A Principal Component Analysis Modeling Method for Cracking Reaction Furnace Temperature

A principal component analysis, cracking reaction technology, applied in the field of automatic industrial process control, can solve the problem of difficulty in modeling the temperature object of cracking furnace and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Taking the temperature of the cracking reactor as the actual object, taking the opening of the fuel valve as the input, and taking the temperature of the cracking reactor as the output, the model of the cracking reactor temperature is established.

[0047] The steps of the inventive method comprise:

[0048] Step 1. Collect the real-time operation data of the process and establish the improved neural network model of the process object. The specific steps are as follows:

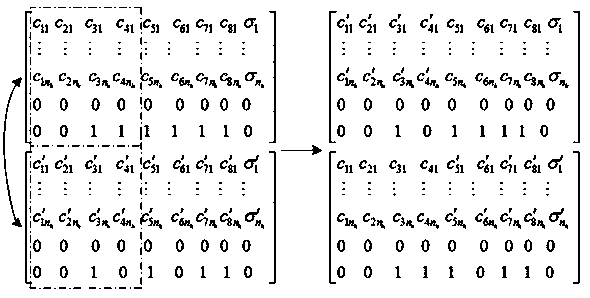

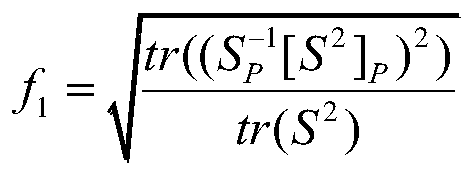

[0049] 1-1. According to the established model and comprehensive principal component analysis method, the optimal solution for a given subset p is obtained in the following form:

[0050]

[0051] Among them, S is the covariance matrix of the data, S 2 The square of the covariance matrix, S P Select p×p subarrays of p variables in S in . To find the inverse of a matrix, tr() finds the trace of the matrix in parentheses.

[0052] Transform it into a minimization problem denoted as J 1 , of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com