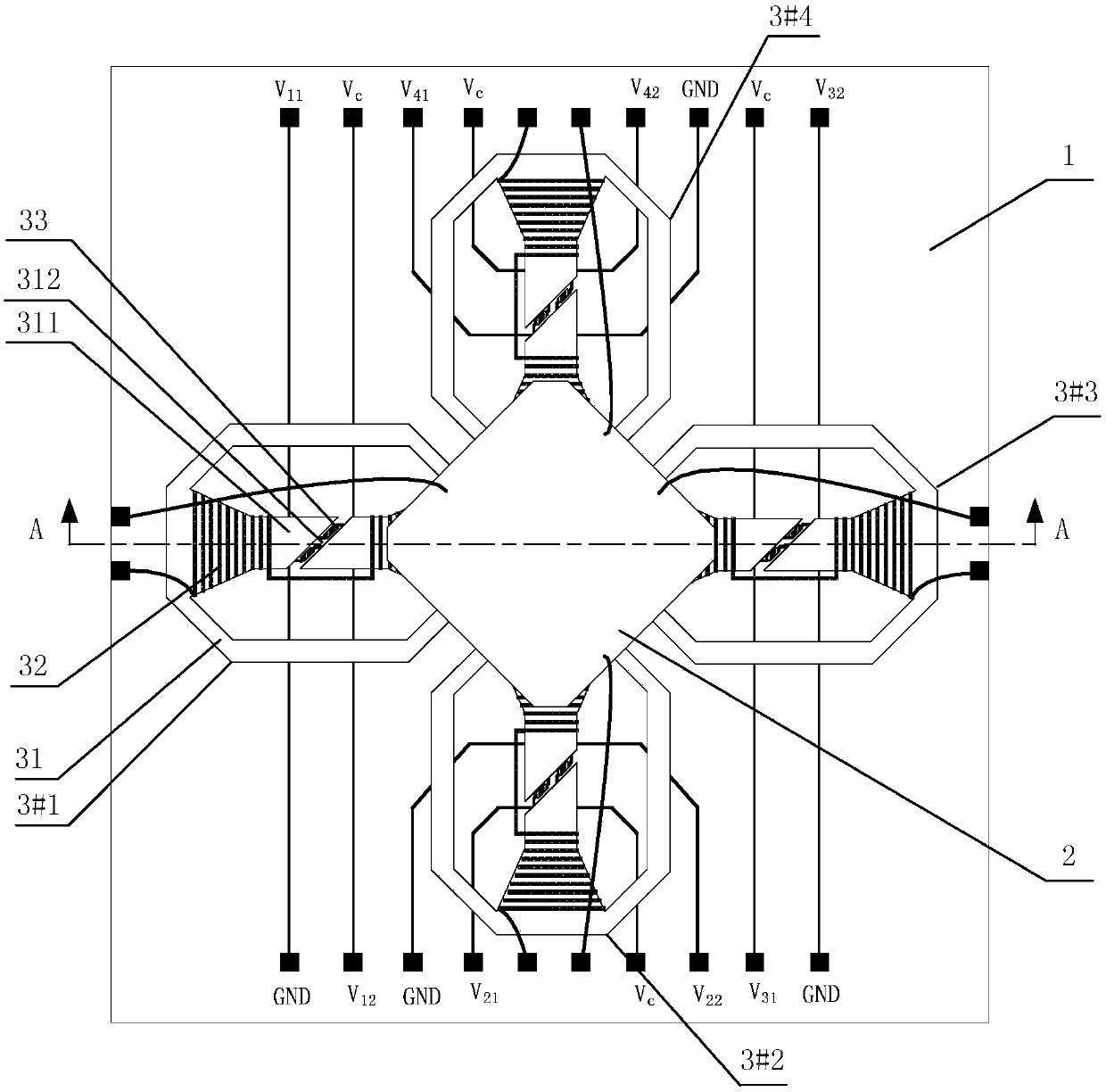

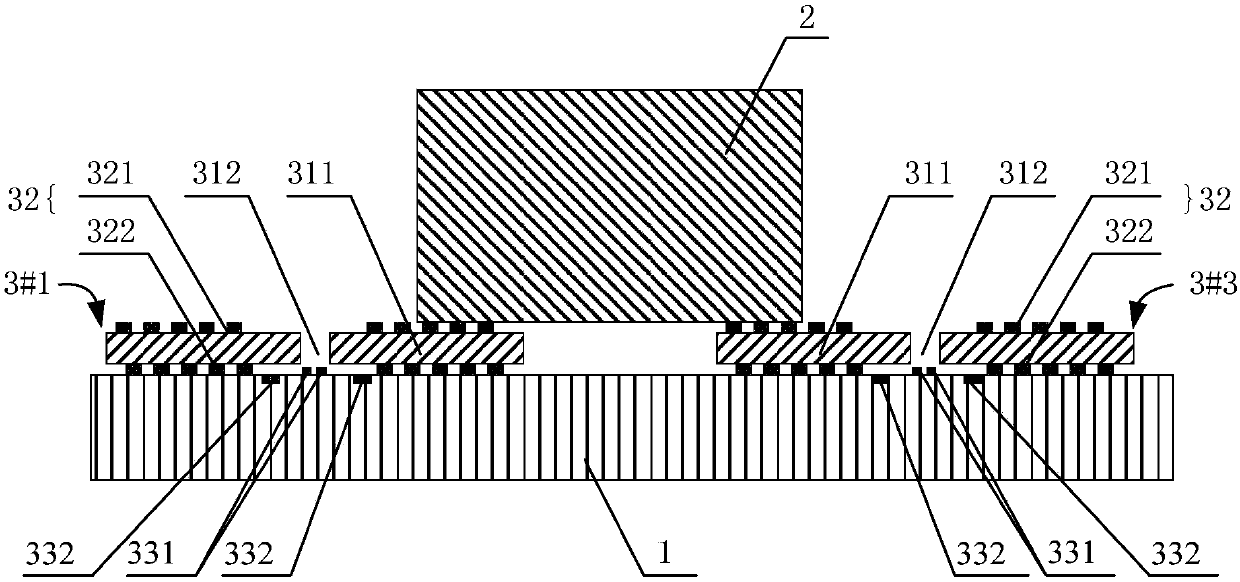

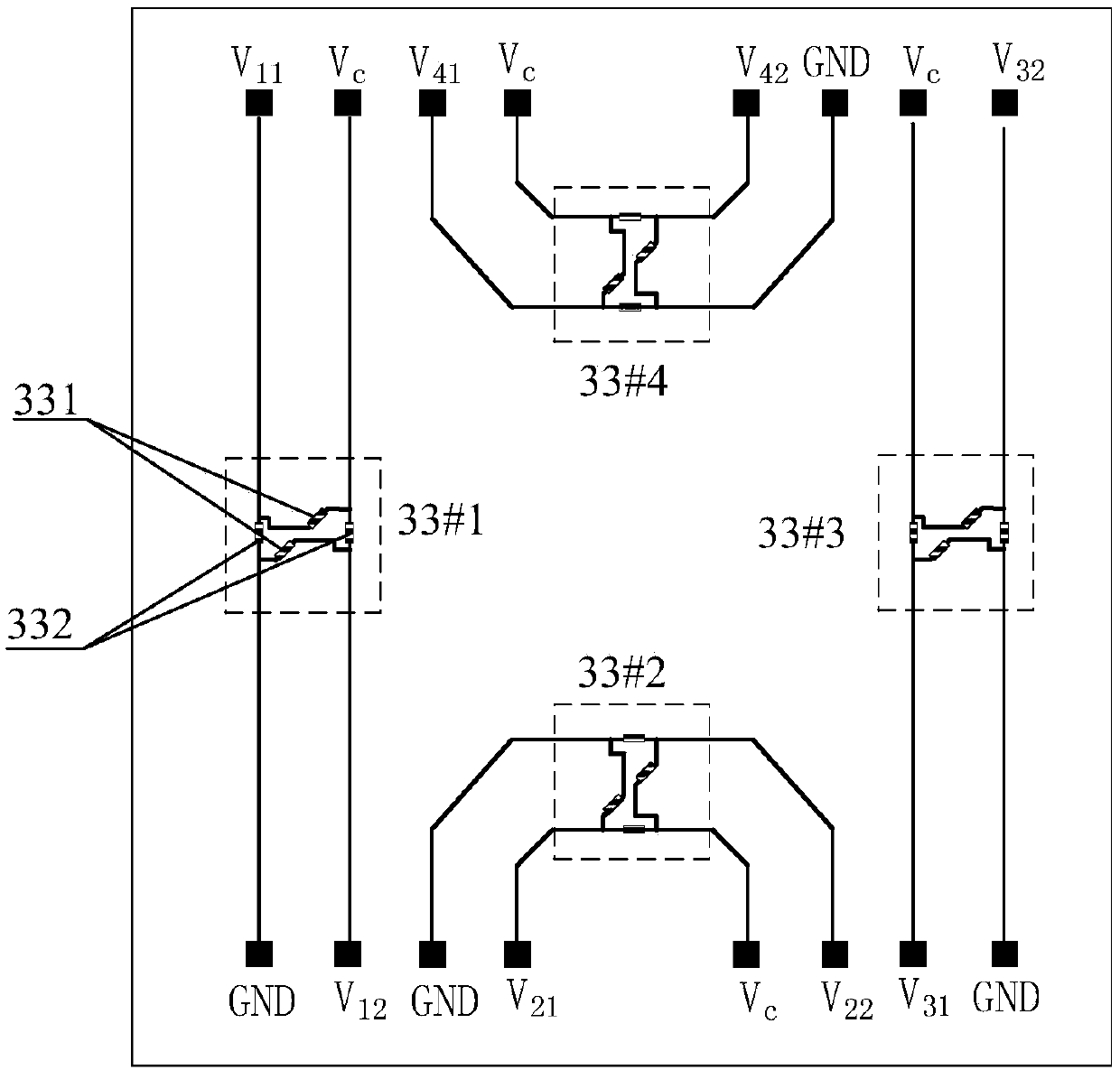

[0028] Such as figure 1 As shown, the integrated low-power three-axis magnetic field sensor with high Z-direction resolution of this embodiment includes an insulating substrate 1, a track-changing soft magnetic block 2, and four magnetic measurement units 3 (magnetic measurement units 3#1 to magnetic measurement Unit 3#4), four magnetic measurement units 3 (magnetic measurement unit 3#1 ~ magnetic measurement unit 3#4) are symmetrically arranged on the surface of the insulating substrate 1, and the track-changing soft magnetic block 2 uses four magnetic measurement units The center point of 3 is symmetrically placed on the four magnetic measurement units 3 , and a part of each magnetic measurement unit 3 is located directly below the track-changing soft magnetic block 2 . The integrated low-power three-axis magnetic field sensor of this embodiment uses the track-changing soft magnetic block 2 and four magnetic measurement units 3 to realize high-efficiency track changing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com