One-batch multi-piece management mode product tracking method and photovoltaic production system

A product tracking and management mode technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the problems of cell batch confusion, inability to accurately track the production process, and inability to data data mining, etc. The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

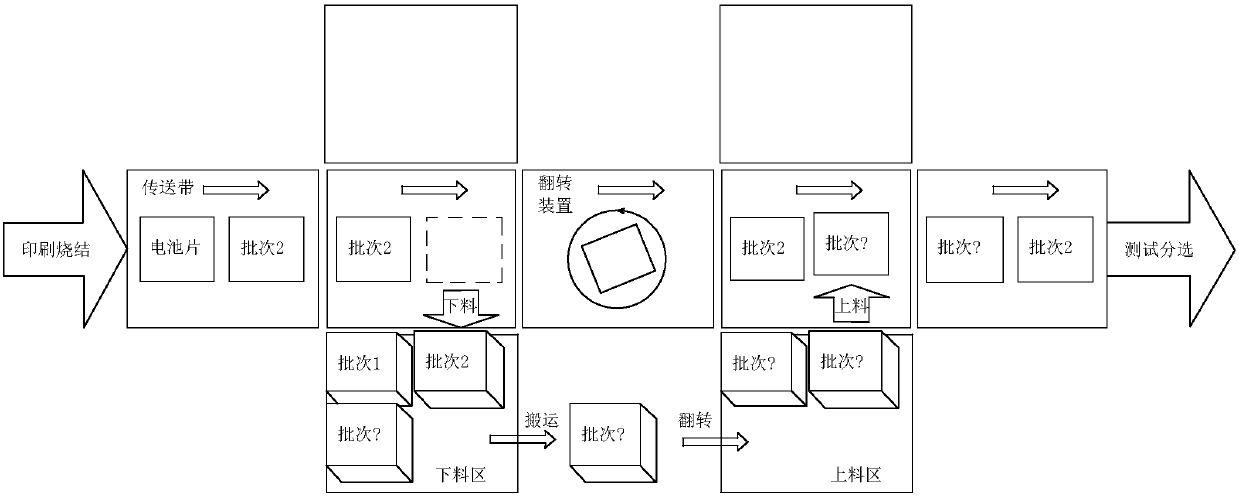

[0061] Based on the above content, this embodiment provides a product tracking method in a batch of multi-piece management mode, which is applied to the background management terminal and some equipment in the automatic production line, such as Figure 4 shown, including the following steps:

[0062] Step S100, establishing the virtual identification number of the current product, and associating the virtual identification number of the current product with the production batch number of the product;

[0063] Step S110, based on the virtual identification number and production batch number of the current product, the equipment information of the current equipment where the current product is located in the automatic production line, and the position information of the current equipment are formed into a data record and stored in the background data table;

[0064] Step S120, obtain the transfer data of the current device where the current product is located in the automatic pr...

Embodiment 2

[0082] Based on the above content, this embodiment provides a photovoltaic production system, including an automatic production line, and a background management terminal applying the above technical solution;

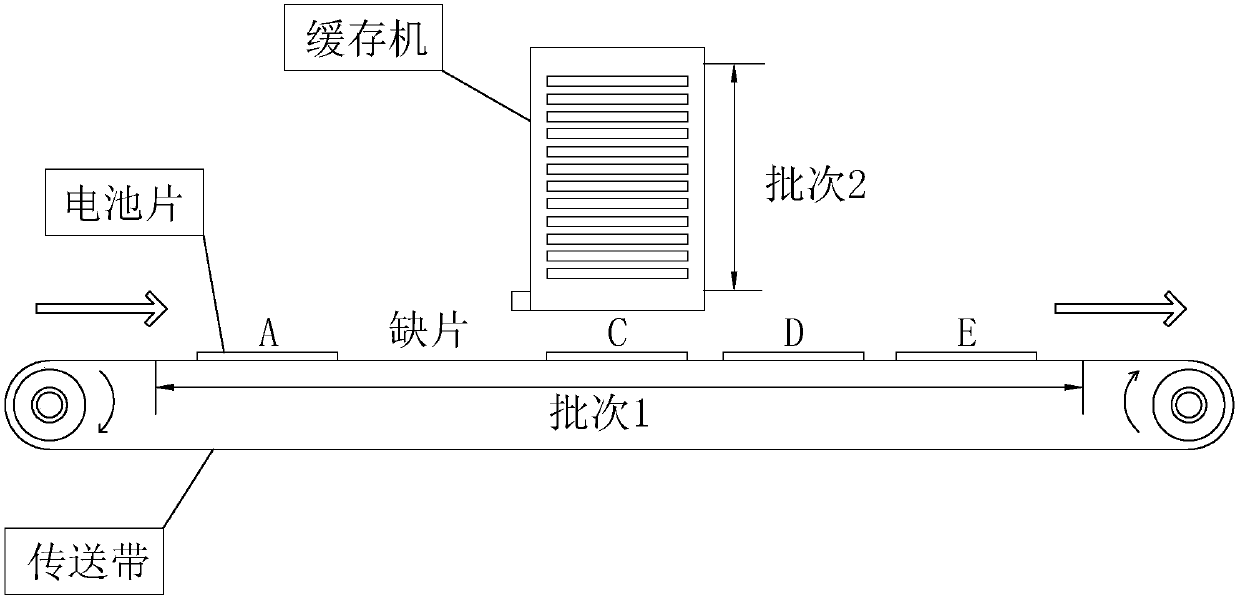

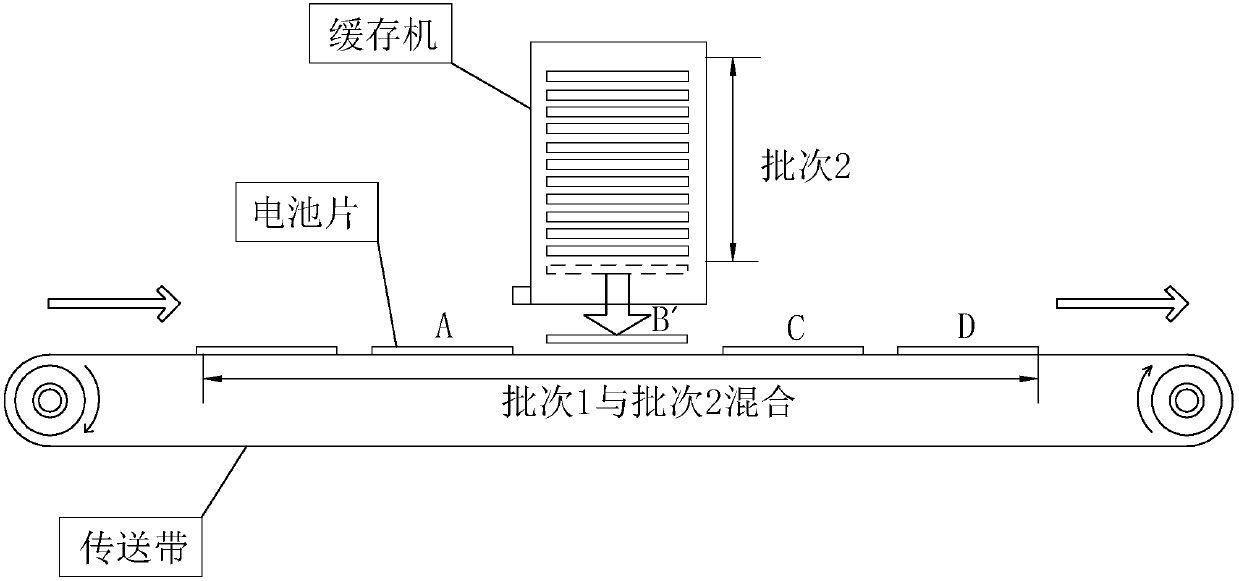

[0083] like Figure 8 As shown, the automatic production line includes a conveyor belt 1, a buffer machine 2 and a controller (not shown in the figure), the conveyor belt 1 includes several belt bodies 11, and intervals are formed between the several belt bodies 11, and the two ends of the conveyor belt 1 are driven by motors . The conveyor belt 1 is provided with several stations for product placement, and the conveyor belt 1 is provided with a first position detector 3 for outputting product position information on each station. Each first position detector 3 has a corresponding position number. When the product is placed on the station of the conveyor belt 1, the first position detector 3 detects the presence of the product to output a signal to the controller. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com